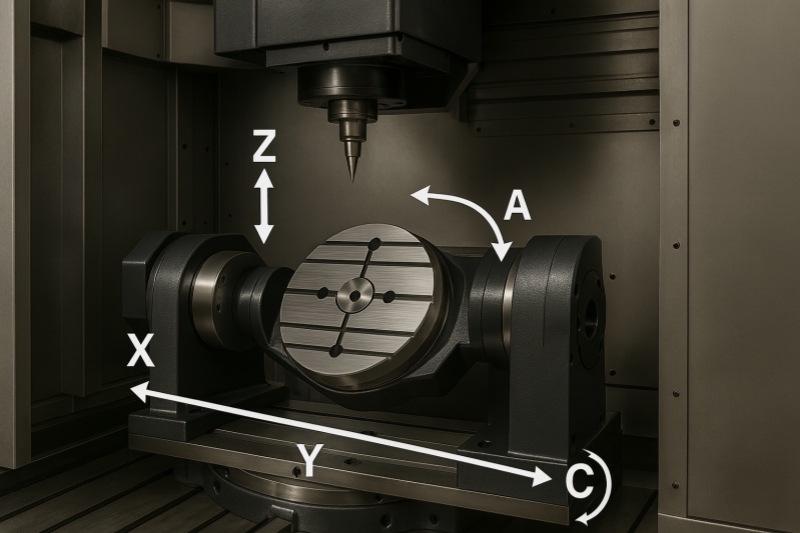

A trunnion table machining center is a type of 5-axis CNC machine that integrates a tilting rotary table (A-axis) with a rotating platter (C-axis). This structure allows the workpiece to tilt and rotate while the cutting tool moves simultaneously, enabling full multi-surface machining in a single setup.

Compared to traditional 3-axis or 4-axis machines, a trunnion-style 5-axis design offers better accessibility to complex angles, reduces repositioning errors, and enhances machining accuracy, repeatability, and efficiency.

Trunnion table machining centers are widely used for aerospace parts, impellers, robotics components, and precision mechanical parts that require tight tolerances, smooth surface transitions, and complex geometries.

Yangsen’s trunnion-style five-axis machining centers combine a high-performance direct-drive rotary table with a rigid machine structure to deliver stable, high-precision 5-axis machining. All models in this series feature a compact cradle-type (trunnion) table that enables simultaneous A/C-axis motion, allowing complex parts to be completed in one setup with improved accuracy and efficiency.

The product line includes drill-tap 5-axis centers, vertical 5-axis machining centers, ram-type 5-axis models, bridge-type structures, and large gantry-type configurations. Across the series, the machines share core technical elements documented in the brochure:

1. High-performance Direct-Drive (DD) rotary tables with zero backlash and high dynamic response.

2. High-rigidity structural designs, including herringbone columns, wide-span guideways, and reinforced castings.

3. High-speed spindle options, such as BT30/BT40/BBT40 and HSK-A63/HSK-A100 motorized spindles.

4. Weight-optimized moving components to enhance dynamic performance.

5. Standard configurations including work lights, warning lights, fully enclosed guards, coolant nozzle systems, air blow, tool setter, toolbox, and internal flushing.

6. Optional configurations such as laser tool setters, workpiece probing, immersion coolant system, linear scales, through-spindle coolant, chip conveyors, and various tool magazine types.

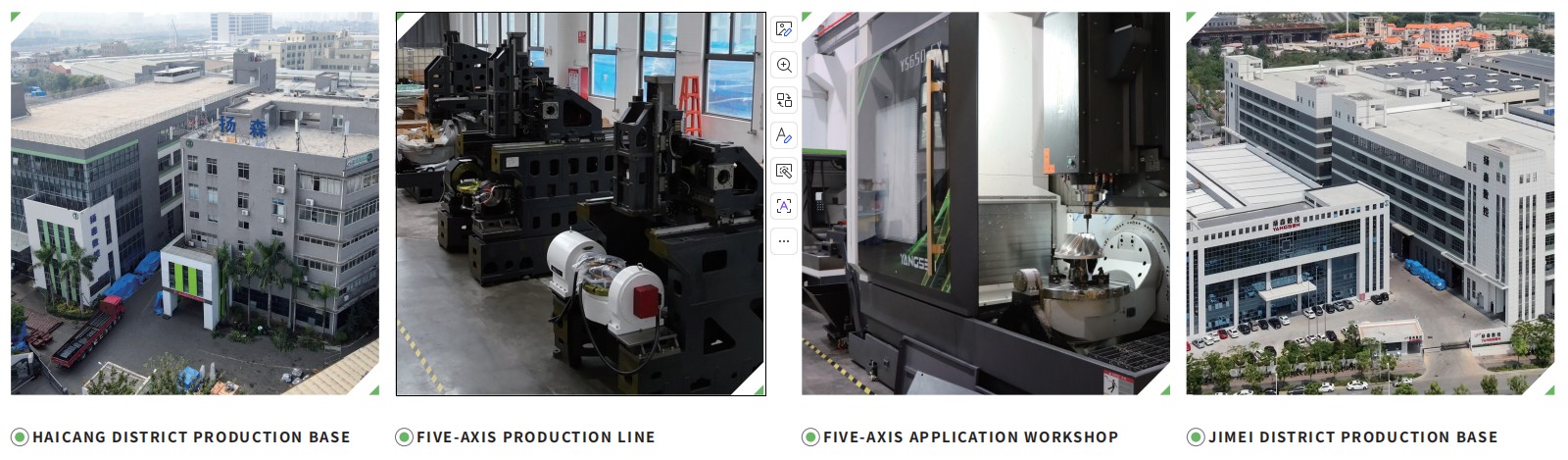

1. Large-Scale Manufacturing Capability

With over 100,000 m² of production facilities located in Xiamen Haicang District and Jimei District, we ensure steady production capacity, efficient delivery, and stable large-volume supply to global partners.

