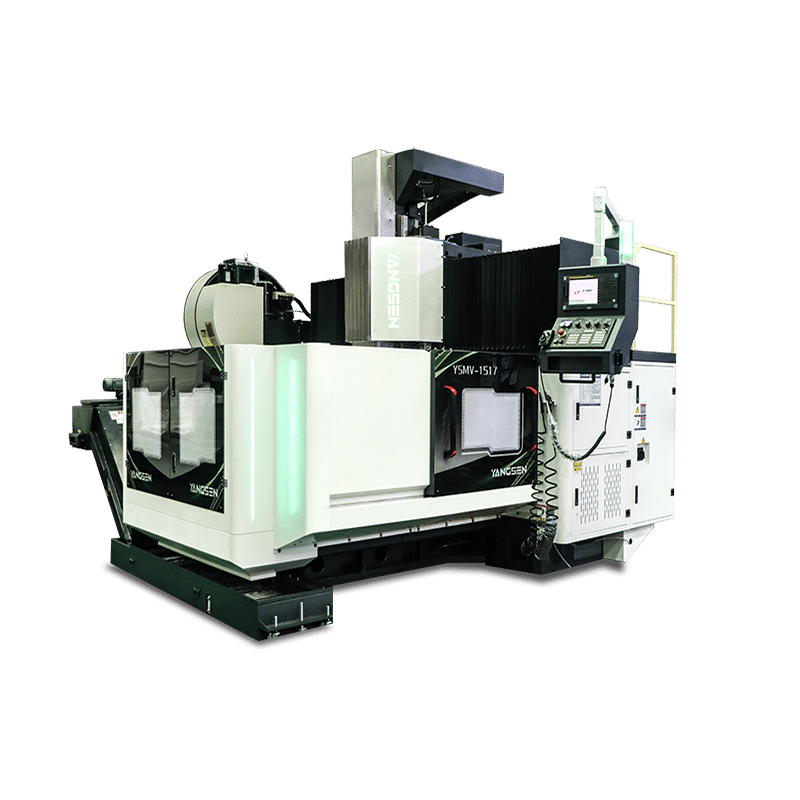

The overall layout of Gantry Double Column Machining is a fixed-beam beam structure, with the workbench moving forward and backward; the left and right columns and the bed are distributed on both sides of the workbench. The gantry worktable moves forward and backward on the X axis, the ram moves vertically on the skateboard in the Z direction, and the skateboard and the ram move horizontally on the beam in the Y direction.

Max. X-axis Travel :

1500mmMax. Y-axis Travel :

1700mmMax. Z-axis Travel :

800mmMax Workpiece Length :

1500mmMax Workpieces Width :

1400mmMax Workpieces Weight :

6TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMV-1517 Gantry CNC Machine Features

|

|

The overall layout of the machine tool is a fixed-beam beam structure, and the worktable moves forward and backward; the left and right columns and the bed are distributed on both sides of the workbench. The gantry table moves forward and backward in the X axis, the ram moves vertically in the Z direction on the slide plate, and the slide plate and the ram move horizontally in the Y direction on the beam. Workbench moves vertically (X Axis) The saddle moves along the beam (Y Axis) Axial movement of the ram (Z Axis) The picture is for reference only, the actual product shall prevail |

The main shaft motor is driven to the main shaft end through the main shaft coupling. The motor reduces the thermal deformation of the spindle through the constant temperature cooling method, which improves the stability of the spindle precision and the machining accuracy of the machine tool. The spindle group adopts Taiwan BBT50 high-rigidity spindle, ring-sprayed design, with high precision and high performance. The main shaft grabs the tool by the butterfly spring on the main shaft acting on the pull stud of the tool handle through the four-petal claw broach mechanism with the tension force. The machine tool has the functions of spindle orientation and rigid tapping.The main shaft can be optionally equipped with a BF gearbox to achieve high and low speed changes through automatic shifting, and stepless speed regulation within each

YSMV-1517 Gantry Machining Center Parameters

| Items | Specifications | Units | YSM-1517 |

| Travel | X/Y/Z Axis | mm | 1500*1700*1000 |

| Distance From Spindle Nose to Worktable | mm | 150-1150 | |

| Gantry Width | mm | 1700 | |

| Worktable | Table Size (L*W) | mm | 1500*1400 |

| The Maximum Load Capacity of The Workbench | t | 2 | |

| T-Slot | mm | 7-22*200 | |

| Spindle | Spindle, Taper Hole (Model/Installation Size) | mm | BBT50 |

| Spindle Speed | rpm | 6000 | |

| Spindle Max Speed | rpm | 4500 | |

| Spindle Drive Mode | Belt Type | ||

| Feed | X/Y/Z Axis Rapid Feed | m/min | 2012-12-10 |

| Cutting Feed | mm/min | 8000 | |

| Tool changing device (optional) | Tool Change Method | 侧挂式 | |

| Handle Specifications | type | BT50 | |

| Tool Capacity | tools | 24 | |

| Maximum Tool Diameter (Adjacent Tool) | mm | φ112 | |

| Maximum Tool Diameter (Without Adjacent Tool) | mm | φ200 | |

| Max Tool Length | mm | 300 | |

| Max Tool Weight | kg | 18 | |

| Fastest Tool Change Time | sec | 4.9 | |

| Motor | Spindle Motor | kw | βiIP30/8000 |

| Three-Axis Servo Motor | kw | bis40/2000/bis40/2000/bis40B/2000 | |

| Cutting Water Pump Motor | m/h-m | 4-60 | |

| Tolerance(GB/T 19362.2—2017) | Positioning Accuracy | mm | 0.02/0.02/0.018 |

| Repeatability | mm | 0.016/0.014/0.008 | |

| Power Requirement | Power Requirements | kva | 45 |

| Air Source Requirements | Kg/cm | 6^8 | |

| Machine Size | Length*Width*Height | mm | 4126*4712*3941 |

| Weight | t | 16 |

Standard Accessories

|

Rigid Tapping Automatic Lubricating System Semi-Enclosed Guard |

Dual LED Work Light Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Spindle Nose Air Blow LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

M30 Auto Off Leveling Bolts and Pads |

Options

|

Optical Linear Scale CTS 40T ATC |

Tool Breakage System Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer 90° Manual Milling Head |

Air Conditioner Auto Parts Probe Measuring System 90° Auto Milling Head with AHC |

Tags :