Vertical CNC machining centers perform reliably and efficiently in manufacturing and production sectors of metal working across automotive, mechanical engineering, and medical technologies. From the universally applicable vertical versions to the 5 axis vertical machining centers, every machine has automatic tool changers and state-of-the-art CNC control technology. From portal milling machines with large traverse paths to compact machines with small space requirements, find a right solution at KNUTH Machine Tools.

Max. X-axis Travel :

1300mmMax. Y-axis Travel :

750mmMax. Z-axis Travel :

600mmMax Workpiece Length :

1360mmMax Workpieces Width :

700mmMax Workpieces Weight :

1500KGApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingVertical Machining Structural Characteristics

|

|

Vertical Frame Machine Structural Characteristics

|

Japan NBK coupling/Japan NSK bearing Taiwan PMI outer diameter 50mm C3 grade ballscrew 1. Ballscrew pre-tensioning treatment to prevent hot stretch. 2. Box-way design at the rear of the spindle head, triangular structure, Z-axis 6-slider support, super rigid. 3. Install Taiwan Φ155 high rigidity BBT50, 6000rpm, 6 bearings, coolant nozzles design. 4. Three-axis travel X: 1300/Y: 750/Z: 680 Reserved for optical linear scales installation. 5. The Y-axis is supported by 4 German Rexroth ball linear guideway for maximum rigidity and accuracy. 6. Worktable: 1360*700 mm 7. BF Gearbox. Optional Italian BF gearbox, super cutting ability, high and low gear functions, stepless gear change. The bad is made of precision HT300 high grade cast iron |

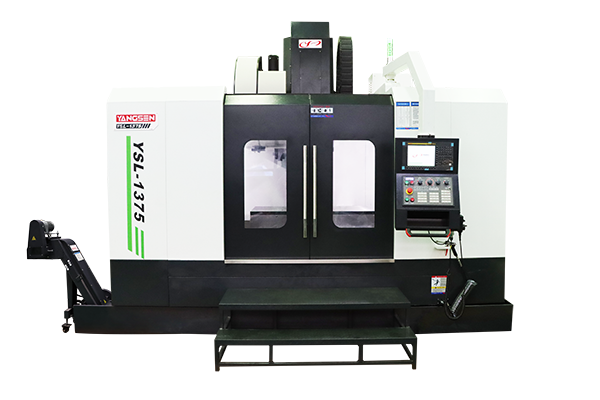

| Model | YSL-1375 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1300x750x600 |

| Spindle Nose to Worktable | mm | 70-670 | |

| Spindle Center to Column | mm | 785 | |

| Three-Axis Guideway | / | X/Y Roller Linear Guideway & Z Box Way | |

| Worktable | Worktable Size (L*W) | mm | 1360x700 |

| Maximum Table Load | kg | 1500 | |

| T-Slot | mm | 5-18x122 | |

| Spindle | Spindle taper | type | BBT-50 |

| Spindle speed | rpm | 6000 | |

| Spindle Drive Type | / | Belt | |

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 20/20/10 |

| Cutting Feedrate (X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | / | ARM Type |

| Type of Tool Shank | type | BT50 | |

| Tool Storage Capacity | Piece | 24 | |

| Max. Tool Diameter (Adjacent) | mm | 105 | |

| Max. Tool Diameter (Empty) | mm | 200 | |

| Max. Tool Length | mm | 350 | |

| Max. Tool Weight | kg | 15 | |

| Tool Change Time | sec | 4.9 | |

| Motor | Spindle Motor | kw | 15 |

| Three-Axis Seiw Motor | kw | 3.0/3.0/4.5 | |

| Accuracy | Accuracy | mm | ±0.005/300 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 25 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 3559x2965x2686 |

| Gross Weight | t | 11 | |

Tags :