Gantry Machining Center Double-Column Heavy-Duty Turning/Milling/Grinding/Cutting/Drilling Hardware Machining Center

A Gantry machining center machine tool, suitable for machining equipment for various large workpieces in shipbuilding, power generation, construction machinery, locomotives, machine tools, textile machinery, printing machinery, molds, and other industries. The high-strength, high-rigidity design of the machine tool and the structure of the large-flow discharge channel has the characteristics of high precision, high efficiency, flexibility, and environmental protection.

Max. X-axis Travel :

2000mmMax. Y-axis Travel :

1300mmMax. Z-axis Travel :

800mmMax Workpiece Length :

2000mmMax Workpieces Width :

1000mmMax Workpieces Weight :

3TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingDouble Column Machining Center Structure Characteristics

The double-column machining center has strong rigidity, a symmetrical structure, and high stability. Through continuous optimization of the component structure, the dynamic performance of the product is improved, and high-power, high-torque, high-efficiency, and high-precision machining are realized. It is suitable for large-scale processing fields such as shipbuilding, metallurgy, mining machinery, power energy, construction machinery, heavy industry machinery, and more.

|

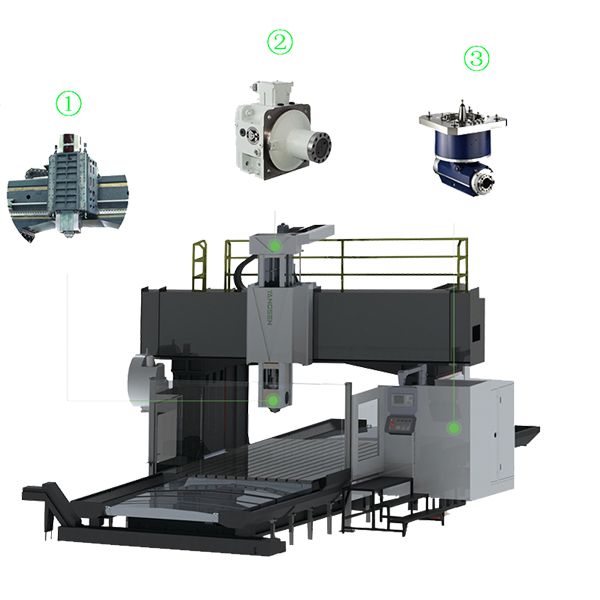

① Square ram structure 500X500MM The machine installs a four-sided restraint quenching guide guideway and double-cylinder nitrogen balance device. The overall rigidity is strong. It has the strong cutting ability and stable precision.

② Italy BF gearbox High-performance speed, low noise, expandable motor constant power range with easy installation. It can be used in conjunction with multiple series of motors and adapt to high-strength tension.

③ Fully automatic side milling head The transmission gear is a Gleason spiral bevel gear. The transmission is stable and accurate. It has a long service life. The internal transmission key of the milling head is a quenched part with minimal backlash. |

|

|

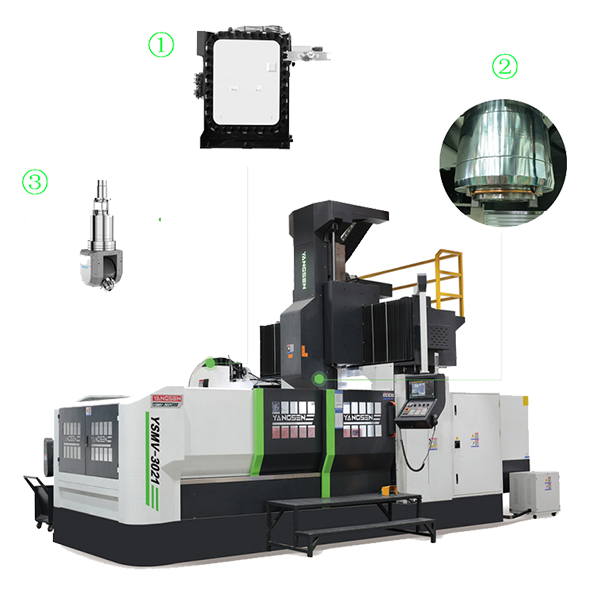

① Vertical and horizontal tool magazine

② Spindle Using BBT50- © 200 high rigidity spindle, 6 imported large steel ball bearings, super cutting ability.

