Our CNC vertical machining centers are designed to meet your high-performance machining needs. With vertical spindle orientation, advanced automation, and unmatched precision, they deliver superior machining results for complex parts. Whether you're in aerospace, automotive, or moldmaking, our machines ensure reliability, speed, and accuracy.

No that expensive, compared with HMC.

Easy set-up: CNC Vertical Machining Centers are also known for their flexibility and programmability, allowing for quick setup changes.

Much easier to manage for your operators.

More cost-effectiveness: CNC VMCs are often more cost-efficient than other types of machines due to their efficiency and dependability.

High accuracy and precision: If you need high-processing for your parts, CNC vertical machining centers are able to achieve high levels of accuracy and repeatability due to their ability to control multiple axes simultaneously.

Strong repeat-ability: VMC is more attractive you, for Both smaller shops and large machine operations due to repeat-ability

Fast cycle times: all manufacturing eager faster production and more profit. VMC can significantly cut down on production time, which means faster throughput and quicker turnaround times for your projects.

With these benefits in mind, a CNC vertical machining center is an essential tool for any shop. Whether you need a heavy-duty machine to handle precision workpieces or a more affordable model to tackle simple tasks, you are sure to find the perfect solution for your needs with these versatile machines.

For additional help in selecting the right type of VMC, contact our team of experienced CNC machining experts. They are here to provide you with the insight and advice needed to make an informed decision when it comes to your next CNC machine purchase.

|

The machine tool of this product is equipped with name brand components in the industry, equipped with a large torque, high speed motor and a super rigid bed design. Taking into account high torque, high speed and high precision, it is suitable for processing all kinds of products and molds. |

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

||

|

Cuttin 5mm |

|

Cutter diameter Ø60 |

|

Cutting Tapping M24 |

|

||

|

Cutter |

Ø125mm*5T |

Cutter |

Ø60mm*2T |

Cutter |

M24*3P |

||

|

Spindle speed |

1000rpm |

Spindle speed |

1200rpm |

Spindle speed |

150rpm |

||

|

Feed |

F600 |

Feed |

F100 |

Feed |

F450 |

||

|

Width |

56mm |

Width |

60mm |

Width |

40mm |

||

Vertical Frame Machine Structural Characteristics

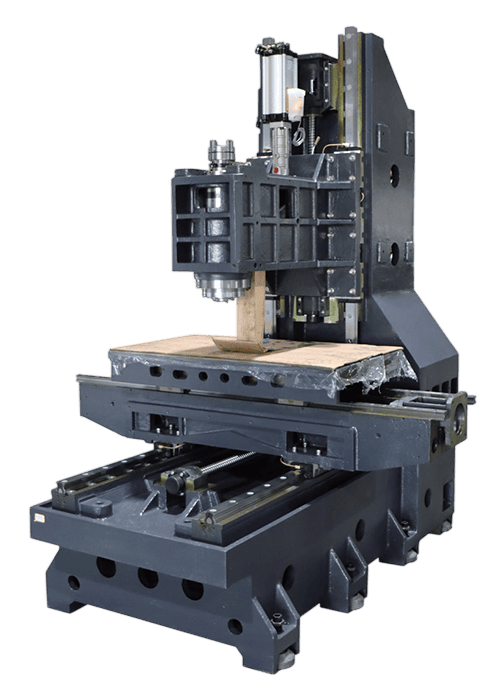

YSV-966 Opto-Mechanical Characteristics

|

Dual pneumatic system Dual pneumatic units are standard for enhanced machining stability and precision. Spindle BBT40 taper with 150mm flange 5 high-capacity bearings with ring-cooling Optional HSK-A63 motorized spindle Column Structure Double-walled design providing superior rigidity. Precision Encoders Optional Heidenhain/Fagor linear scales (士5μm positioning accuracy) Worktable & Travels able dimensions:1020 ×570mm Axis travels: X=850mm/Y=590mm/Z=590mm Reinforced Base 1200mm span high-rigidity bed with precision casting Thermal Management THK C3-grade ballscrews (Japanese standard) SK precision bearings in 3+2 preload configuration Pre-stretched assembly for thermal drift control Foundry Quality Bed manufactured with high-grade HT300 castings (300MPa tensile strength) |

