Horizontal boring machine is a metalworking machine designed for boring holes through materials, such as boring, reaming, and milling. Drills, reamers, milling machines, and other tools are used to perform these operations. His one type of boring machine is a horizontal boring machine with a horizontal spindle. The individual axis movements required to execute the machining cycle are guaranteed by the CNC control system.

Max. X-axis Travel :

4000mmMax. Y-axis Travel :

3200mmMax. Z-axis Travel :

2000mmMax Workpiece Length :

2500mmMax Workpieces Width :

2500mmMax Workpieces Weight :

20TApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingHorizontal Boring Machining Center Structure Characteristics

|

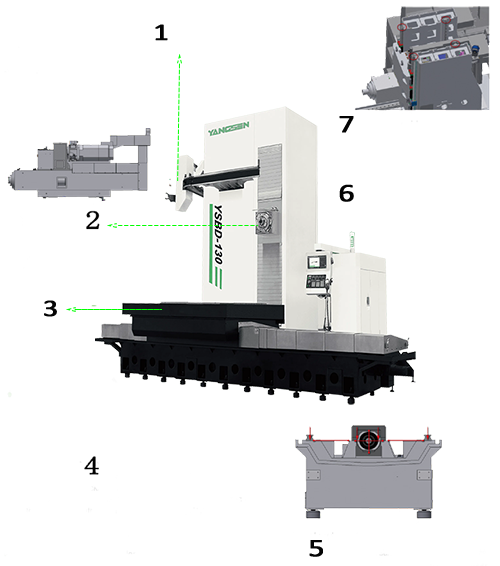

1. Tool magazine structure 40 and 60 tools guideway-type tool magazines, which are driven by a servo tool magazine, improve the overall tool change efficiency. |

|

2. Spindle structure The main shaft installs European structure design, high rigidity, high speed, and low vibration. Low speed and high torque for the spindle. |

|

| 3. The worktable installs super-large grinding gears. It is combined with twin-turbo, vortex anti-backlash structure to ensure accuracy. | |

|

4. Transmission structure The X and Z-axis transmission method installs a direct-acting four-wheel drive. It has stable accuracy. Also, it could eliminate backlash, and improve torsional rigidity and allow angle. The Y-axis installs direct-drive transmission and cooperates with a German reducer to improve torsional rigidity. |

|

|

5. Counterweight structure Use servo frequency conversion hydraulic station, the counterweight of the hydraulic cylinder reduces the axial load and lengthen the life. |

|

|

6. Casting structure design The linear guideway installation surface and the ballscrew center are on the same plane, which makes the ballscrew drive more stable and ensures the stability of the overall accuracy of the machine tool. |

|

|

7. Hanging guideway structure The Y-axis adopts a box-in-box high-rigidity right and left paired lining structure. The Y-axis installs 4 linear guide guideways, 2 front and 2 back, with high rigidity, high precision, and long service life. |

Parameters

| Project | Specification | Unit | YSBD-130/20T |

| Travel | X/Y/Z/W axis | mm | 4000/3200/2000/700 |

| Distance from spindle centerline to worktable surface | mm | 0-3000 | |

| Distance from spindle end face to table center | mm | 60-2260 | |

| track form | Roller guide rail | ||

| Working table | Table size (L*W) | mm | 2500*2500*25T |

| The maximum load capacity of the workbench | kg | 10000 | |

| Table indexing | No/ mm | 0.001 | |

| Spindle | Spindle Taper Hole (Model/Installation Dimensions) | mm | BT50 |

| Spindle speed | rpm | 3000 | |

| Spindle drive mode | Belt (gear box) | ||

| Boring bar diameter | mm | 130 | |

| Feed | X/Y/Z axis rapid feed | m/ min | 2010-10-10 |

| cutting feed | mm/ min | 10000 | |

| Tool changer (optional) | Tool change method | track type | |

| Handle Specifications | type | BT50 | |

| Tool capacity | tools | 40 | |

| Maximum Tool Diameter (Proximity Tool) | mm | 125 | |

| Maximum tool diameter (without adjacent tool) | mm | 250 | |

| Max tool length | mm | 500 | |

| Max tool weight | kg | 25 | |

| Fastest tool change time | sec | 14 | |

| Motor | Spindle motor | kw | Aii30/7000 |

| Three-axis servo motor | kw | AIF40/3000/AIF40B/3000/AIF40/3 000/AIF22 /3000 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy (iso 230-2- 1997) |

positioning accuracy | mm | 0.01 |

| Repeatability | 0.005 | ||

| Power requirement |

power requirements | kva | 80 |

| Air source requirements | Kg/cm | 6~8 | |

| Other | Length*width*height | mm | 7900*6100*6100 |

| Weight | t | 54 |

Standard Accessories

| ARM Type Tool Changer | Rigid Tapping | Dual LED Work Light | Spindle Nose Air Blow |

| Automatic Lubricating System | Heat Exchange for Electric Cabinet | LED 3 Color Warning Light | Leveling Bolts and Pads |

| Semi-Endosed Guard | Coolant Tank & Chip Tray | M30 Auto Off | Rotary Table |

Options

| Optical Linear Scale | Tool Breakage System | Oil Mist Collector | Workpiece & Tool Probe |

| CTS | Chip Conveyor System | Oil Skimmer | Auto Parts Probe Measuring System |

Tags :