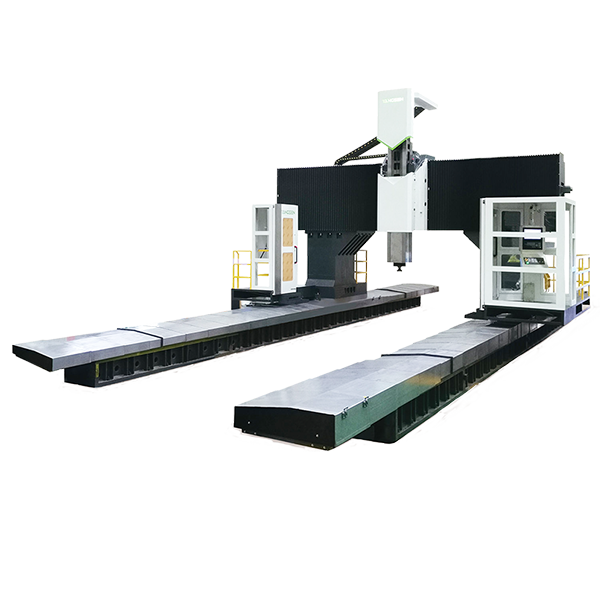

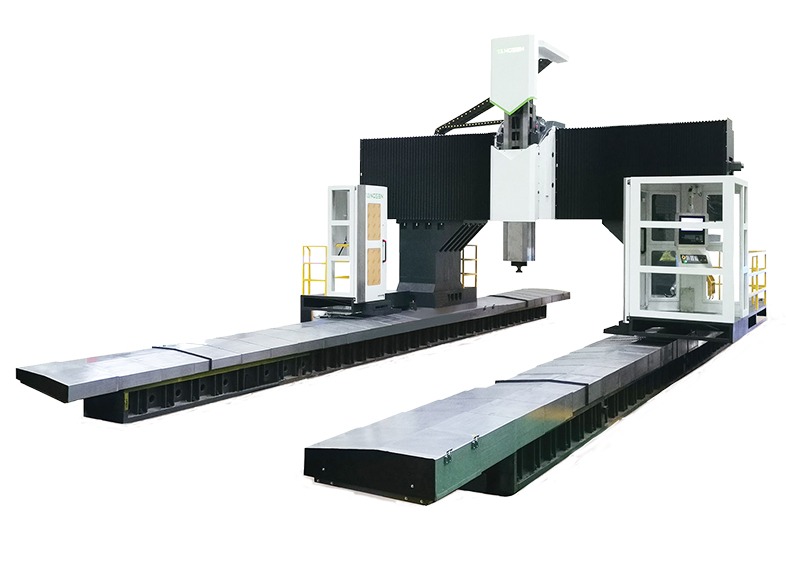

The Gantry Moving 5-Axis CNC Machine is a cutting-edge machine designed for precision and versatility in the woodworking and manufacturing industries.

Max. X-axis Travel :

32000mmMax. Y-axis Travel :

4200mmMax. Z-axis Travel :

800mmMax Workpiece Length :

32000mmMax Workpieces Width :

3500mmApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMD-32042 Gantry 5-Axis Machining Center

Double column machining center is a large machine tool. It is a large-scale machine tool specially designed for processing large parts. It is mainly used in heavy industry, automobiles, ships and other heavy industries. It mainly processes large and complex shapes of workpieces. Frames and certain parts on large machinery. In short, the Gantry Machining Center is a large machine tool designed to process large and complex parts, suitable for various industries, especially the large parts industry.

The overall layout of the machine tool is a synchronous moving gantry frame structure, the workbench is fixed, and the gantry frame moves back and forth; the left and right columns and the bed are distributed on both sides of the workbench. The gantry frame moves forward and backward on the X axis, the encircling ram moves vertically on the slide plate in the Z direction, and the slide plate and the ram move horizontally on the beam in the Y direction.