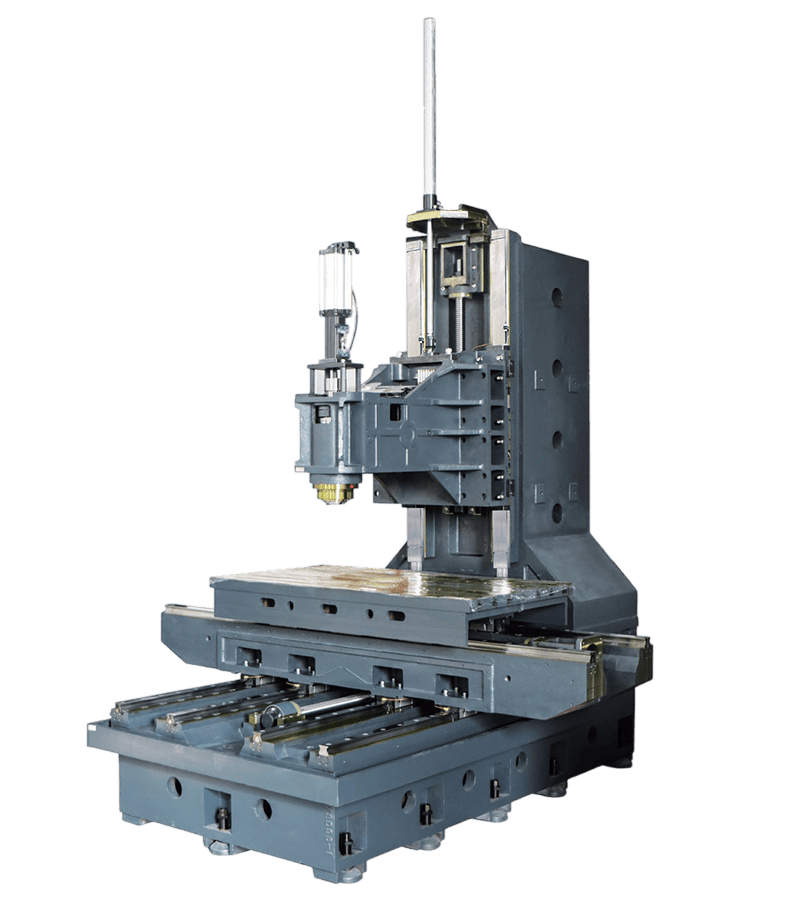

YSL-1060 Opto-Mechanical Characteristics

|

Dual pneumatic system Dual pneumatic units are standard for enhanced machining stability and precision. Spindle BBT40 taper with 150mm flange 5 high-capacity bearings with ring-cooling Column Structure Double-walled design providing superior rigidity. Precision Encoders Optional Heidenhain/Fagor linear scales (士5μm positioning accuracy) Worktable & Travels Table dimensions:1100 ×570mm Axis travels: X=1000mm/Y=600mm/Z=680mm Reinforced Base 1200mm span high-rigidity bed with precision casting Thermal Management THK C3-grade ballscrews (Japanese standard) NSK precision bearings in 3+2 preload configuration Pre-stretched assembly for thermal drift control Foundry Quality Bed manufactured with high-grade HT300 castings (300MPa tensile strength) |

|

Safety Door Automatic Lubricating System Fully Enclosure Guard Air Gun |

Rigid Tapping Heat Exchange for Electric Cabinet Spindle Coolant Nozzles Coolant Gun |

Dual LED Work Light LED 3 Color Warning Light Coolant Tank & Chip Tray Tool Box |

Spindle Nose Air Blow Leveling Bolts and Pads M30 Auto Off Maintenance and Operational Manual |

