Vertical machining centers offer exceptional versatility in cutting diverse materials while significantly improving productivity. By minimizing production cycle times and reducing machining costs, these machines enhance overall process profitability. Engineers have incorporated advanced design features to streamline operations, effectively decreasing downtime caused by frequent quality inspections. The CNC vertical machining center boasts an ergonomic design that optimizes operator comfort and working conditions for maximum efficiency.

Max. X-axis Travel :

1400mmMax. Y-axis Travel :

800mmMax. Z-axis Travel :

750mmMax Workpiece Length :

1500mmMax Workpieces Width :

800mmMax Workpieces Weight :

1500KGApplication :

Precision Mold, Auto PartsProcessing :

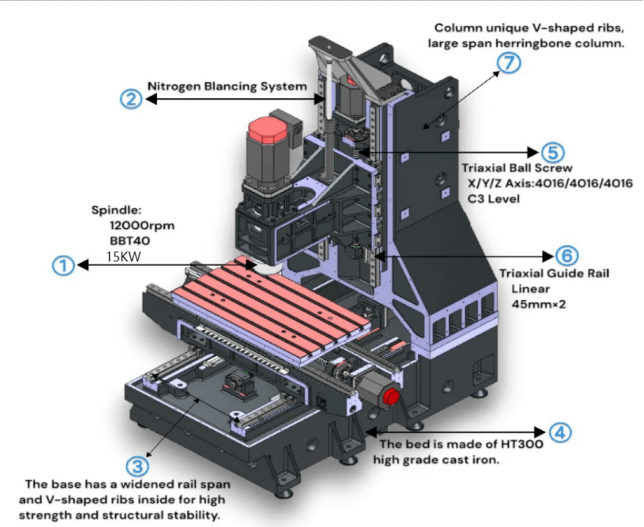

Surface Milling, Drilling Holes, TappingYSV-1482 Vertical Machining Machines Structural Characteristics

|

1. Using Taiwan frequency conversion tool magazine, the tool change time is shortened to 1.4S, which effectively improves the processing efficiency; 2. All three axes are equipped with large torque output as standard, enabling fast and accurate positioning; 3. The spindle motor is equipped with a 11-15KW high-torque generalized motor as standard, and the spindle torque is significantly improved compared with other brands of the same model, which is very suitable for heavy cutting; 4. The machine tool parts belong to the famous brand of famous factory, and the advanced configuration in the industry. |

Vertical Frame Machine Optomechanical Characteristics

|

1. The German Rexroth line rail is adopted, and the line rail width reaches 45mm; 2. The Y-axis has a super large span of 745mm; 3. Supported by 6 sliding seats on the X axis, strong rigidity ensures powerful cutting; 4. The three-axis adopts PMI outer diameter 40mm C3 grade screw, and the three-axis adopts NSK original bearing (3062), 3+2 mode, pre-tensioning treatment to prevent thermal displacement; 5. The outer diameter is 150mm and the high-rigidity BBT spindle is designed with ring spraying; 6. Adopt Taiwan original ultra-high-speed cutting cylinder, the cutting time can reach 0.28S; 7. The bed of the machine tool is made of precision HT300 high-grade cast iron. |

Vertical Machining Centers Parameters

| Item | Spec | Units | YSV-1482 |

| Travel | X/Y/Z axis | mm | 1400*800*750 |

| Spindle nose to table distance | mm | 150-900 | |

| Distance from spindle center to column track | mm | 880 | |

| track form | Linear guide | ||

| Worktable | Table size (L*W) | mm | 1500*800 |

| The Max. load capacity of the workbench | kg | 1500 | |

| T-slot | No/mm | 6-22*110 | |

| Spindle | Spindle taper hole (model/installation size) | mm | BBT40 |

| Spindle RPM | rpm | 8000 | |

| Spindle drive mode | Belt Type | ||

| Feed | X/Y/Z axis rapid feed | m/min | 24/24/24 |

| Cutting feed | mm/min | 10000 | |

| Tool Changer | Tool change | Side Amount frequency conversion | |

| Handle Specifications | type | BT40 | |

| Tool Capacity | tools | 24 | |

| Max. Tool Diameter (Proximity Tool) | mm | 80 | |

| Max. Tool Diameter (Without Proximity Tool) | mm | 120 | |

| Max. Tool Length | mm | 300 | |

| Max. Tool Weight | kg | 7 | |

| Fastest tool change time | sec | 1.4 | |

| Motor | Spindle motor | kw | βiIP 22/8000 |

| 3 axis servo motor | kw | βis22/3000/βis30/2000/βis30B/2000 | |

| Cutting water pump motor | m/h-m | 4月30日 | |

| Accuracy | positioning accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power requirement | power requirements | kva | 25 |

| Air source requirements | Kg/cm | 6~8 | |

| Machine size | L*W*H | mm | 4700*2950*2766 |

| weight | t | 10.5 |

|

Safety Door Automatic Lubricating System Fully Enclosure Guard Air Gun |

Rigid Tapping Heat Exchange for Electric Cabinet Spindle Coolant Nozzles Coolant Gun |

Dual LED Work Light LED 3 Color Warning Light Coolant Tank & Chip Tray Tool Box |

Spindle Nose Air Blow Leveling Bolts and Pads M30 Auto Off Maintenance and Operational Manual |

Options

|

Optical Linear Scale CTS Workpiece & Tool Probe |

Coolant Gun Tool Breakage System Chip Conveyor System |

Oil Mist Collector Oil Skimmer Rotary Table |

12000rpm DDS Spindle 15000rpm DDS Spindle HSK-63-18000 Built-In Moto |

Tags :