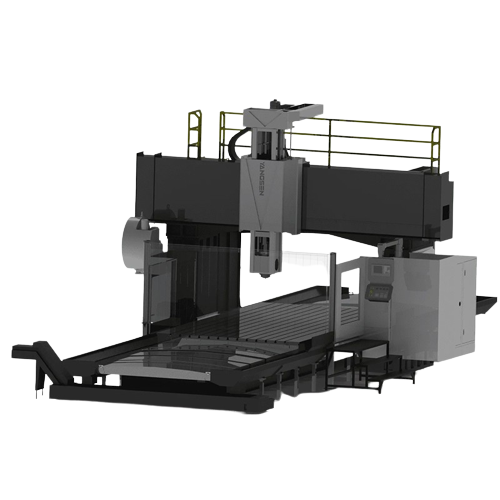

Heavy Cutting Double Column CNC Gantry Machining Center

The double-column machine adopts high rigid gantry frame structure and through two artificial aging treatments, has enough static and dynamic rigidity and good precision retention.

Max. X-axis Travel :

3000mmMax. Y-axis Travel :

2800mmMax. Z-axis Travel :

1000mmMax Workpiece Length :

3400mmMax Workpieces Width :

2200mmMax Workpieces Weight :

10TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingGantry Double Column Machine Description

For this series column and beam fixed double-column machining center, we adopt an international dynamic rigidity design idea and optimize the moving parts on the basis of high rigidity, structure symmetry, and high stability of traditional double-column machining center. This series of machines have the characteristic of high torque and fast feedback, which can meet the demand of auto, mold, aviation, and other mechanical machining fields. This series of machines are mainly made of a base, worktable, columns, beam, saddle, hydraulic system, lubrication system, cooling, and filtering system, chip device, CNC system, and other parts.

Gantry CNC Machine Structure Characteristics

|

|

① Square ram structure 500X500MM The machine installs a four-sided restraint quenching guide guideway and double-cylinder nitrogen balance device. The overall rigidity is strong. It has the strong cutting ability and stable precision.

② Italy BF gearbox High-performance speed, low noise, expandable motor constant power range with easy installation. It can be used in conjunction with multiple series of motors and adapt to high-strength tension.

③ Fully automatic side milling head The transmission gear is a Gleason spiral bevel gear. The transmission is stable and accurate. It has a long service life. The internal transmission key of the milling head is a quenched part with minimal backlash. |

Double-Column Machining Center Parameters

| Model | YSM-3028 | ||

| Subject | Specifications | Units | |

| Travel | X-Axis | mm | 3000 |

| Y-Axis | mm | 2800 | |

| Z-Axis | mm | 1000 (Optional 1250/1500) | |

| Spindle Nose to Worktable | mm | 350-1350 | |

| Three-Axis Guideway | X/Y Heavy Load Roller Linear Guideway Z-Axis Square-Type Ram | ||

| Door Width | 2800 | ||

| Type of Ram | Square-Type Ram (500x500) | ||

| Worktable | Worktable Size(L*W) | mm | 3400*2200 |

| Maximum Table Load | t | 10 | |

| T-Slot | mm | 11-28*200 | |

| Spindle | Spindle Type | type | BBT-50 |

| Spindle R.P.M. | rpm | 6000 | |

| Spindle Drive Type | DDS | ||

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 10/10/10 |

| Cutting Feedrate (X/Y/Z) | m/min | 8 | |

| Tool Changer | ATC | 24 (Option: 40/60) | |

| Motor | Spindle Motor | KW | 22/26 (140-286 Nm) |

| Three-Axis Servo Motor | KW | 6/3/3 (38/36/36 Nm) | |

| Accuracy | Accuracy | mm | 0.03/0.025/0.015 |

| Repeatability | mm | 0.02/0.02/0.01 | |

| Power Required | Power Requirement | kva | 45 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 8800*6050*5820(6320) |

| Gross Weight | t | 45 | |

Standard Accessories

|

Spindle Coolant System Automatic Lubricating System Semi-Enclosed Guard |

Rigid Tapping Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Dual LED Work Light LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

Geared Box Leveling Bolts and Pads M30 Auto Off |

Options

|

Optical Linear Scale CTS 20T/40T/60T ATC |

Workpieces Probe Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer |

Manual/Semi-Auto 90Milling Head Auto Parts Probe Measuring System |

Tags :