Options

|

Optical Linear Scale CTS Workpiece & Tool Probe |

Coolant Gun Tool Breakage System Chip Conveyor System |

Oil Mist Collector Oil Skimmer Rotary Table |

12000rpm DDS Spindle 15000rpm DDS Spindle HSK-63-18000 Built-In Moto |

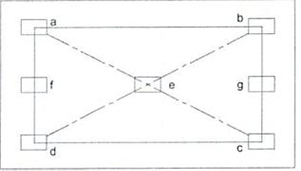

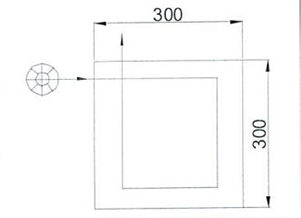

| No. | Specification | Chart | Standard (not exceeding) mm | |

|

1 |

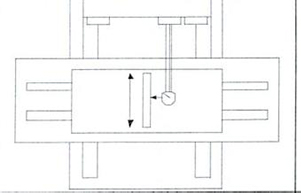

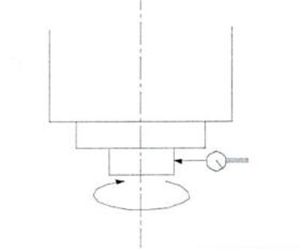

Flatness of the worktable surface |  |

0.04/1000mm | |

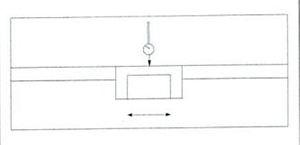

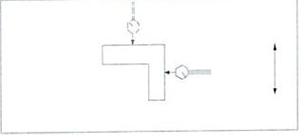

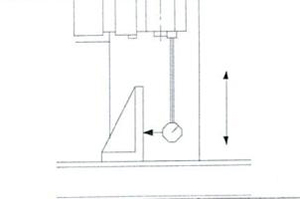

| 2 | X-table flatness |  |

0.01 L=500mm |

|

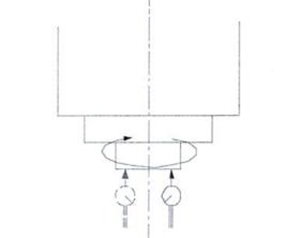

| 3 | Y-table flatness |  |

0.02 | |

| 4 | Parallelism between the X-axis movement and the table surface |  |

0.02 | |

| 5 | Parallelism between the Y-axis movement and the table surface |  |

0.02 | |

| 6 | Parallelism between the X-axis movement and the surface of the table track |  |

0.025/ full length | |

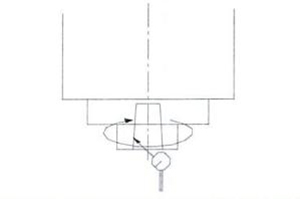

| 7 | Perpendicularity between the X and Y axis movements |  |

0.015 L=300mm |

|

| 8 | Straightness of Z-axis movement: X-Z direction |  |

0.01 L=500mm |

|

| 9 | Straightness of Z-axis movement: Y-Z direction |  |

0.01 L=500mm |

|

| 10 | Perpendicularity of the spindle to the table surface |  |

0.02 D=300mm |

|

| 11 | Straightness between the spindle and the Z-axis | Near spindle |  |

0.007 |

| 300mm from the spindle | 0.015 | |||

| 12 | Spindle backlash |  |

0.005 | |

| 13 | Spindle run-out |  |

0.005 | |

| 14 | Spindle head run-out |  |

0.005 | |

| 15 | Spindle taper run-out |  |

0.005 | |

| 16 | Position accuracy | X/Y/Z axis direction | 0.008/0.008/0.008 | |

| 17 | Repeat positioning accuracy | X/Y/Z axis direction | 0.005/0.005/0.005 | |

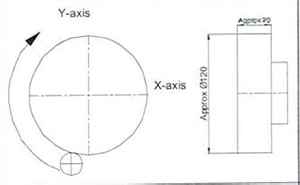

| 18 | Circular interpolation accuracy |  |

Roundness:0.01 | |

| 19 | Surface milling accuracy |  |

Flatness: 0.008 | |

CNC Vertical Machining Centers have a wide range of applications.

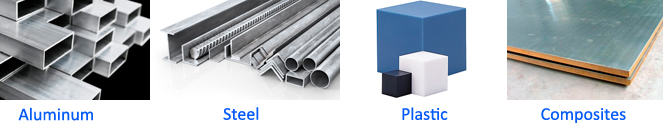

They can process various materials such as aluminum, steel, plastics, and composites with high accuracy and repeatability.

Furthermore, they are capable of performing a variety of operations like drilling, boring, milling, and turning with ease.

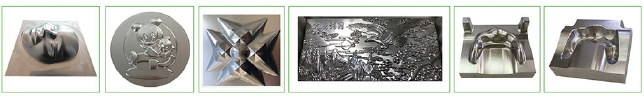

CNC Vertical Machining Centers are an extremely versatile tool, capable of producing high-quality parts quickly and efficiently, which enables the VMC mainly for processing complex parts such as plates, discs, molds, and small shells.

