VMCs are automated machine tools for metalworking applications where the main spindle is aligned vertically. Nowadays professional machine shops and manufacturing plants mostly use CNC-controlled machine tools. A VMC is a machine suitable for machining operations such as milling, drilling, boring, tapping, thread cutting, and more.

Max. X-axis Travel :

1500mmMax. Y-axis Travel :

800mmMax. Z-axis Travel :

700mmMax Workpiece Length :

1700mmMax Workpieces Width :

800mmMax Workpieces Weight :

1500KGApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, Tapping, ScrapingVertical Machining Structural Characteristics

|

VMCs are automated machine tools for metalworking applications where the main spindle is aligned vertically. Nowadays professional machine shops and manufacturing plants mostly use CNC-controlled machine tools. A VMC is a machine suitable for machining operations such as milling, drilling, boring, tapping, thread cutting, and more. |

Vertical Frame Machine Structural Characteristics

|

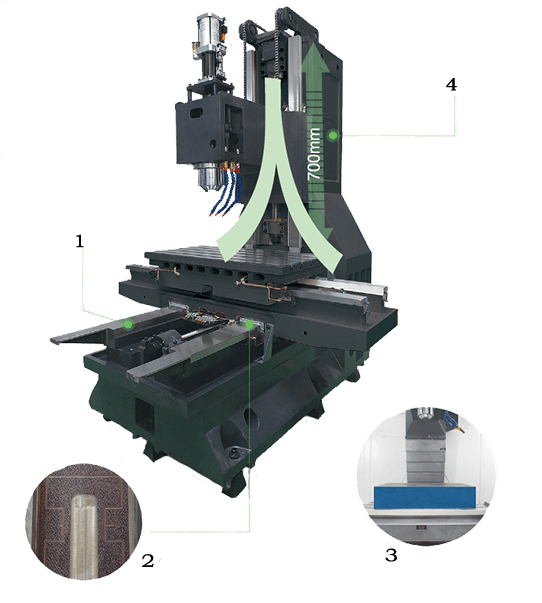

The bed is made of H300 cast iron, quenched, and all slide surfaces are precisely polished and covered with imported wear-resistant leather TURCITE-B. Ensure the accuracy and durability of the machine tool. 1. The wide and thick guide guideways ensure the stability of the machine tool during processing. 2. Scraping process 3. Each box-way type machine is subjected to load aging, and laser ballbar tests before leaving the plant. 4. T-shaped column design, the ultra-wide base for maximum rigidity with Z-axis travel of 700mm. |

When to Choose a Vertical Machining Center or Horizontal Machining Center?

| Vertical Machining Center | Horizontal Machining Center |

|

For 3-axis milling (most common for general machining) When working with smaller to medium-sized parts For high-speed machining of aluminum or softer metals

When budget is a concern (VMCs are more affordable than HMCs) |

For heavy material removal (e.g., large castings) When multi-sided machining is needed without repositioning

For high-volume production with automated pallet systems |

Vertical Machining Frame Structural Characteristics

| Model | YSP-1580 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1500/800/700 |

| Spindle Nose to Worktable | mm | 185-885 | |

| Spindle Center to Column | mm | 810 | |

| Three-Axis Guideway | / | Box Way (Captain Turcite) | |

| Worktable | Worktable Size (L*W) | mm | 1700X800 |

| Maximum Table Load | kg | 1500 | |

| T-Slot | mm | 5-22x135 | |

| Spindle | Spindle taper | type | BBT-50 |

| Spindle speed | rpm | 6000 | |

| Spindle Drive Type | / | Belt | |

| Feedrate | Rapid Traverse(X/Y/Z) | m/min | 10/10/10 |

| Cutting Feedrate(X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic fool Changer | / | ARM Type |

| Type of Tool Shank | type | BT50 | |

| Tool Storage Capacity | Piece | 24 | |

| Max. Tool Diameter (Adjacent) | mm | 105 | |

| Max. Tool Diameter (Empty) | mm | 200 | |

| Max. Tool Length | mm | 350 | |

| Max. Tool Weight | kg | 15 | |

| Tool Change Time | sec | 4.9 | |

| Motor | Spindle Motor | kw | 18.5 |

| Three-Axis Servo Motor | kw | 7.0/4.5/4.5 | |

| Accuracy | Accuracy | mm | ±0.01 |

| Repeatability | mm | ±0.005 | |

| Power Required | Power Requirement | kva | 40 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 4420*3800*3650 |

| Gross Weight | t | 14 | |

Tags :