2. Strong R&D Innovation Power

Our 100+ professional R&D team collaborates with leading academic institutions, including Xiamen University, ensuring continuous innovation in machine structure design, precision machining technology, control systems, and intelligent manufacturing.

3. Industry-Leading Intellectual Property Strength

With 100+ authorized core patents, including:

15 invention patents

37 utility model patents

8 software copyrights

We ensure technical leadership, product uniqueness, and strong competitiveness in the CNC machinery industry.

4. Extensive Global Sales & Service Network

With 30+ regional sales and service networks, including:

South China

East China

North China

Overseas Markets

We provide fast response, localized support, and reliable after-sales service for global customers.

Yangsen cradle-style five-axis machining centers are designed for industries that require high precision, complex geometry machining, and multi-surface processing in a single setup. With high-rigidity structural designs, high-speed direct-drive rotary tables, and motorized high-performance spindles, these machines process challenging components efficiently and with exceptional accuracy.

Our five-axis solutions are widely used in aerospace, robotics, automotive power systems, high-precision molds, automation equipment, and UAV manufacturing, where stability, repeatability, and simultaneous multi-axis motion control are critical.

Aerospace & Aviation Components

Our machines are widely applied in the production of blisks, turbine blades, impellers, and complex structural parts used in aircraft and UAV platforms. The high-rigidity architecture and dual direct-drive rotary axes allow precise machining of free-form surfaces with minimal repositioning. This improves machining consistency, reduces setup time, and supports reliable mass production of lightweight, high-strength aerospace components.

Robotics & Automation Systems

Yangsen five-axis machining centers are used to manufacture robotic joints, humanoid hand articulation parts, structural housings, and sensor mounts. These parts often feature organic curves, complex angles, and deep cavities. The machine’s dynamic structure enables smooth, high-speed machining while maintaining micron-level accuracy, which is essential for motion-critical robotic systems.

Precision Mold and Tooling Manufacturing

For mold makers and finishing applications, the bridge-type and gantry-type models deliver the rigidity and thermal stability needed for long cycle finishing passes. These machines are commonly used for high-precision mold cores, graphite and copper electrodes, and complex cavity finishing where surface quality and repeatability are key requirements.

Automotive Powertrain and Engine Components

Yangsen models equipped with higher-torque motorized spindles and large-format trunnion tables are deployed in machining transmission housings, engine blocks, turbine parts, and powertrain system components. The high dynamic performance reduces machining time, while the optimized multi-axis configuration ensures accuracy for critical tolerance features.

3C Electronics & Small Precision Metal Parts

Our compact models are ideal for electronic device housings, small aluminum parts, and high-accuracy connectors. With high-speed spindles and agile motion response, they are suitable for fast-cycle, high-volume production of lightweight precision parts in consumer electronics, medical devices, and automation modules.

1. What is the main difference between drill-tap type, vertical type, ram-type, bridge-type, and gantry-type models?

Each structure is designed for different part sizes and machining requirements:

Drill-tap platforms (U-260T) – compact size, high-speed machining for small precision components

Vertical models (U-320V / U-350V) – for precision machining of small to medium parts

Ram-type (YS-650-5X) – provides better accessibility for aerospace and structural components

Bridge-type (U-400D) – enhanced rigidity for mold and precision finishing

Gantry-type (U-400 / U-700 / U-900) – supports larger components like engine housings, robot joints, and turbine parts.

2. What control systems are available?

Depending on the model, Yangsen machines support Syntec, Huazhong, Siemens, FANUC, and Heidenhain controllers. Control compatibility varies based on configuration and spindle type.

3. What spindle specifications are available?

Spindle configurations include BT30/BBT30 direct-drive, BBT40 spindles, and high-speed HSK-A63 or HSK-A100 motorized spindle options (up to 24,000 rpm). The available spindle type depends on the machine structure and intended application.

4. Do you offer optional measurement and automation accessories?

Yes. Optional configurations include:

Laser tool setter

Workpiece probing system

Coolant-through-spindle (CTS)

Linear scale feedback

Automatic door

Chip conveyor systems

These optional features help improve repeatability, automation capability, and machining efficiency.

5. Can the machine support graphite, titanium, copper, or composite machining?

Yes. Depending on spindle configuration and options, Yangsen machines can support aluminum, stainless steel, tool steel, titanium alloys, copper materials, and graphite (when ordered with the graphite machining package).

6. Do you provide installation, training, and technical support?

Yes. We provide:

On-site installation and commissioning

Operator and maintenance training

Remote technical support

After-sales service and spare parts supply

Support format may vary based on customer location and distributor service structure.

7. How can I determine which model is suitable for my parts?

Simply share your part material, size range, machining tolerance, and expected annual production volume. Our engineering team will recommend the appropriate model, spindle type, and configuration based on real application requirements.