Understanding the difference between cutting speed and spindle speed is crucial for achieving stable machining, a good surface finish, and extended tool life. Many machinists confuse these two concepts, but they are distinct. Cutting speed describes how fast the cutting edge moves across the material, while spindle speed (RPM) refers to how fast the tool rotates.

In CNC milling and turning, choosing the right cutting speed and spindle speed can reduce heat, prevent tool wear, and improve machining efficiency. This guide explains cutting speed vs spindle speed, how to calculate them, and how they work together for different materials such as steel, stainless steel, and aluminum.

Cutting speed refers to the linear speed at which the cutting edge of the tool moves across the surface of the workpiece. It is usually measured in meters per minute (m/min) or surface feet per minute (SFM). Unlike spindle speed, which describes how fast the tool rotates, cutting speed focuses on the actual contact speed between the tool and the material.

Selecting the correct cutting speed is critical because it directly affects tool life, heat generation, chip formation, and overall machining stability. Higher cutting speeds produce more heat and may reduce tool life, while speeds that are too low can cause poor chip evacuation and a built-up edge.

Cutting speed also varies depending on the material being machined. For example, aluminum allows very high cutting speeds, while stainless steel requires significantly lower speeds due to its hardness and heat sensitivity. Modern carbide tools generally support higher cutting speeds than high-speed steel (HSS) tools.

In CNC machining, cutting speed serves as the foundation for calculating spindle speed (RPM) and ensuring efficient milling, turning, and drilling operations.

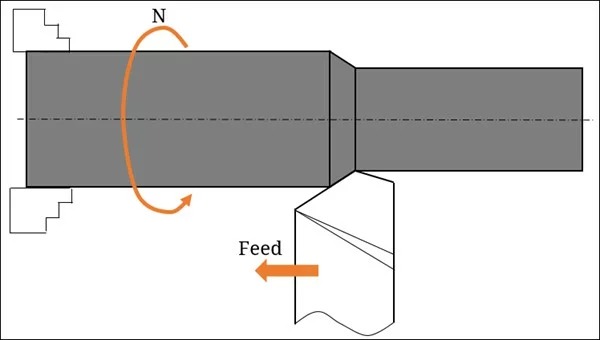

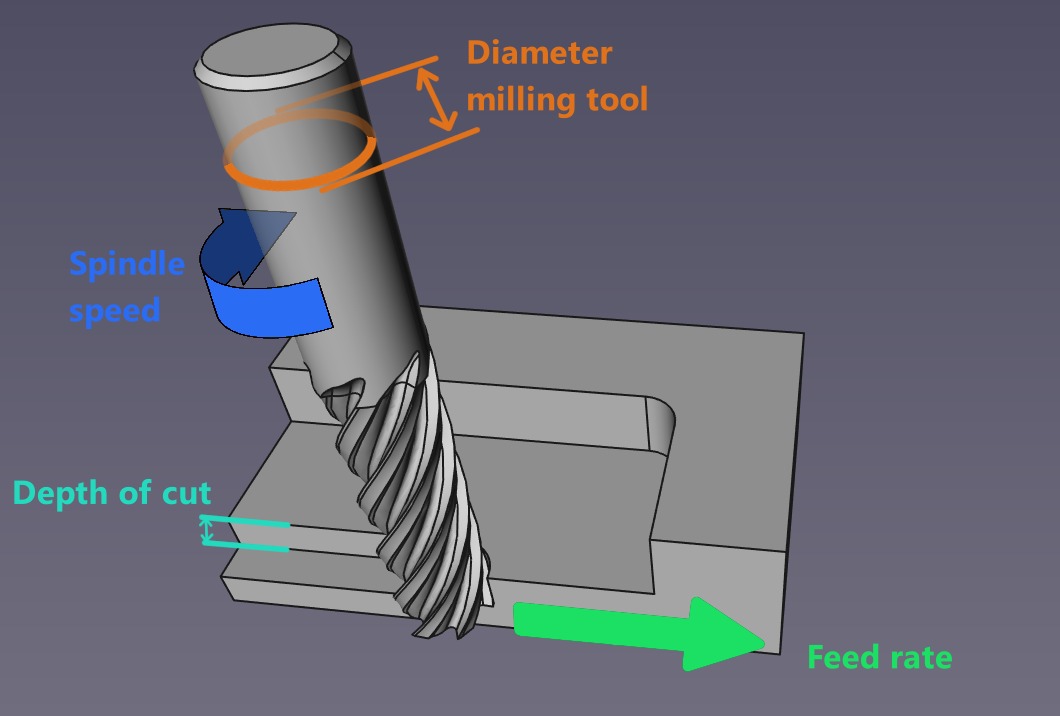

Spindle speed refers to the rotational speed of the tool or the workpiece, measured in revolutions per minute (RPM). It tells you how many times the tool rotates in one minute. While cutting speed focuses on the tool’s linear movement over the material, spindle speed describes the tool’s rotation itself.

