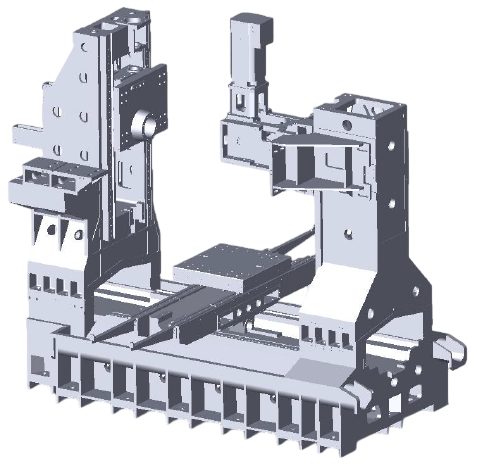

A horizontal machining center is a CNC machine tool with a spindle axis parallel to the worktable. This type of machine tool is mainly suitable for processing box-type parts. Its spindle is in a horizontal state and usually has a square worktable that can perform indexing and rotary motion. It is very suitable for multi-process processing such as milling, drilling, boring, reaming, tapping, two-dimensional and three-dimensional curved surfaces of multiple working surfaces of parts.

Max. X-axis Travel :

1100mmMax. Y-axis Travel :

700mm/500mmMax. Z-axis Travel :

650mmMax Workpiece Length :

630mmMax Workpieces Width :

630mmMax Workpieces Weight :

630kgApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingYSVH-1163 Horizontal Machining Center Features

|

Adopts the latest Japanese M80A vertical and horizontal machine board system. The machining program is common to both vertical and horizontal The axis exchange command of any axis exchange function can complete the switching of axis names, without changing the machining program or CAM software post-processing High-speed and high-precision compatibility Both vertical and horizontal modes support high-speed and high-precision mode to ensure machining accuracy Easy switching between vertical and horizontal modes Quickly switch modes through commands, convenient for customers to use Vertical and horizontal functions are interoperable Vertical and horizontal modes can achieve the same functions to ensure mutual relevance |

Features of YSVH-1163 optical machine:

|

1. The machine is equipped with a spiral chip conveyor interface and a cutting flushing device to automatically discharge the chips in time to avoid the thermal impact of the chips on the machine tool and ensure the high precision of the machine tool processing; 2. The casting wood mold adopts aluminum-wood combination, resin sand casting, and workbench HT300.

3. The standard Taiwan Xuyang CNC rotary table adopts high-rigidity nickel-silver alloy copper turbine, which is wear-resistant and durable, and has high segmentation stability; double strong locking device, super large locking surface, heavy cutting resistance; three high-precision clutch gears are used for positioning, and the repeated positioning accuracy reaches 5″. |

|

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

|

Cutting depth 7mm |

|

Cutter diameter Ø82 |

|

Tapping M36 |

|

|

Cutter |

Ø120mm*5T |

Cutter |

Ø82mm*2T |

Cutter |

M36*3P |

|

Spindle speed |

420rpm |

Spindle speed |

500rpm |

Spindle speed |

120rpm |

|

Feed |

F500 |

Feed |

F100 |

Feed |

F480 |

|

Width |

100mm |

Width |

82mm |

Width |

36mm |

YSVH-1163Horizontal Machining Cemter Parameters

| Subject | Specifications | Units | Vertical type | Horizontal type |

| Travel |

Vertical and horizontal X-axis travel (left and right of worktable) | mm | 1100 | |

| Vertical Y-axis travel (before and after the vertical spindle center) | mm | 700 | ||

| Horizontal Y-axis travel (spindle box up and down) | mm | 500 | ||

| Horizontal Z-axis travel (spindle box up and down) | mm | 650 | ||

| Distance from the nose of the vertical and horizontal spindle to the turntable surface | mm | 120-770 | 120-620 | |

| Distance from the nose of the horizontal spindle to the center of the turntable | mm | 170-870 | ||

| Vertical guide surface to the center of the spindle | mm | 702 | ||

| Horizontal guide surface to the nose of the spindle | mm | 305 | ||

Worktable |

Turret worktable area | mm | 630*630 | |

| Rotation method | Oil pressure | |||

| Equal fraction | deg | 1*360° | ||

| Maximum rotation diameter of the workpiece | mm | 1300 | ||

| Maximum load-bearing capacity | KG | 600 | ||

Spindle |

Spindle taper hole (model/installation size) | mm | BBT40 | |

| Spindle speed | rpm | 10000 | ||

| Spindle transmission method | Belt type | |||

| Feed |

X/Y/ZN1-axis rapid feed | m/min | 36/36/30/30 | |

| Maximum cutting feed | mm/min | 10000 | ||

Tool Changer |

Tool change method | Side-mounted/horizontal | ||

| Tool holder specifications | type | BT40 | ||

| Tool capacity | tools | 24 | ||

| Maximum tool diameter (with tool) | mm | 78 | ||

| Maximum tool diameter (without tool) | mm | 120 | ||

| Maximum tool length | mm | 300 | ||

| Maximum tool weight | kg | 7 | ||

| Fastest tool change time | sec | 2.2 | ||

| Motor | Spindle motor | kw |

Vertical SJ-DG7.5/120 Horizontal SJ-DG7.5/120 |

|

| Servo motors for each axis | kw | HG303/HG303HG303B/HG303B/HG204 | ||

| Cutting water pump motor | m/h-m | 4-60 | ||

Accuracy |

Positioning accuracy | mm | ±0.005 | |

| Repeat positioning accuracy | mm | ±0.003 | ||

Power requirements |

Electricity requirements | 40 | ||

| Air source requirements |

6~8 |

|||

Size |

Length*width*height | 3850*3200*3300 | ||

| Weight | 10.8 | |||

|

Arm Type Tool Changer

Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Daul LED Work Light

LED 3 Color Warning Light

M30 Auto Off

|

Spindle Nose Air Blow

Leveling Bolts and Pads

|

|

Optical Linear Scale

CTS

|

Tool Breakage System

Chain Type Chip Conveyor System

|

Oil Mist Collector

Oil Skimmer

|

Rotary Table

Workpiece &Tool Probe

|

Tags :