CNC Vertical Machining Centers are widely used in automotive, medical, electronics, and other industries where precision machining is required. With the right programming and operator skills, CNC Vertical Machining Centers can achieve very tight tolerances and produce complex shapes with ease.

They are often used to produce custom parts in short lead times with minimal capital investment.

They can be used for both low and high-volume production runs. By taking advantage of the latest in technology, they have allowed manufacturers to increase their productivity while reducing costs.

The vertical machining center can complete the processes of milling, boring, drilling, tapping, and thread cutting. The vertical machining center is at least three-axis and two-linkage and generally can realize three-axis and three-linkage. Some can carry out 5-axis, and 6-axis control.

They are often used to produce custom parts in short lead times with minimal capital investment.

They can be used for both low and high-volume production runs. By taking advantage of the latest in technology, they have allowed manufacturers to increase their productivity while reducing costs.

Compared with horizontal machining centers (HMC), the height of the vertical CNC machining centers column is limited, and the processing range of the box-type workpiece should be reduced, which is the disadvantage of the vertical machining center.

However, the workpiece clamping and positioning of the vertical machining center is convenient; the movement trajectory of the cutting tool is easy to observe, the debugging program is convenient to check and measure, and the problem can be found in time, and the shutdown processing or modification can be carried out;

the cooling condition is easy to establish, and the cutting fluid can directly reach the cutting tool and the machined surface;

The three coordinate axes are consistent with the Cartesian coordinate system, and the intuitive feeling is consistent with the viewing angle of the pattern, and the chips are easy to remove and fall, so as to avoid scratching the processed surface.

Compared with the corresponding horizontal machining center, the structure is simple, the floor area is small, and the price is lower.

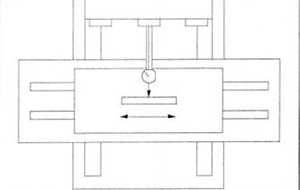

Design and construction govern a vertical machining center’s ability to machine parts to tight tolerances with accuracy and repeatability.

No matter it’s for a small toolroom, a workshop, or a production house, there are a lot of factors to consider when it comes to acquiring a vertical machining center (VMC). No. 1 important thing is the application and workpiece(s) and the needs of a workshop’s various departments. We need to choose the appropriate VMC according to the workpiece processing requirements and production volume

Among the numerous machine tool characteristics to scrutinize before buying a VMC are machine structure and stability. The stability and rigidity of the machine are one of the most important prerequisites to ensure machining accuracy.

Without considering the accuracy and repeatability, the machine price is meaningless. We are not encouraging customers to buy very expensive equipment. What we want to emphasize is to buy a VMC with high precision and high mass production capacity with the right money.

So the ability to process parts to a tight tolerance and mass production volume must be considered. That is where a machine’s design and construction come into play. Its ability to achieve the required precision and accuracy, and the number of parts to be machined, will influence the quality of the machine that’s needed and the price it will demand. The higher the accuracy and the larger the number of parts to be produced, the higher the benefit the user can expect.

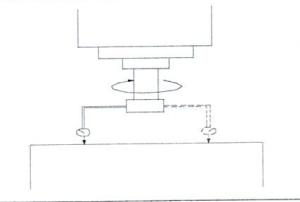

Because of the characteristics of a V8-frame design, a VMC’s thermal stability can be guaranteed. Just as a sturdy house requires a solid foundation, the same is true for a stable machine tool. Most superior VMC structures are engineered using finite element analysis (FEA) software. It’s not simply the weight of the machine that matters; it’s also its design and the placement of the weight that determines its rigidity and stability.

Some machines are equipped with large ballscrews and a different pitch to enhance accuracy. Laser and ballbar calibration can be used to ensure better part accuracy, but only up to a point. A poorly designed machine will never consistently produce high-accuracy parts.

Machine stability is also mainly affected by thermal growth. The high spindle speed (10000rpm) generates heat, as does the ball screw, machine work table, and guideway system.

Also, the faster the machine moves, the more friction, and heat it generates. This heat can significantly change the size and position of machine components, causing the machine to "bigger" or deform, and the position of the spindle or cutting tool to move unpredictably. Because of these unpredicted transitions, one of the biggest challenges with five-axis machining is that the control system cannot always calculate the exact location of the axis pivot point.

To solve the problem caused by heating, coolers are used to cool the ball screws and control the temperature of the spindle and spindle housing. Thermal sensors that measure and automatically counteract machine heating growth are located at key points of the machine. These provisions are especially important in tooling applications where longer processing times and more heating. If not controlled, thermal distortion in the machine can cause unacceptable errors in the shape or dimensions.

