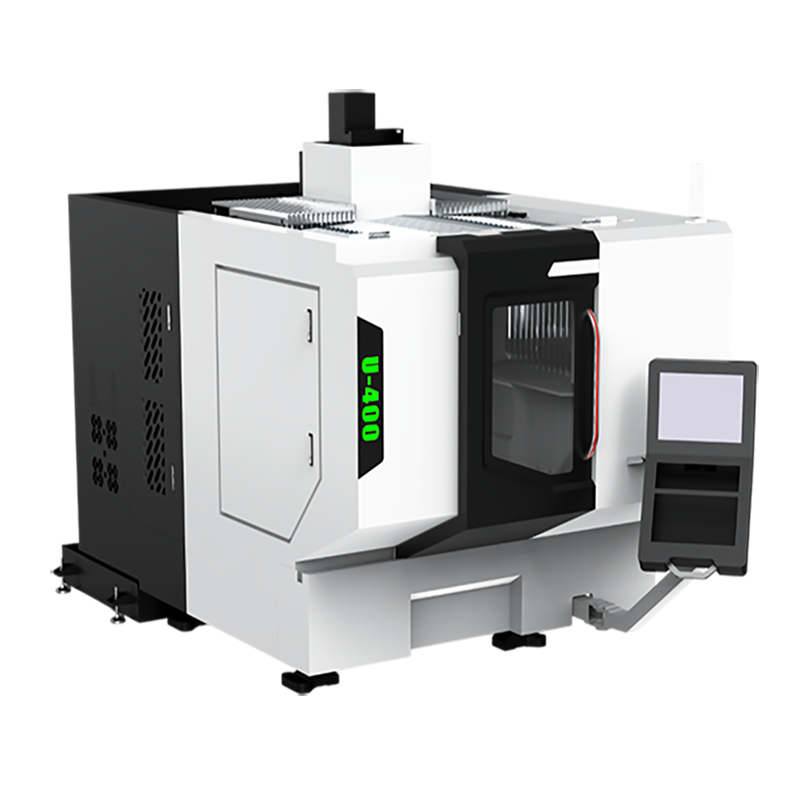

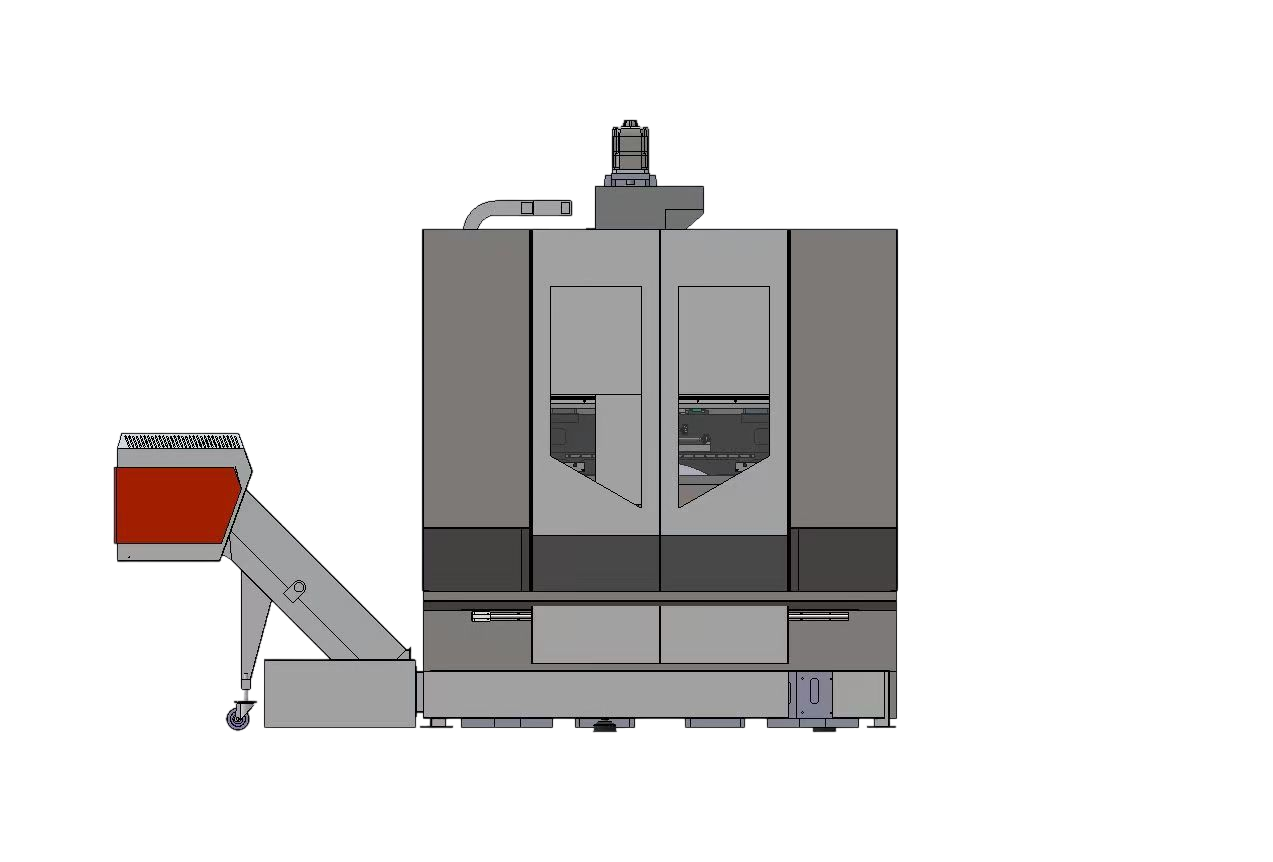

Vertical gantry cradle 5 Axis machining center adopts U The type base is combined with the bridge-type upper structure into a complete box structure, forming a fully enclosed force flow circuit, so the structure has high rigidity and strong stability. The symmetrical structure makes the thermal deformation error small, the three-axis drive is close to the center of gravity, the motion responsiveness and synchronization are excellent, the machine tool processing accuracy , finish are high, and the stability is strong;

Max. X-axis Travel :

460mmMax. Y-axis Travel :

460mmMax. Z-axis Travel :

400mmMax Workpieces Weight :

200/100KGFeatures of the Whole Machine

|

1. The tool magazine is equipped with a variable frequency drive, and the tool arm is controlled by a frequency converter, which effectively improves product processing efficiency; 2. Configuration φ150- HSKA 63-16000 rpm High frequency electric spindle has the advantages of high power and wide power range. Spring clamping and hydraulic release. The spindle is equipped with a coaxial ring encoder, which can synchronously feedback the instantaneous speed and rotation angle of the spindle, and high-speed continuous Good processing performance, strong overload capacity, and rigid tapping function. 3. The spindle bearing is lubricated with grease, and has good high-speed performance. The spindle tool is clamped by spring and released by hydraulic pressure. 4.The labyrinth seal at the front end of the spindle is equipped with air pressure protection, and the spindle taper hole is blown clean with pressurized air. Dust and chip protection. |

Optical Machine Features

1. Use Taiwan PMI Roller rail, Taiwan PMIC3 Grade screw, Japan NACHI Original bearings, pre-tensioned to prevent thermal displacement;

2. The bed casting is made of HT300 Resin sand casting, after overall annealing, natural aging and two high-frequency vibration aging treatments, with high rigidity High stability, long-lasting and non-deformable effect;

3. Vertical gantry cradle 5 Axis machining center adopts U The type base is combined with the bridge-type upper structure into a complete box structure, forming a fully enclosed force flow circuit, so the structure has high rigidity and strong stability. The symmetrical structure makes the thermal deformation error small, the three-axis drive is close to the center of gravity, the motion responsiveness and synchronization are excellent, the machine tool processing accuracy , finish are high, and the stability is strong;

4. The semi-open cradle turntable installation structure allows customers to easily achieve single drive double support, double drive double support, roller cam drive, DD Motor drive and different disks and A The axis center high cradle module configuration requirements. Can meet the complex surface and multi-faceted product processing Work demand;

5. Foreign Economics 150mm High rigidity HSKA63 Electric spindle, ring spray design.

Technical Parameters

| Travel | X/Y/Z axis | mm | 460/460/400 |

| Distance from spindle nose to worktable | mm | 140-540 | |

| Track form | Roller Guide Rails | ||

| Turntable | Turntable table size | mm | φ400 |

| Table distance from rotation center | mm | 25 | |

| Maximum load-bearing capacity of the workbench (0 °/90 ° ) | Kg | 200/100 | |

| T Groove | No/mm | 8-14x45 ° | |

| Rotation Angle | Spend | A/C: ±110/360 | |

| Spindle taper hole (model/installation dimensions) | HSKA63 | ||

| Spindle | Spindle speed | rpm | 16000 |

| Spindle drive mode | Electric spindle | ||

| Feed | X/Y/Z Axis rapid feed | m/min | 36/36/36 |

| Maximum cutting feed | mm/min | 10000 | |

| Tool Changing Device | Tool changing method | Translational | |

| Tool handle specifications | type | HSKA63 | |

| Tool capacity | tools | 18 | |

| Maximum tool diameter (cutting tool) | mm | 80 | |

| Maximum tool diameter (without tool) | mm | 80 | |

| Maximum tool length | mm | 250 | |

| Maximum tool weight | kg | 8 | |

| Fastest tool change time | sec | 4 | |

| Motor | Spindle motor | kw | 20 |

| Three-axis servo motor | kw | S08-AM28-30-F4/S08-A M28-30-F4/S08-AM 28-30B-F4 | |

| Cutting water pump motor | m/hm | 4-60 | |

| Accuracy | Positioning accuracy | mm | ±0.005 |

| Repeat positioning accuracy | mm | ±0.003 | |

| Power requirements | Power requirements | kv | 20 |

| Air source requirements | Kg/cm | 6~8 | |

| Machine size | Length*Width*Height | mm | 2800x2200x2900 |

| Weight | T | 5 |

Tags :