The Main Structure of YSMD-32042-5A

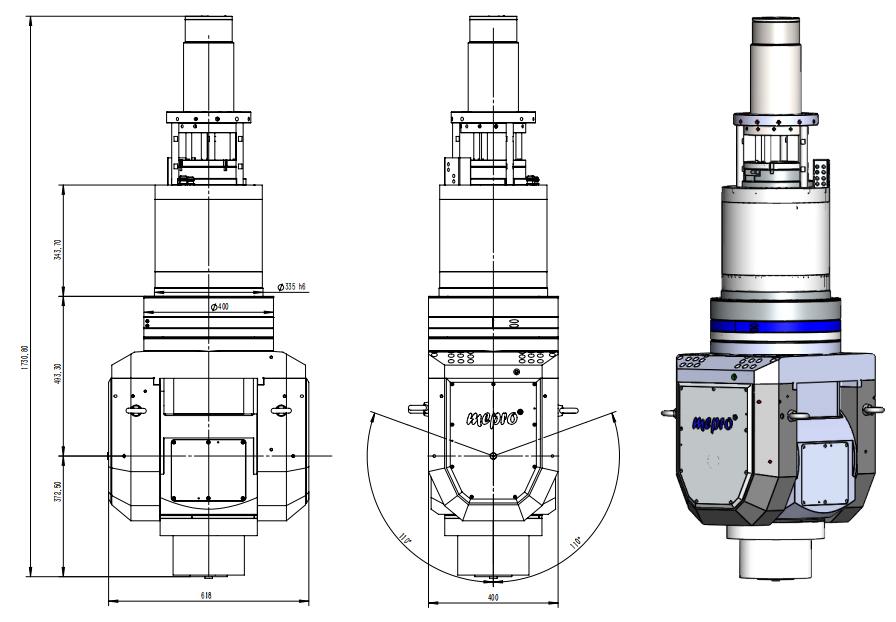

The spindle adopts HSKA100 high-speed electric spindle. The spindle has a water-cooled internal cooling method to reduce the thermal deformation of the spindle, improve the stability of the spindle precision and the machining accuracy of the machine tool. The machine tool has the functions of spindle orientation and rigid tapping. The headstock parts adopt double nitrogen liquid balance cylinder mechanism to ensure the stability of the headstock movement.

Five-axis linkage double pendulum milling head: A/C mechanical axis + electric spindle, fork type integrated structure, with high rigidity characteristics, A/C axis adopts unique anti-backlash structure transmission.

Main Technical Parameters of Gantry CNC Machining Center

| Subject | Specification | unit | YSMD-32042-5A |

| Travel | X/Y/Z axis | mm | 32000х4200х800 |

| Spindle nose to the worktable surface | mm | 200-1000 (including head) | |

| Gantry width | mm | 4200 | |

| Worktable | worktable(L*W) | mm | 32000х3500 |

| Worktable max load | t | 10 | |

| T SLOT | mm | 36*200 | |

| Spindle | Spindle type | mm | HSK 100А |

| Spindle speed | rpm | 10000 | |

| Spindle delivery type | Electric spindle | ||

| Spindle power (S1/S6), not less than | KBT | 54 | |

| Moment (S1/S6), not less than | Нm | 200 | |

| Feed rate | Feed rate ( X/Y/Z ) | m/min | 2008-8-8 |

| The max cutting feed rate | mm/min | 6000 | |

| ATC(optional) | Tool change method | side mount | |

| Knife handle specifications | type | HSKA100 | |

| Tool capacity | tools | 30 | |

| Maximum tool diameter (temporary tool) | mm | 112 | |

| Maximum tool diameter (without critical tool) | mm | 200 | |

| Maximum tool length | mm | 350 | |

| Maximum tool weight | kg | 18 | |

| Fastest tool change time | sec | 4.9 | |

| Motor | Spindle motor | kw | 54 |

| x/y/z axis motor | kw | 5.2*4/5.2/5.2 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy | Positioning | mm | 0.035/2000,0.035,0.02 |

| Repeatability | mm | 0.03/2000,0.025,0.015 | |

| Power requirement | Power requirement | kva | 60 |

| Air pressure requirement | Kg/cm² | 6 | |

| others | L*W*H | mm | 45600*8130*5920 |

Tags :