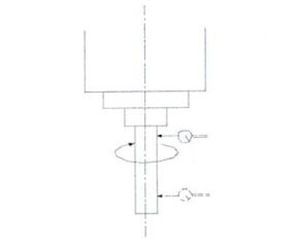

High-end machines often use a graduated system on each axis rather than the standard encoder feedback system offered by most VMCs. Anti-backlash systems are often designed into ball screw nuts to improve machine repeatability.

Likewise, certain rail systems are designed for high-speed, low-friction operation to help control thermal growth. Of course, all these special features come at a higher price.

High-performance VMC spindles range in price from $4,000 to $30,000. There's a big difference in design between a $50,000 "value" machine and a $300,000 high-end VMC. That said, if accuracy requirements are not particularly stringent and the number of parts is manageable, a value-for-money machine will suffice.

The VMC performance is also greatly affected by the workshop foundation and placement where the machine is put on.

In fact, machining at high rates with rapid axis acceleration should require the machine to be tied down on the firm floor.

Heavy deep cutting on some materials also may cause excessive vibration, requiring the machine to be securely anchored to the firm floor. In some cases, it may be necessary to install a steel-reinforced concrete base that is isolated from the surrounding floor. So we have 4 friendly suggestions for you:

It should be far away from vibration sources, direct sunlight and heat radiation should be avoided, and the influence of moisture and airflow should be avoided. If there is a vibration source near the CNC machine tool, an anti-vibration ditch should be set around the machining center. Otherwise, it will directly affect the machining accuracy and stability of the CNC machine tool and will cause poor contact and failure of electronic components, which will affect the reliability of the machining center.

Generally, the machining center is installed in the machining workshop, not only does the ambient temperature change greatly, and the use conditions are poor, but also there are many kinds of electromechanical equipment, resulting in large fluctuations in the power grid. Therefore, the location where the machining center is installed requires strict control of the power supply voltage. The power supply voltage fluctuation must be within the allowable range and remain relatively stable. Otherwise, it will affect the normal work of the CNC system of the machining center.

The ambient temperature of the CNC machining center is lower than 30 degrees Celsius, and the relative temperature is less than 80%. Generally speaking, there is an exhaust fan or cooling fan inside the CNC electric control box to keep the electronic components, especially the central processing unit, at a constant temperature or with little change in temperature difference. Excessive temperature and humidity will reduce the life of control system components and lead to more failures. The increase in temperature and humidity, and the increase of dust will cause bonding on the integrated circuit board and cause a short circuit.

When using the machining center, the user is not allowed to change the parameters set by the setting of these machining center parameters is directly related to the dynamic characteristics of each part of the machining center. Only the gap compensation parameter value can be adjusted according to the actual situation.

There are 4 Series for CNC vertical machining centers:

YSV: 2-line tracks and 1-hard rail.

| Model | YSV-800 | YSV-855 | YSV-957 | YSV-1060 | YSV-1160 | YSV-1265 | YSV-1580 |

| Travel X/Y/Z axis mm | 800/450/550 | 850/550/550 | 900/570/680 | 1000/600/680 | 1100/600/600 | 1200/680/680 | 1500/800/700 |

YSL: 3--line tracks

| Model | YSL-1060 | YSL-1270 | YSL-1375 | YSL-1580 | YSL-1890 |

| Travel X/Y/Z axis mm | 1000/600/680 | 1200/700/780 | 1300/750/600 | 1500/800/700 | 1800/900/600 |

YSP: 3-hard rail

| Model | YSP-857 | YSP-1060 | YSP-1270 | YSP-1580 | YSP-1890 |

| Travel X/Y/Z axis mm | 800/500/700 | 1000/600/600 | 1200/700/600 | 1500/800/700 | 1800/900/680 |

YS: spiecal machine, YSD4 (quad-haed spindel), YSD8(eight-spindle), YSCP-835 (Shovel machine), YS650-5AX (5 axis)

| Model | YSD-260 | YSD8-565 | YSCP-835 | YSP-650-5AX |

| Travel X/Y/Z axis mm | 260/280/200 | 550/650/550 | 800/450 | 700/450/400 |

Sincerely hope the above information can help you to buy the right VMC at the right price.

Please click the above items for more information.