The drilling and tapping machining center series is widely used for rapid drilling, tapping, and milling of small parts such as electronics, sanitary ware, automobiles, parts, medical equipment, etc.; it is also suitable for small molds and precision copper processing.

Max. X-axis Travel :

600mmMax. Y-axis Travel :

450mmMax. Z-axis Travel :

300mmMax Workpieces Weight :

100KGApplication :

Precision Mold, Bathroom Products, Auto Parts, Semiconductor IndustryProcessing :

Drilling, TappingCNC Drilling Maching Center Characteristics

|

CNC Drilling Machine Center is a computer-controlled machining tool designed primarily for high-precision drilling operations, but it can also perform milling, tapping, reaming, and other machining tasks. |

Aviation Parts Processing Display

Drilling and Tapping Machining Center Parameters

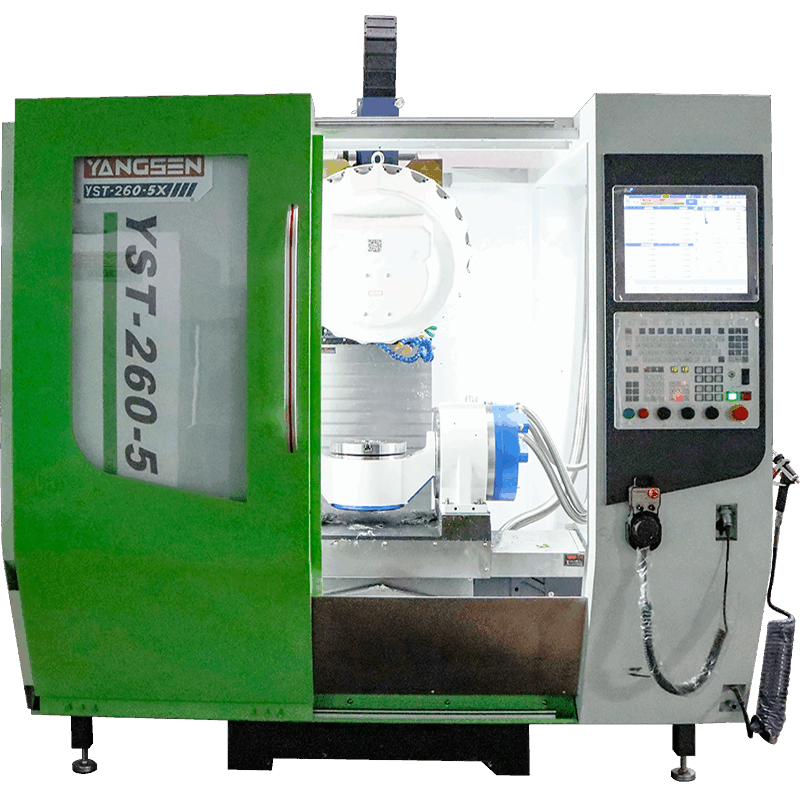

| Item | Spec | Units | YST-260-5X |

| Travel | X/Y/Z axis | mm | 600/450/300 |

| Spindle nose to table distance | mm | 50-350 | |

| Distance from spindle center to column track | mm | 520 | |

| track form | Linear guide | ||

| Worktable | Table size (L*W) | mm | Φ260 |

| The Max. load capacity of the worktable | kg | 100 | |

| Rotation diameter | mm | 400 | |

| Spindle | Spindle taper hole (model/installation size) | mm | B30 |

| Spindle RPM | rpm | 20000 | |

| Spindle drive mode | DDS | ||

| Feed | X/Y/Z axis rapid feed | m/min | 24/24/24 |

| Cutting feed | mm/min | 10000 | |

| Tool Changer | Tool change | UFO | |

| Handle Specifications | type | BT30 | |

| Tool Capacity | tools | 21 | |

| Max. Tool Diameter (Proximity Tool) | mm | 60 | |

| Max. Tool Diameter (Without Proximity Tool) | mm | 80 | |

| Max. Tool Length | mm | 200 | |

| Max. Tool Weight | kg | 3 | |

| Fastest tool change time | sec | 2S | |

| Motor | Spindle motor | kw | 3.7-5.5 |

| 3 axis servo motor | kw | 2.4/2.4/3.7 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy | positioning accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power requirement | power requirements | kva | 15 |

| Air source requirements | Kg/cm² | 6^8 | |

| Machine size | L*W*H | mm | 2300*2850*2750 |

| weight | t | 4.8 |

|

Safety Door Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Dual LED Work Light

LED 3 Color Warning Light

Spindle Oil Cooler

|

Spindle Nose Air Blow

Leweling Bolits and Pads

M30Auto Off

|

|

Optical Linear Scale

Chip Conveyor System

|

Tool Breakage Probe

Oil Skimmer

|

Oil Mist Collector

Workpiece& Tool Probe

|

CTS

Rotary Table

|

Tags :