Why Us:

Yangsen was born from a vision to provide you affordable and high-quality CNC equipment.

To give super high cost-effective price is our biggest advantage and also the goal and motivation of our continuous struggle in the past 20 years.

Compared with Taiwan and Japan CNC machine, our cost is only 50-70% while our CNC machine performance can reach 95-120%, and the its service life is more than 20 years. This stems from the strong background of Made-in-China, the perfect logistics system, and the perfect supply chain management system for more than 20 years.

Our Production Equipment

Vertical Machining Center Production

Vertical Machining Center Production 2nd

Double Column Machining Production

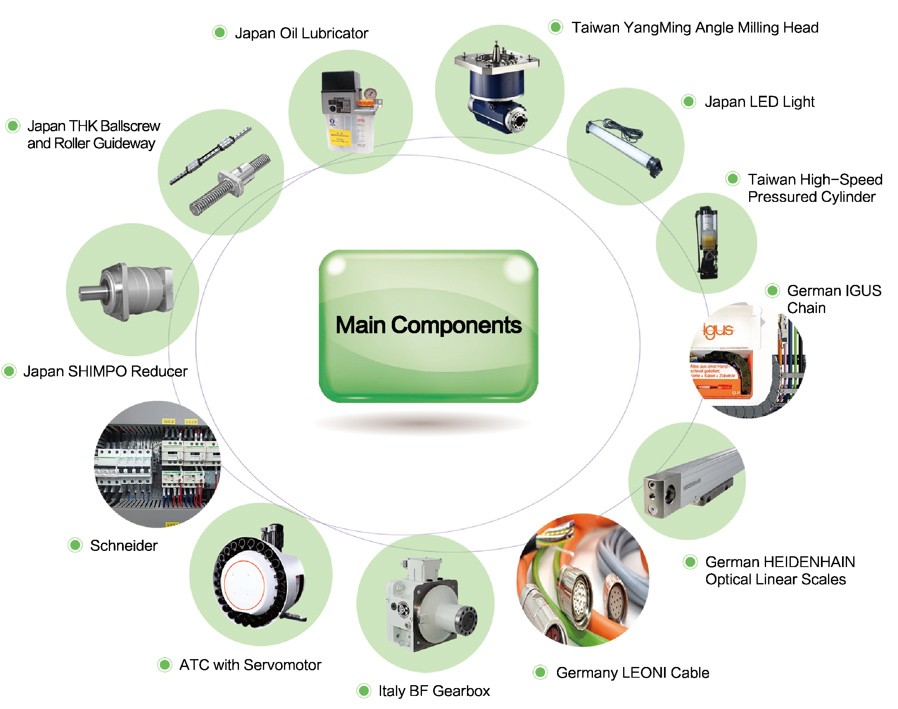

Key Spare Parts

In order to ensure that we provide you with 100% reliable products, the key spare parts we choose for you are all world-renowned manufacturers that have been strictly selected and passed our strict supply chain management system.

Yangsen CNC Machine Main Components

|

Japan THK Ball screw and Roller Guideway |

German HEIDENHAIN Optical Linear Scales |

| Japan SHIMPO Reducer | German lGUS Chain |

| Schneider | Taiwan High-Speed Pressured Cylinder |

| ATC with Servomotor | Japan LED Light |

| ltaly BF Gearbox | Taiwan YangMing Angle Milling Head |

| Germany LEONI Cable | Japan Oil Lubricator |

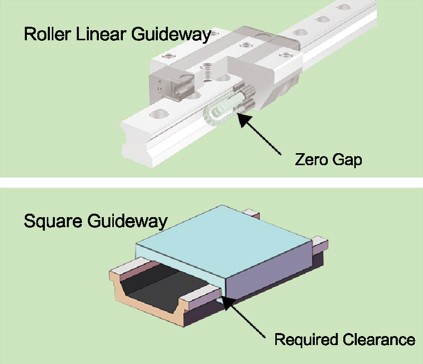

Recirculating roller linear guides has the significant advantage

The recirculating roller linear guide is pre-tensioned to ensure that there is no gap between the sliding surfaces.

This not only increases rigidity but also improves accuracy and stability. The friction coefficient of the linear guideway is low, so it can ensure repeat positioning accuracy and positioning accuracy during rapid movement.

