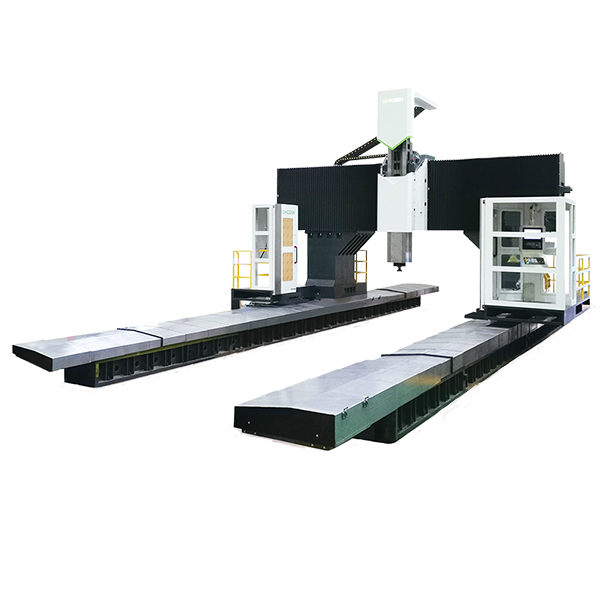

The movable column CNC machine tool can place larger workpieces and special-shaped workpieces on the table because the table does not move. Compared with the products with the same specification of the movable table structure, there is no need to worry that the workpiece will interfere with other parts of the machine tool.

Max. X-axis Travel :

18000mmMax. Y-axis Travel :

4200mmMax. Z-axis Travel :

1500mmMax Workpiece Length :

18000mmMax Workpieces Width :

3500mmMax Workpieces Weight :

50TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingDouble Column Machining Center Features

The gantry machining center adopts a moving column structure. When machining the workpiece, the worktable is fixed, and the X and Y axes of the workpiece are processed by the front and rear and left and right movements of the column, which solves the impact of the workpiece inertia on the machining center and overcomes the In order to avoid the generation of inertial errors, it is of great significance for machining heavy workpieces with high machining accuracy requirements.

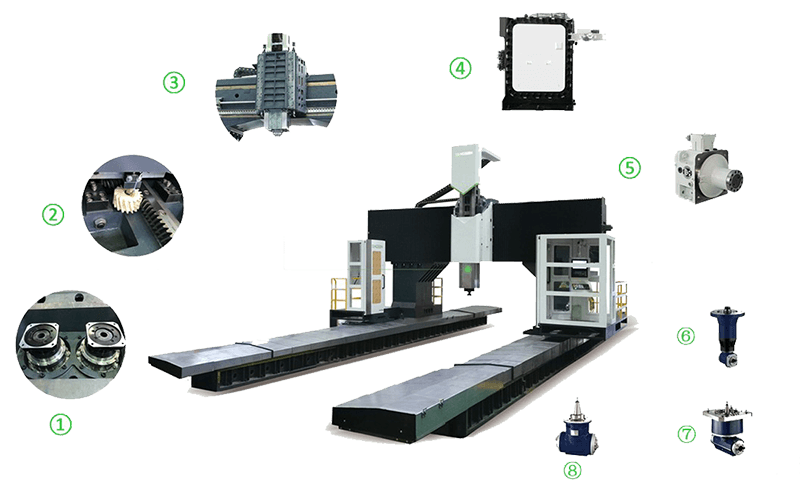

①. Dual Motor with Anti-Backlash Transmission Structure

High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life.

②. Gear Transmission

High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life.

③. Square Ram and Sliding Seat Structure

Dimension:500x500, Heavy-Duty Design;

Direct-Driven Design;

Large-Size and Heavy-Duty design ensures that the ram is firmly connected;

Three extended sliders at the top and four standard sliders at the bottom.

④. Vertical / Horizontal Automatic Tool Magazine

⑤. Italy BF Gear Box

High-performance speed, low noise. It could expand the motor's constant power range. It is easy to install. The machine can be used in conjunction with multiple series of motors. It can adapt to high-strength tension and small size.

⑥. Extended Angle Milling Head

⑦. Automatic Hydraulic Angle Milling Head

⑧. Two-Way Spindle Angle Milling Head

Moving Column Series Parameters

| Model | YSMD-18042 | ||

| Subject | Specifications | Units | |

| Travel | X-Axis | mm | 18000 |

| Y-Axis | mm | 4200 | |

| Z-Axis | mm | 1500 | |

| Spindle Nose to Worktable | mm | 350-1850 | |

| Three-Axis Guideway | X/Y Heavy Load Roller Linear Guideway Z-Axis Square-Type Ram | ||

| Door Width | 4200 | ||

| Type of Ram | Square-Type Ram (500 * 500) | ||

| Worktable | Worktable Size(L*W) | mm | 18000*3500 |

| Maximum Table Load | t | 50 | |

| T-Slot | mm | 36*200 | |

| Spindle | Spindle Type | type | BBT-50 |

| Spindle R.P.M. | rpm | 6000 | |

| Spindle Drive Type | DDS | ||

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 6/8/8 |

| Cutting Feedrate (X/Y/Z) | m/min | 6 | |

| Tool Changer | ATC | 24 (Option: 40/60) | |

| Motor | Spindle Motor | KW | 17-42 |

| Three-Axis Servo Motor | KW | 5.2/5.2/5.2 | |

| Accuracy | Accuracy | mm | 0.09/0.035/0.02 |

| Repeatability | mm | 0.075/0.025/0.015 | |

| Power Required | Power Requirement | kva | 60 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 22000x5860x5800 |

| Gross Weight | t | 155 | |

Standard Accessories

|

Spindle Coolant System Automatic Lubricating System Semi-Enclosed Guard |

Rigid Tapping Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Dual LED Work Light LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

Geared Box Leveling Bolts and Pads M30 Auto Off |

Options

|

Optical Linear Scale CTS 20T/40T/60T ATC |

Workpieces Probe Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer |

Manual/Semi-Auto 90Milling Head Auto Parts Probe Measuring System |

Tags :