Spindle speed is directly influenced by the diameter of the tool. Smaller tools require higher RPM to reach the same cutting speed, while larger tools need lower RPM to avoid excessive heat and vibration. This is why changing the tool size always requires recalculating the spindle speed.

Choosing the correct spindle speed is essential for preventing chatter, tool breakage, poor surface finish, and excessive wear. Too much RPM can overheat the cutting edge, while too little RPM may cause rubbing instead of cutting.

In CNC milling and turning, spindle speed works together with cutting speed and feed rate to ensure stable machining performance. It is a key parameter in toolpath programming, especially when cutting different materials like steel, aluminum, and stainless steel.

Although cutting speed and spindle speed are related, they describe two completely different aspects of machining:

Cutting speed is linear; spindle speed is rotational.

Cutting speed measures how fast the cutting edge moves across the material surface.

Spindle speed measures how fast the tool rotates in RPM.

Cutting speed stays constant; spindle speed changes with tool diameter.

Machinists choose a cutting speed based on the material (steel, stainless steel, aluminum).

Spindle speed must be calculated according to the tool diameter to match the cutting speed.

Cutting speed affects heat and tool wear.

High cutting speed increases heat and reduces tool life.

Low cutting speed can cause rubbing and poor chip formation.

Spindle speed affects stability and surface finish.

Too many RPMs can cause vibration or chatter.

Too little RPM leads to rough surfaces and inefficient cutting.

Cutting speed determines RPM.

Cutting speed is the starting point.

Spindle speed (RPM) is calculated from the cutting speed formula.

Understanding these differences helps ensure better machining performance, longer tool life, and more accurate programming in CNC operations.

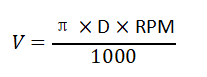

Accurate calculation of cutting speed and spindle speed is essential for efficient and safe CNC machining. Here’s how it works:

Cutting speed (V) is usually measured in meters per minute (m/min) or surface feet per minute (SFM).

The formula to calculate cutting speed is:

V = cutting speed

D = tool diameter

RPM = spindle speed

This shows that cutting speed depends on both spindle speed and tool diameter.

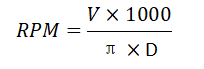

If you know the desired cutting speed, the spindle speed can be calculated:

Adjust D to match the tool diameter in millimeters.

For inches, convert SFM to the appropriate unit.

Small-diameter end mill: high RPM required to reach the recommended cutting speed.

Large-diameter milling cutter: lower RPM needed to maintain the same cutting speed.

Aluminum allows higher cutting speeds; stainless steel requires lower speeds to avoid overheating.

Always check the tool manufacturer's recommendations for cutting speed.

Use CAM software or calculators to ensure correct RPM.

Combine the correct spindle speed with the appropriate feed rate for optimal machining.

By understanding these formulas, you can set the correct cutting speed and spindle speed to maximize tool life, reduce heat, and achieve better surface finish.

Tool diameter plays a crucial role in determining spindle speed for a given cutting speed. Understanding this relationship helps prevent tool damage and ensures consistent machining performance.

Small-diameter tools must rotate faster to maintain the same cutting speed.

Example: A 10 mm end mill requires much higher RPM than a 50 mm cutter at the same cutting speed.

High RPM for small tools increases the risk of vibration, so balancing spindle speed and feed rate is important.

Large-diameter tools cover more surface per revolution.

Lower RPM prevents excessive heat and reduces tool wear.

Using the wrong RPM for large tools can lead to poor surface finish or tool breakage.

End mills, drills, and boring tools each require specific spindle speed adjustments.

Always recalculate RPM when changing tool size.

Use CAM software or spindle calculators to ensure accuracy.

