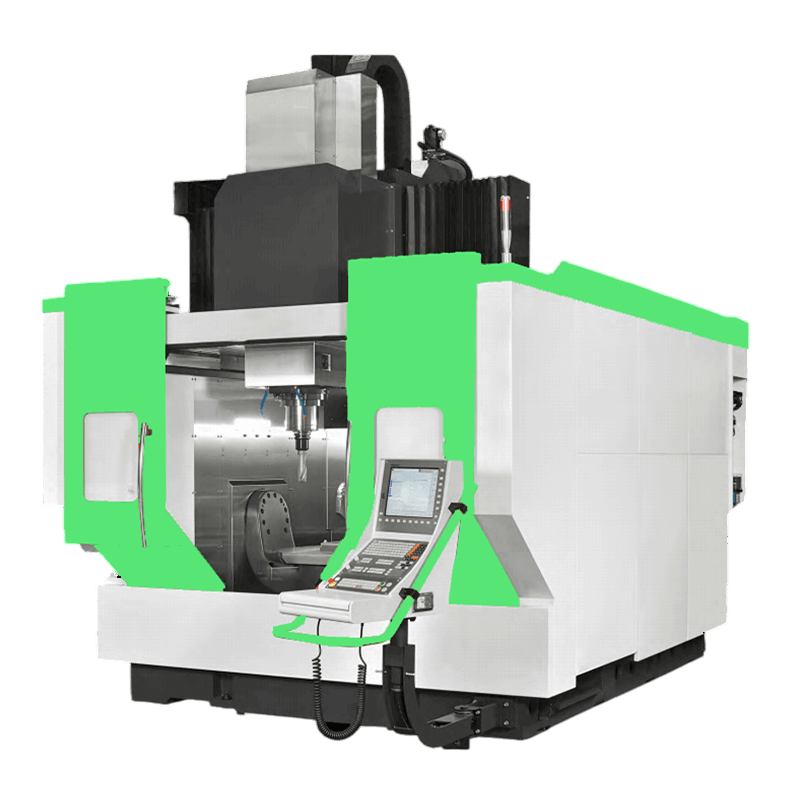

YSU-800-5X is a newly developed five-axis machining center. The machine tool has a U-shaped base structure design and a double DD direct-drive high-torque rotary table. It is suitable for five-axis machining of precision molds, precision parts and complex hardware. It is equipped with an HSK-A63/20000rpm electric spindle, which has the characteristics of high speed and low vibration, and has the ability to perform compound cutting such as precision milling, boring, drilling and tapping.

Max. X-axis Travel :

850mmMax. Y-axis Travel :

850mmMax. Z-axis Travel :

460mmMax Workpieces Weight :

1000kgApplication :

Automotive industry, mold industry, 3C productsYSU-800-5X 5-Axis Machining Center Feature

|

|

1. Equipped with German Siemens ONE system, five-axis linkage and powerful functions; 2. Equipped with Iberg φ800 dual-drive five-axis rotary worktable, it can achieve high-speed cutting processing. It adopts direct drive mode to achieve high-precision positioning without precision errors caused by worm gear transmission; 3. Strong gantry structure, high rigidity overhead crane design, Y-axis double screw drive; 4. The machine tool parts are from famous manufacturers and brands, and are equipped with top-notch configurations in the industry. 5. Five-axis parameter table |

YSU-800-5X Optomechanical Characteristics

1. The bed casting is made of HT300 resin sand, which is processed by overall annealing, natural aging and two high-frequency vibration aging treatments. It has high rigidity, high stability and long-term deformation effect;

2. Integrated beam with large span and strong support, four 45mm high-rigidity roller guides for X-axis and Y-axis, high-response screw drive technology, X/Y/Z acceleration 7m/s, X/Y/Z three-axis The standard resolution is 0.01μm optical ruler, and the X/Y/Z three-axis moving parts are separated from the processing and cutting area to ensure accuracy and service life.

3. Lathe bed base; one-piece machine casting, high rigidity, stability and efficient vibration suppression integrated base, high-standard Meehanite cast iron, secondary tempering treatment, and aging treatment for more than half a year to ensure the stability of the casting material. Precise finite element analysis and dynamics optimization technology, using grease multi-point lubrication, effectively reduce the failure rate of linear motion components and ensure the accuracy and life of the machine tool.

4. The base vertical arm strongly supports the A/C cradle rotation axis to achieve stronger guidance accuracy and rigidity.

5-Axis Machining Center Parameters

| Items | Specification | Units | YSU800-5X |

| Travel | X/Y/Z axis | mm | 850/850/640 |

| Distance from spindle nose to worktable | mm | 80-720 | |

| Orbital form | Ball Linear Guideway | ||

| Work Table | Workbench size (L*W) | mm | Ø850 |

| Maximum load-bearing capacity of workbench | kg | 1000 | |

| T-slot | No/mm | 18 | |

| Spindle | Spindle taper hole (model/installation dimensions) | mm | HSK-A63 |

| Spindle speed | rpm | 18000 | |

| Spindle transmission mode | Motorized spindle | ||

| Feed | X/Y/Z axis rapid feed | m/min | 36/36/36 |

| Maximum cutting feed | mm/min | 10000 | |

| Tool changer | Tool changing method | Side-mounted | |

| Tool holder specifications | type | HSK-A63 | |

| Tool capacity | tools | 32 | |

| Maximum tool diameter (pro-tool) | mm | 80 | |

| Maximum tool diameter (without cutting tool) | mm | 120 | |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| Fastest tool change time | sec | 2.5 | |

| Motor | Spindle motor | kw | 30KW |

| Three-axis servo motor | kw | 2.9/2.9*2/3.55 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy | Positioning accuracy | mm | 0.008 |

| Repeatability | mm | 0.006 | |

| Power Requirements | Power requirements | kva | 60 |

| Air source requirements | Kg/cm | 6~8 | |

| Machine size | Length*Width*Height | mm | 4528*2240*3650 |

| Weight | t | 21 |

Tags :