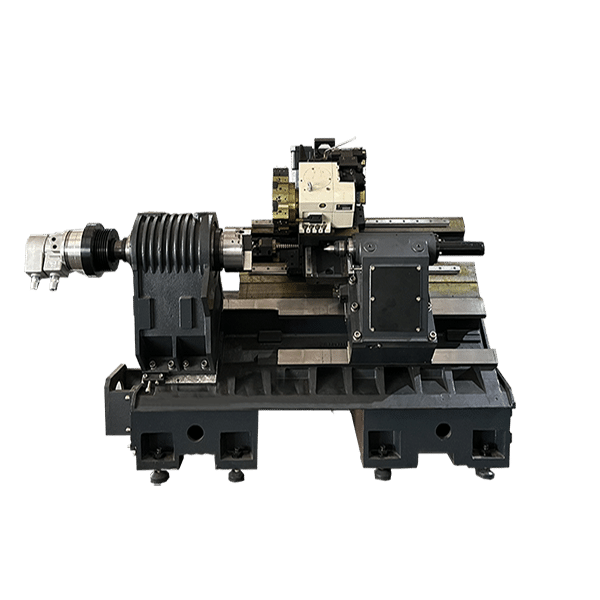

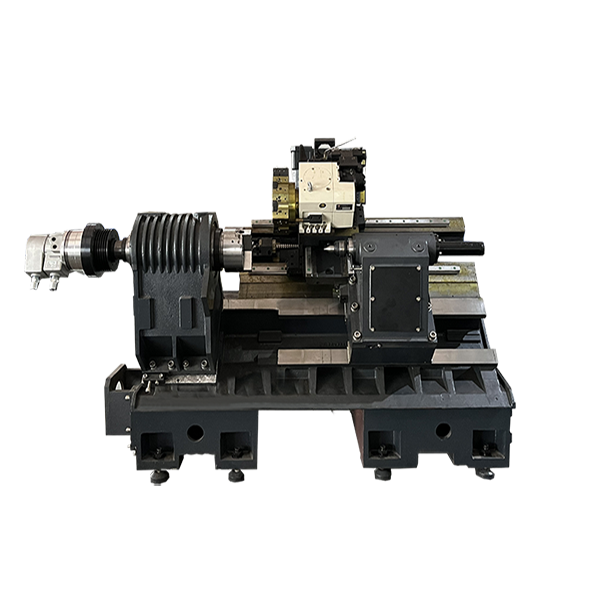

Horizontal Lathe Machine CNC Lathe YSC-580 adopts linear rolling guide imported from Taiwan to meet high-speed and high-efficiency requirements, reduce frictional resistance and temperature rise deformation, improve machining accuracy, and ensure long-term stability of cutting machining accuracy. The inclined bed CNC lathe adopts domestic or imported high-rigidity horizontal hydraulic servo turret tool holder, which has high positioning accuracy, fast tool change speed and small deformation in heavy cutting. The inclined bed CNC lathe adopts a 45-degree overall inclined bed structure, which can still maintain the stability of the machine tool precision during heavy cutting.

Max. X-axis Travel :

250mmMax. Z-axis Travel :

580mmMax Workpieces Weight :

4200KGApplication :

Precision Mold, Auto PartsProcessing :

Surface Milling, Drilling Holes, Tapping

Horizontal Lathe Machine YSC-580

|

1. The linear rolling guide rail imported from Taiwan is used to meet the high-speed and high-efficiency requirements, reduce frictional resistance and temperature rise deformation, improve machining accuracy, and ensure long-term stability of cutting machining accuracy. 2. The inclined bed CNC lathe adopts domestic or imported high-rigidity horizontal hydraulic servo turret tool holder, which has high positioning accuracy, fast tool change speed and small deformation in heavy cutting. 3. Standard configuration: stepless spindle speed regulation, hydraulic chuck, horizontal 8-station servo turret, closed protection. 4. Inclined bed CNC lathe adopts a 45-degree overall inclined bed structure, which can still maintain the stability of machine tool accuracy during heavy cutting. 5. The X and Z axis servo motors are directly connected to the precision ball screw through elastic couplings, with high precision. Both ends of the screw are fixed, which improves the support rigidity of the support seat, and minimizes the twisting and deformation of the screw caused by frequent high-speed positioning and heavy cutting. The bearings are Japanese NSK high-quality angular contact paired precision bearings, high speed and high precision. 6. The tailstock sliding guide rail structure ensures the high rigidity of the tailstock. The top is driven forward and backward by hydraulic pressure, the tailstock body is manually locked, and the overall movement is through the manual latch and dragged by the bed saddle. 7. The spindle box bearing adopts double-row cylindrical roller bearings. The design of the spindle box has the characteristics of low temperature rise, small thermal deformation and high precision, so that the relative stability of the spindle axis can be maintained when the spindle works for a long time. 8. The inclined bed CNC lathe adopts a full protection design, and the cooling box and chip conveyor are separated from the main machine to ensure that the accuracy of the machine tool is not affected by thermal cutting. 9. The electrical unit cabinet of the machine tool is well sealed, and has an air conditioner for the electrical cabinet to ensure that the CNC system works normally in the high temperature and high humidity environment of the machine tool. 10. The machine tool pays attention to the design of the edge technology, and the protection is reliable. When the powerful cutting and the coolant are sprayed with high pressure, there will be no iron filings or coolant splashing outside the machine tool. 11. In addition to program control, hydraulic chuck clamping, loosening and tailstock sleeve expansion and contraction can also be controlled by pedals, which is convenient and quick.

|

Vertical Lathe Parameters

| Description | Unit | Specification | ||

| Capacit | Bed swing over diameter | mm | ¢600 | |

| Max Turning diameter×length | mm | ¢500×580 | ||

| Spindle through hole diameter | mm | ¢65 | ||

| Max. bar working diameter | mm | ¢52 | ||

| Maximum supported mass | Kgf | 200 | ||

| spindle | Spindle speed(Max.) | rpm | 4500 | |

| Spindle nose | KSA | A2-6 | ||

| Chuck size | inch | 8″Hollow Chuck | ||

| Carring | Max. traverse | X-axis | mm | 250 |

| Z-axis | mm | 580 | ||

| Rapid traverse feed | X-axis | m/min | 30 | |

| Z-axis | m/min | 30 | ||

| Tooling | Max.gang No. of tool stations | ea | 8 | |

| Indexing time(one) | sec | 0.1 | ||

| OD tool height | mm | 25X25 | ||

| Boring bar diameter | mm | ¢32 | ||

| Tailstock | Tail center | Mohs5# | ||

| Tailstock traverse | mm | 500 | ||

| Tailstock sleeve top traverse | mm | 100 | ||

| Tailstock sleeve diameter | mm | ¢100 | ||

| Motors | Main spindle motor | kw | 15(15minute)/11(quota) | |

| Servo motor | X-axis | kw | 1.8 | |

| Z-axis | kw | 1.8 | ||

| Others | Electric power supply | KW | 20 | |

| Coolant tank capacity | L | 150 | ||

| Lubrication tank capacity | L | 1.8 | ||

| Machine height | mm | 2000 | ||

| Floor space | Length | mm | 2650 | |

| Width | mm | 1800 | ||

| Machine weight | kg | 4200 | ||

Tags :