High-speed laser cutting machine is a high-precision CNC processing equipment widely used in modern industrial manufacturing. It integrates cutting, engraving and punching. It is highly favored for its high cutting accuracy, fast processing efficiency, intelligent operation and high degree of automation.

High-speed drilling and tapping machine, a kind of metal cutting CNC machining equipment commonly used in metal cutting machine tools, integrates cutting, drilling, and tapping. It is widely used with its advantages of accurate processing, fast processing, simple operation, and a high level of automation in drilling and tapping.

The style and function of the drilling and tapping machine are similar to that of the machining center (VMC). It can complete operations such as drilling, tapping, and milling. It is an indispensable production and processing equipment and the perfect solution for many parts processing plants and small shops.

1. Simple adjustment of high-precision tapping stroke.

2. The double safety clutch device can prevent the breakage of the wire-tapping.

3. The cooperation of multi-axis tapping machines can produce high-efficiency operation.

4. High-rigidity spindle: The advantage of the high-speed drilling and tapping machine is that the spindle milling force is large: the spindle speed is 10,000 rpm (20,000 rpm), and the power is 5.5/7.5KW, which can perform rigid machining actions in a short time. The main shaft adopts high-speed and high-precision bearings with low heat generation, with less vibration and noise. The spindle advance and retract tool is automatically and precisely matched according to the tooth distance, and it will not float up during work.

5. It can be matched with a 2-24-axis movable multi-axis, fixed multi-axis, and indexing plate to improve production capacity and save time and effort.

6. According to the needs and options of customers' parts processing, we can plan, design and manufacture semi-automatic and automatic drilling and tapping machine cutting machines.

7. Mature numerical control system (Fanuc, Siemens, and YS-S800): The high-speed drilling and tapping machine is equipped with a system with high performance, high stability, and high-speed data processing capability, which is more effective in the three-dimensional processing process.

| X/Y/Z axis | 800/450/410 |

| Spindle speed | 20000rpm |

| Positioning accuracy | ±0.005 |

| Repeat positioning accuracy | ±0.003 |

| Maximum load of worktable | 350kg |

First of all, the stroke of traditional drilling and tapping machines is generally within 800 × 400. Although it can be boring and milling, the milling load is weak, and it is generally used for drilling and tapping aluminum materials.

The high-speed drilling and tapping machine is continuously innovated on the basis of the traditional drilling and tapping machine. While developing the milling strength and the rigidity of the whole machine, the original processing efficiency of the drilling and tapping machine is maintained.

The turret-type tool magazine only needs 2 seconds to change the tool, which can complete high-precision tapping and take into account the efficiency. Secondly, the high-speed profile drilling and tapping machine can be developed and customized according to the needs of different users. Compared with the traditional drilling and tapping machine, it can meet the different processing needs of different processing plants.

1. Improve the working efficiency of processing and production, and reduce labor costs:

The high-speed drilling and tapping machine integrates the punching and tapping actions of the parts to be tapped, and the tapping and punching are directly performed on the punching machine simultaneously and improving the degree of automation and reducing the processing procedures.

2. Easy to install, easy to replace, easy to operate, and easy for novices to master:

The design of the high-speed drilling and tapping machine is sturdy and durable, small in size, and easy to install in different molds, and the tooth heads can be replaced with different specifications. Standard precision thread.

3. Improve production efficiency:

The use of high-speed drilling and tapping machines can save working time, with high tapping precision, short time, and high productivity.

4. Save labor:

The high-speed drilling and tapping machine combines the tapping and stamping of parts into one process, which is fully automated, thereby saving labor costs.

5. Reduce costs:

The use of high-speed drilling and tapping machines can reduce the probability of material feeding errors and the number of products in stock, thereby saving costs.

6. Energy saving:

After combining the stamping and tapping of the parts, the high-speed drilling and tapping machine is completely driven by mechanical transmission, thus saving the energy of the machine especially used for tapping

7. Multi-purpose One Machine:

Customized production can meet the general needs of the processing industry.

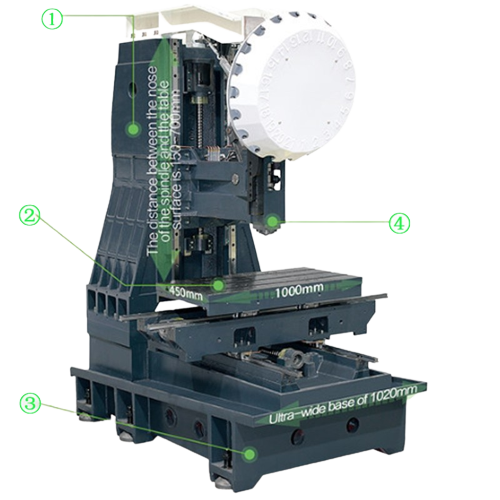

①. Higher Z-axis

The effective stroke of the Z axis is 410mm, the distance between the nose of the spindle and the table surface is 150-560mm, four axes can be installed without additional raiser blocks, and the rigidity of the machine tool is not affected.

②. Large Table

Table size:1000X450mm. The larger worktable allows bigger parts processing.

Optical linear scales

Optional Heidenhain, Fagor optical linear scales with an accuracy of under ±5um.

③.Stable Base

Shared V8 base, 1020mm span, high rigidity, high precision bed.

④.Powerful Motor

Standard 20000rpm BT30 high-speed motor, power 5.5kw; optional 12000rpm for large torque motor, power 7.5kw.

Fast tool change speed

Equipped with 21T servo tool magazine, tool change time is 1.8s; X/Y axis rapid traverse at 60m/min, Z axis rapid traverse at 48m/min.

Powerful spindle

YSV800 configuration BBT40 outer diameter 150mm with higher rigidity, and short nose spindle, five bearings, coolant nozzles.

Upgrade Configuration

German Rexroth roller linear guideway, Taiwan servo tool magazine, Taiwan spindle.

Beautiful appearance

European and American style sheet metal design, beautiful and practical

|

Safety Door

Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Dual LED Work Light

LED 3 Color Warning Light

Spindle Oil Cooler

|

Spindle Nose Air Blow

Leweling Bolits and Pads

M30 Auto Off

|

|

Optical Linear Scale

Chip Conveyor System

|

Tool Breakage Probe

Oil Skimmer

|

Oil Mist Collector

Workpiece& Tool Probe

|

CTS

Rotary Table

|

CNC Drilling and Tapping Centers is a high-precision, high-efficiency automated machine tool, widely used in industrial fields that require batch drilling, tapping, and chamfering.

|

|

YST Series:

| Model | YST-600 | YST-700 | YST-800 |

| Travel X/Y/Z Axis mm | 500/400/350 | 700/400/350 | 800/450/410 |

For more information, please click the above items.