Proper cutting speed and spindle speed are critical for tool longevity and machining efficiency. Incorrect settings can quickly lead to tool damage or poor-quality parts.

Too high: Generates excessive heat, causing rapid tool wear or edge chipping.

Too low: Leads to rubbing rather than cutting, creating built-up edge (BUE) and poor surface finish.

Optimal cutting speed balances heat generation, chip formation, and tool life.

Too high RPM: Can cause vibration, chatter, and premature tool failure.

Too low RPM: Reduces cutting efficiency and may damage the material surface.

Proper RPM ensures stable cutting and accurate surface finishes.

Cutting speed and spindle speed work together: cutting speed sets the target, and spindle speed adjusts based on tool diameter.

The correct combination reduces wear, improves surface finish, and maximizes material removal rate (MRR).

Steel and stainless steel require lower cutting speeds to prevent overheating.

Aluminum and softer metals allow higher speeds and higher RPM.

Carbide tools support higher cutting speeds compared to HSS tools.

Different materials require different cutting speeds and spindle speeds to achieve optimal machining performance. Selecting the correct parameters ensures longer tool life, better surface finish, and higher efficiency.

Steel

Cutting speed: 50–120 m/min (depending on hardness and alloy).

Use a moderate RPM based on tool diameter.

Lower speeds help prevent heat buildup and tool wear.

Stainless Steel

Cutting speed: 30–80 m/min (harder materials require slower cutting).

Spindle speed should be reduced to avoid vibration and edge chipping.

Coolant is highly recommended to control temperature.

Aluminum

Cutting speed: 200–600 m/min (soft, easy-to-machine metal).

High spindle speeds allow efficient material removal.

Adjust feed rate to prevent chatter with small-diameter tools.

Brass, Copper, Plastics

Brass: moderate cutting speeds, smooth chip flow.

Copper: lower speed to prevent work hardening.

Plastics: high speed, low feed, and careful chip evacuation.

Tool Material Considerations

High-Speed Steel (HSS): Lower cutting speeds, longer contact time.

Carbide Tools: Support higher speeds and higher RPM for faster machining.

Always follow the manufacturer’s recommended speeds for the tool type.

Common mistakes when setting cutting speed and spindle speed usually come from treating all materials the same. Each material requires its own recommended cutting speed, so using one universal value quickly leads to rapid tool wear and poor surface finish. Another frequent error is ignoring tool diameter—small tools must run at higher RPM while larger tools require lower RPM. Many operators also set the spindle speed too high, causing heat, burning, and chip welding, while too low an RPM leads to rubbing instead of cutting. Choosing a cutting speed that doesn’t match the tool material is also a common issue, since HSS and carbide require different parameters. Finally, insufficient coolant, especially when machining stainless steel or high-temperature alloys, increases heat and shortens tool life significantly.

1. What is the difference between cutting speed and spindle speed?

Cutting speed refers to how fast the cutting edge moves across the material surface (measured in m/min or ft/min). Spindle speed is the rotational speed of the spindle in RPM. Cutting speed determines the correct RPM based on tool diameter.

2. Why is cutting speed important in CNC machining?

Because it controls heat, chip formation, and tool wear. The right cutting speed improves tool life, surface finish, and overall machining efficiency.

3. Can I use the same cutting speed for carbide and HSS tools?

No. Carbide tools can run at much higher speeds because they tolerate heat better. HSS tools need lower speeds to prevent burning.

4. What happens if my spindle speed is too high?

You may see overheating, blue chips, tool burning, or premature tool failure.

5. What happens if my spindle speed is too low?

The tool rubs instead of cutting, causing poor surface finish, excessive heat, and inefficient machining.

6. Do coolant and lubrication affect the recommended speed?

Yes. With adequate coolant, you can often run slightly higher speeds and achieve better tool life, especially when cutting stainless steel or superalloys.

Understanding the difference between cutting speed and spindle speed is essential for achieving stable, efficient, and cost-effective machining. When these two parameters are set correctly, you get smoother finishes, longer tool life, and higher productivity—exactly what every CNC shop needs. Always start with recommended speed charts, apply the proper formulas, and fine-tune based on your actual cutting conditions.

If you’re looking for reliable CNC machines that deliver consistent performance with accurate speed control, YANGSEN offers machining centers designed for precision, durability, and demanding industrial applications. Contact our team anytime for technical support or to get a quote tailored to your machining needs.