Spindle performance has a direct impact on machining accuracy, cutting stability, and surface finish in CNC machining. Issues such as vibration, noise, overheating, or unstable cutting are often linked to the spindle motor rather than the tooling or programming.

This leads to a key question: how do different types of CNC spindle motors affect machining performance?

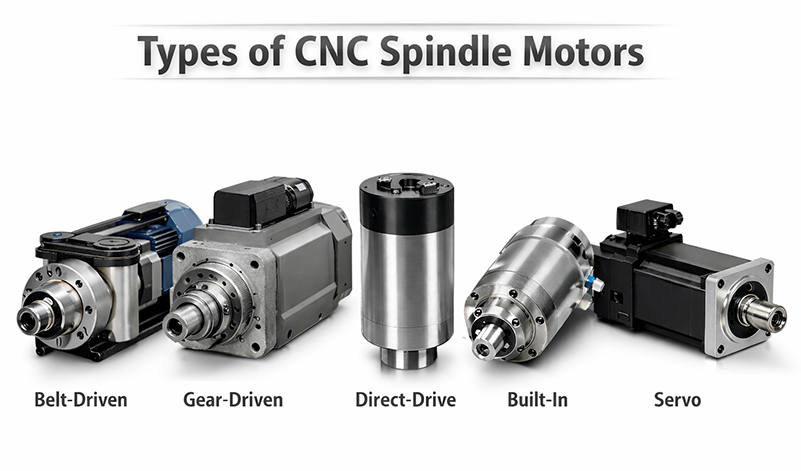

Although they may appear similar, spindle motors differ significantly in structure, drive method, and performance capabilities.

Not all CNC spindle motors are the same. Some are designed for high torque and heavy cutting, while others focus on high speed, precision, or smooth control.

In this article, we'll introduce the main types of CNC spindle motors and explain their differences to help you better understand which options suit different machining needs.

Before diving into the different types, let's get one thing clear first: what exactly is a CNC spindle motor?

Simply put, it's the component that makes the cutting tool spin.

No rotation, no cutting — it's that essential.

The spindle motor converts electrical power into controlled rotational motion, allowing the tool to cut material at specific speeds and torque levels. Every time you adjust RPM, switch cutting modes, or run a high-speed operation, the spindle motor is doing the heavy lifting behind the scenes.

Why does this matter?

Because spindle performance affects everything — cutting stability, surface finish, noise, vibration, and even tool life. A spindle motor that's not well matched to the job can lead to chatter, heat buildup, or inconsistent results, no matter how good your tooling or programming is.

And here's the key point many people miss: not all CNC spindle motors work the same way.

Different designs handle speed, torque, and load very differently.

That's why understanding the types of CNC spindle motors isn't just technical knowledge — it's practical insight that helps you get better machining results.

Let's break it down.

Now that we know what a CNC spindle motor does, let's talk about the real question:

What kinds of spindle motors are actually used in CNC machines?

You'll quickly notice one thing — there isn't a “best” spindle motor.

Each type is designed with a specific machining goal in mind, whether that's torque, speed, precision, or cost control.

Let's look at the most common types one by one.

This is one of the most traditional and widely used spindle motor designs.

In a belt-driven system, the motor transmits power to the spindle through belts and pulleys. It's a simple setup — and that simplicity is exactly why it's still popular.

Why choose it?

Cost-effective and reliable

Easy to maintain and repair

Good vibration absorption during heavy cutting

Where does it fall short?

Limited maximum spindle speed

Power loss through belt transmission

Lower precision compared to direct-drive designs

Best suited for:

General machining, roughing operations, and applications where cost and torque matter more than ultra-high speed.

If belt-driven spindles focus on simplicity, gear-driven spindles focus on torque.

Instead of belts, this design uses an internal gearbox to multiply torque, making it ideal for heavy-duty machining.

Why choose it?

Very high torque output

Stable under heavy cutting loads

Ideal for large workpieces and deep cuts

Where does it fall short?

Higher noise levels

More complex internal structure

Increased maintenance requirements

Best suited for:

Heavy roughing, large parts, and applications where cutting power is more important than speed.

This is where things start to feel more “modern.”

In a direct-drive spindle, the motor is directly coupled to the spindle shaft — no belts, no gears. That means fewer moving parts and much higher precision.

Why choose it?

Excellent rotational accuracy

Minimal vibration and backlash

Better surface finish

Fast acceleration and deceleration

Where does it fall short?