Yangsen installs Japan THK roller linear guideway, whose motion medium of the roller linear guideway is in contact with line and surface rolling, and the motion medium of the ball linear guideway is in contact with the point surface rolling.

Therefore, the roller linear guideway has higher rigidity and greater accuracy than the ball linear guideway. The square guideway requires a gap between the sliding surfaces to move, and the friction coefficient is large, which is prone to adhesion and may cause machining errors.

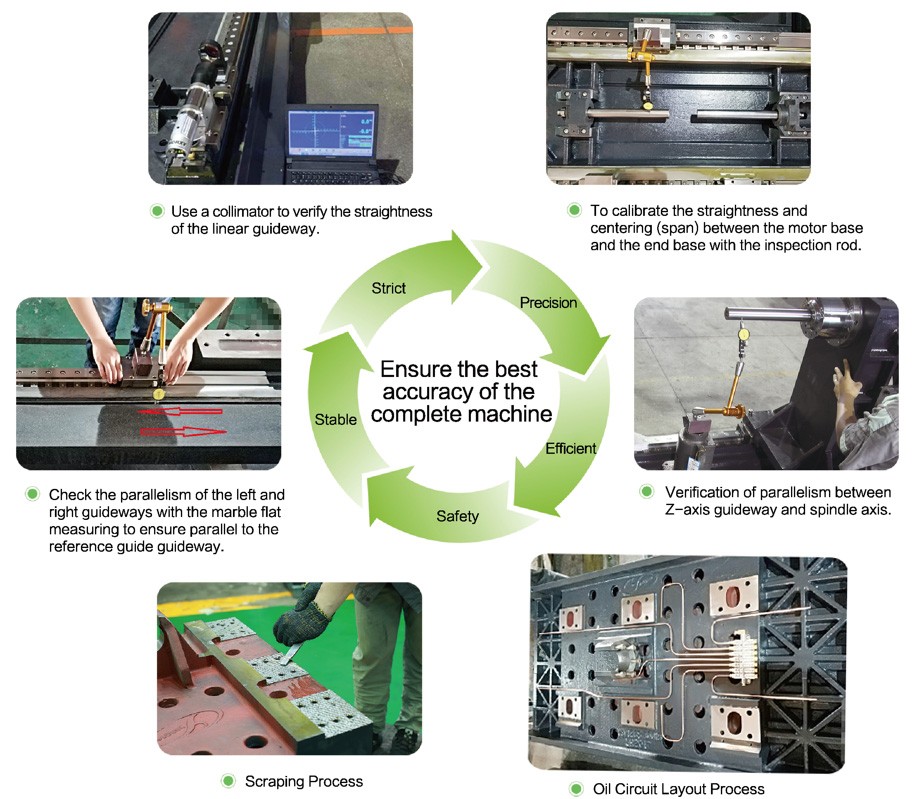

Muture and Stable Production Processing:

You can enjoy satisfying services provided by the production team with a total of more than 300 production line employees and 60% of them more than 10 years of experience, from Primary Machine Department, First Machine Assembling Department and Second Machine Assembling Department. Therefore, our technical processing is very stable, the production efficiency is always high, and the 100% yield rate before shipment. Such a complete production process helps you to minimize costs.

Production Processes:

