This product X, Y, Z three-axis servo direct control semi-closed vertical machining center, three-axis linear ball guide, guide rail load, span wide, high precision, suitable for heavy load, compact structure and size reasonable, the spindle is servo motor driven by the timing belt. It can realize the clamping of various parts such as discs, boards, housings, cams, and molds at one time. It can be used for drilling, milling, boring, expanding, reaming, rigid tapping, etc. The production of medium and small batch products can satisfy the processing of complex and high-precision parts. The fourth rotary shaft can be equipped to meet the processing requirements of special parts.

Max. X-axis Travel :

700mmMax. Y-axis Travel :

600mmMax. Z-axis Travel :

300mmMax Workpiece Length :

700mmMax Workpieces Width :

600mmMax Workpieces Weight :

400KGApplication :

Precision MoldProcessing :

Drilling, Milling, Tapping, EngravingStructural Characteristics of Engraving and Milling Machine

|

|

Engraving and Milling Machine Features

|

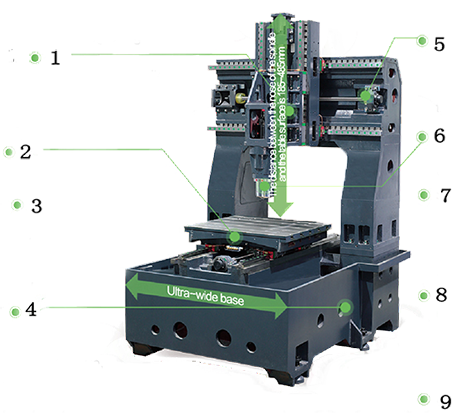

1. A patented spindle box of engraving and milling machine There is a stepped hole inside the spindle box; the electric spindle is installed in the stepped hole, and a flange is used to fix the spindle box 2. Worktable Box structure and ballscrew are integrally formed. 3. Optical linear scales Optional Heidenhain, Fagor optical linear scales with accuracy of under ±5um 4. Base Multi-layer wall box structure, rear chip extractions 5. A triangular rib structure of bridge column The utility model of the triangular rib structure of the door bridge improves the dynamic and static rigidity of the machine tool and enhances the processing accuracy. 6. Optional Direct-Driven BBT40 spindle 7. Upgrade Configuration Standard servo carousel tool magazine; HSK-E40 motor spindle; graphite protection package; laser tool probe; oil mist collector system, and more 8. Stable Accuracy The closed loop optical linear scales with high positioning accuracy can effectively suppress the positioning error caused by the thermal extension of the lead ballscrew. 9. System Stability Equipped with Siemens 828D system. |

|

Model |

YS-760B |

||

|

Subject |

Specifications |

Units |

|

|

Travel |

X/Y/Z axis |

mm |

700/600/300 |

|

Spindle Nose to Worktable |

mm |

225-525 |

|

|

Three-Axis Guideway |

/ |

Linear Guideway |

|

|

Door Width |

/ |

760 |

|

|

Worktable |

Worktable Size (L*W) |

mm |

700*600 |

|

Maximum Table Load |

kg |

400 |

|

|

T-Slot |

mm |

5-16x125 |

|

|

Spindle |

Spindle taper |

type |

ER32 |

|

Spindle speed |

rpm |

24000 |

|

|

Spindle Drive Type |

/ |

Built-In |

|

|

Feedrate |

Rapid Traverse (X/Y/Z) |

m/min |

15/15/12 |

|

Cutting Feedrate (X/Y/Z) |

m/min |

12 |

|

|

Tool Changer |

Tool Changer |

/ |

Carousel Servo ATC |

|

Motor |

Spindle Motor |

kw |

7.5 |

|

Three-Axis Servo Motor |

kw |

0.85/0.85/1.3 |

|

|

Accuracy |

Accuracy |

mm |

±0.005 |

|

Repeatability |

mm |

±0.003 |

|

|

Power Required |

Power Requirement |

kva |

12 |

|

Air Pressure Requirement |

kg/cm² |

6^8 |

|

|

Others |

External Dimensions (L*W*H) |

mm |

2100x2500x2550 |

|

Gross Weight |

t |

3.9 |

|

|

7.5KW-ER32-24000 Auto Tool Length Measurement Spindle Oil Cooler Fully Enclosure Guard |

Coolant Tank & Oil Skimmer Hand Wheel (MPG) Leveling Bolts and Pads Tool Box |

Automatic Lubricating System Transformer LED Work Light Spindle Air & Coolant Blast |

Transmission Software and Cables 20m LED 3 Color Warning Light Maintenance and Operational Manual Heat Exchange for Electric Cabinet |

Options

|

Oil Mist Collector ATC |

7.5KW-BT30-24000

|

BBT40-15000

|

Rotary Table

|

Tags :