Higher cost

Heat control becomes more critical

Requires high-quality manufacturing and control systems

Best suited for:

Precision machining, fine finishing, and applications where accuracy and surface quality are critical.

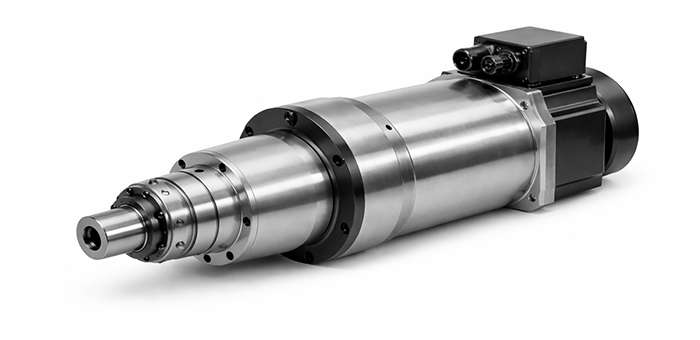

In this design, the motor is fully integrated inside the spindle housing itself. Compact, powerful, and built for speed.

You'll often see these in high-speed machining centers.

Common subtypes

Air-cooled built-in spindle

Liquid-cooled built-in spindle

Why choose it?

Extremely high spindle speeds

Outstanding dynamic performance

Compact, space-saving design

Where does it fall short?

Higher initial investment

Complex cooling systems

Maintenance usually requires specialized support

Best suited for:

High-speed machining, mold finishing, and precision parts require smooth, stable rotation.

Servo spindle motors emphasize control.

They are designed to work closely with the CNC system, allowing precise speed regulation and smooth transitions — especially useful for tapping and variable-speed operations.

Why choose it?

High precision and repeatability

Smooth speed control

Excellent for rigid tapping

Where does it fall short?

More complex control setup

Higher system cost

Requires advanced CNC integration

Best suited for:

Tapping, precision machining, and operations requiring accurate speed control.

|

Spindle Motor Type |

Drive Method |

Speed Capability |

Torque Output |

Precision Level |

Typical Applications |

|

Belt-Driven Spindle |

Belt & pulley |

Medium |

Medium to high |

Medium |

General machining, roughing, cost-sensitive production |

|

Gear-Driven Spindle |

Internal gearbox |

Low to medium |

Very high |

Medium |

Heavy cutting, large workpieces, deep milling |

|

Direct-Drive Spindle |

Direct coupling |

Medium to high |

Medium |

High |

Precision machining, fine finishing |

|

Built-In Spindle |

Motor integrated in spindle |

High to very high |

Medium |

Very high |

High-speed machining, mold finishing |

|

Servo Spindle Motor |

Servo-controlled drive |

Medium |

Medium |

High |

Tapping, variable-speed precision operations |

Are all CNC spindle motors interchangeable?

A: Not really. Different CNC spindle motors are designed for specific speed, torque, and control requirements. Swapping spindle motor types without considering machine structure and application can limit performance or even cause reliability issues.

Is a direct-drive spindle more accurate than a belt-driven spindle?

A: In most cases, yes. Direct-drive spindles eliminate belts and gears, reducing vibration and backlash to achieve better rotational accuracy and surface finish.

Why are gear-driven spindles still used if they are noisy?

A: Because torque matters. Gear-driven spindle motors provide robust, stable torque for heavy cutting and large workpieces, where cutting power is more crucial than speed or noise level.

Is a higher spindle speed always better?

A: Not necessarily. High spindle speed is useful for light cutting and finishing, but heavy machining often requires torque and rigidity rather than RPM. The best spindle motor depends on the actual machining task.

Can the wrong spindle motor reduce tool life?

A: Yes. Excessive vibration, unstable speed, or poor torque control can increase tool wear and heat buildup. A well-matched spindle motor helps extend tool life and maintain consistent cutting performance.

How should I choose the right CNC spindle motor type?

A: Start by considering your materials, cutting style (roughing or finishing), speed requirements, and accuracy goals. Matching the spindle motor type to real machining needs usually delivers better results than simply choosing the highest specification.

Choosing the right CNC spindle motor starts with understanding the different types — belt-driven, gear-driven, direct-drive, built-in, or servo — and how they support different machining goals.

Now that you know the key differences, you're in a much better position to make informed decisions about spindle performance, accuracy, and efficiency.

Take a moment to consider your materials, cutting style, and production priorities, and identify the spindle motor type that truly fits your machining needs.

Better machining results don't come from guesswork — they start with the right spindle motor.