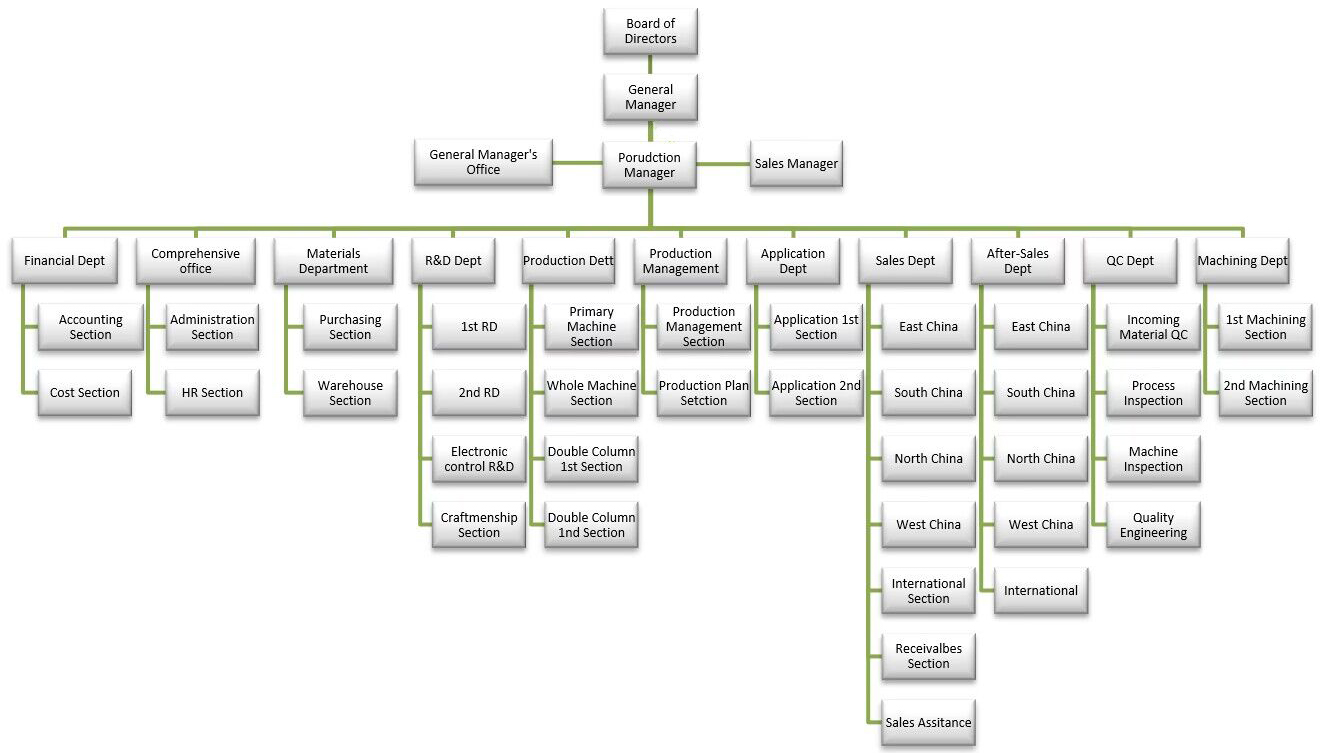

Organizational Structure of Yangsen

Who Serve You

Sales Department Yangsen

Strive for Perfection, Create High-Quality Products

You love Yangsen not only for his great price, but also for his excellent quality and his determination and attitude to keep improving.

Yangsen takes science and technology as the driving force. Focused unremittingly grasps product quality, creates a high-quality brand and casts a first-class corporate image. Adapting the production system to the ever-changing production requirements and to better satisfy our customers, the factory has always advocated lean production and created high-quality brands.

Certificate You may need:

ISO9001: 2015

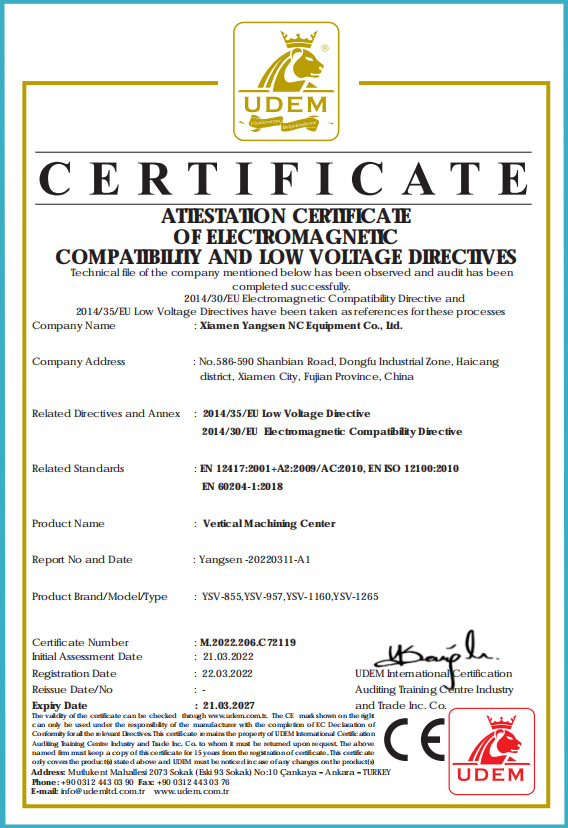

CE:

Utilizing Patent Certificate:

Another Certificate: