The CNC horizontal boring machine is equipped with a large worktable and has a large carrying capacity. Proper sizing of the hydraulic clamping system while allowing heavy cutting capabilities. Ultra-rigid, compact spindle head housing that provides cooling and lubrication for all heat sources in the spindle head to minimize thermal costs.

Max. X-axis Travel :

2500mmMax. Y-axis Travel :

2000mmMax. Z-axis Travel :

1500mmMax Workpiece Length :

1400mmMax Workpieces Width :

1600mmMax Workpieces Weight :

8TApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingHorizontal Boring Machining Center Structure Characteristics

|

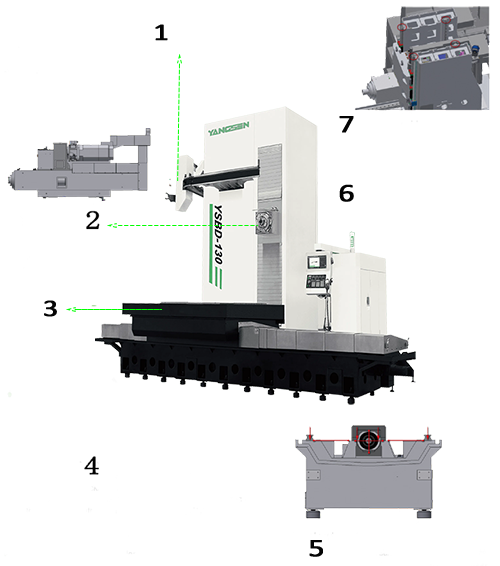

1. Tool magazine structure 40 and 60 tools guideway-type tool magazines, which are driven by a servo tool magazine, improve the overall tool change efficiency. |

|

2. Spindle structure The main shaft installs European structure design, high rigidity, high speed, and low vibration. Low speed and high torque for the spindle. |

|

| 3. The worktable installs super-large grinding gears. It is combined with twin-turbo, vortex anti-backlash structure to ensure accuracy. | |

|

4. Transmission structure The X and Z-axis transmission method installs a direct-acting four-wheel drive. It has stable accuracy. Also, it could eliminate backlash, and improve torsional rigidity and allow angle. The Y-axis installs direct-drive transmission and cooperates with a German reducer to improve torsional rigidity. |

|

|

5. Counterweight structure Use servo frequency conversion hydraulic station, the counterweight of the hydraulic cylinder reduces the axial load and lengthen the life. |

|

|

6. Casting structure design The linear guideway installation surface and the ballscrew center are on the same plane, which makes the ballscrew drive more stable and ensures the stability of the overall accuracy of the machine tool. |

|

|

7. Hanging guideway structure The Y-axis adopts a box-in-box high-rigidity right and left paired lining structure. The Y-axis installs 4 linear guide guideways, 2 front and 2 back, with high rigidity, high precision, and long service life. |

Feature of Horizontal Boring Machining Center

Horizontal Spindle Orientation

Allows gravity-assisted chip evacuation, reducing recutting and improving surface finish.

Ideal for deep boring and heavy-duty machining.

Large Work Envelope

Designed for big parts (e.g., engine blocks, gearboxes, dies, and industrial machinery components).

Precision Boring Capabilities

High-accuracy spindle with fine adjustments for tight-tolerance boring (e.g., bearing housings, large bores).

Multi-Axis Movement

Typically 4-axis (X, Y, Z, B) or 5-axis (with rotary table) for complex machining without repositioning.

Pallet Changer System (Optional)

Parameters

| Subject | Specification | Unit | YSBD-110/8T |

| Travel | X/Y/Z/W-axis | mm | 3000/2000/1500/550 |

| Spindle Nose to worktable | mm | 65-2065 | |

| Spindle center to Column | mm | -2050 | |

| X/Y Guideway | Roller guide | ||

| Worktable | Worktable Size (LxW) | mm | 1400*1600 |

| Maximum Table Load | kg | 8000 | |

| Table Screw | No/mm | 0.001 | |

| Spindle | Spindle Type(Model number / mounting size) | mm | BT50 |

| Spindle Speed | rpm | 3000 | |

| Spindle Drive Type | gear type | ||

| Boring bar diameter | mm | φ110 | |

| Feedrate | Rapid Traverse(X/Y/Z) | m/min | 10/10/10/6 |

| Cutting Feedrate (X/Y/Z) | mm/min | 10000 | |

| Tool Changer (Options) |

Automatic Tool Changer | track type | |

| Type of Tool Shank | type | BT50 | |

| Tool Storage Capacity | tools | 40 | |

| Max. Tool Diameter (Adjacent) | mm | 125 | |

| Max.Tool Diameter (Empty) | mm | 250 | |

| Max.Tool Length | mm | 500 | |

| Max.Tool Weight | Kg | 25 | |

| Fastest Tool Change Time | sec | 14 | |

| Motor | Spindle Motor | kw | Aii22/8000 |

| Three-Axis Servo Motor | kw | AIF30/4000/AIF40B/3000/AIF30/4000/AIF22/3000 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy | X/Y/Z/W positioning accuracy | mm | 0.01/0.01/0.01/0.012 |

| X/Y/Z/W repeated positioning accuracy | mm | 0.005/0.008/0.005/0.008 | |

| Power Required |

Power Requirement | kva | 50 |

| Air Pressure Requirement | Kg/cm | 6~8 | |

| Other | External Dimensions((L/W/H)) | mm | 6800*6000*5500 |

| Gross Weight | t | 34.5 |

|

Aerospace – Turbine housings, engine frames.

Automotive – Cylinder blocks, transmission cases.

Energy – Wind turbine hubs, hydraulic components.

Heavy Machinery – Gearboxes, pump housings.

Mold & Die Making – Large cavity machining.

|

Tags :