③ Five-axis linkage double swing milling head AC axis torque motor + electric spindle fork-shaped integrated structure; AC axis installs torque motor structure; AC axis hydraulic holding for high-speed cutting and high rigidity. |

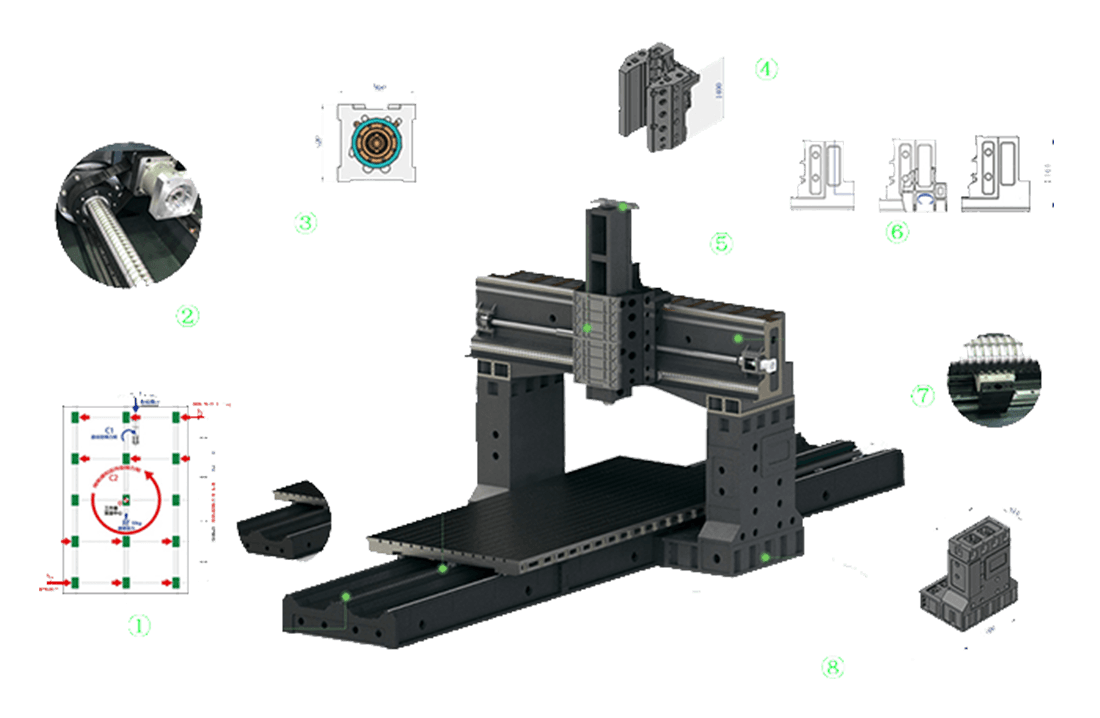

① Base structure

Compared with the double-guideway design, the rigidity is 50% higher;

Compared with the four-guide ways design, it is more symmetrical and evenly distributed, reducing the power loss caused by the resistance of the multi-guideway slider;

3m wide worktable, 2.1m base linear guideway. It is best ratio span of 0.7.

② Gantry moving nut structure

The X-axis is driven by a moving nut, and three-point support is used in the middle to maintain the rotation accuracy of the ball screw rod. At the same time, the load capacity is large, and the cutting vibration resistance is good. It can improve the dynamic characteristics of the machine tool and increase the accuracy, stability, and service life of the machine tool.

③ Square ram

Bigger dimensions 500*500, the original size is 460*460. It is a more heavy-duty design;

The built-in direct connection design reduces the power transmission consumption from the spindle motor to the spindle.

④ Slide features

The large-size and heavy-duty design ensure that the upper part of the ram is firmly hugged by the three elongated sliders, and the lower part is supported by the four standard sliders.

⑤ Nitrogen counterweight

Reduce the load of the motor and the bearing force of the ballscrew, increase the life of the ballscrew and the motor, and the acceleration of the Z axis to ensure processing accuracy.

⑥ Beam structure

Stepped L-shaped design improves rigidity;

The concave C-shaped structure has better bending resistance;

Large section design;

Finite element analysis.

⑦ Ballscrew support frame system

⑧Column structure

The 1.28m ultra-wide design of the column reduces the overall cutting vibration and makes the machine tool stable.

Double-Column Machining Center Parameters

|

Model |

YSM-2013 |

||

|

Subject |

Specifications |

Units |

|

|

Travel

|

X-Axis |

mm |

2000 |

|

Y-Axis |

mm |

1300 |

|

|

Z-Axis |

mm |

800 |

|

|

Spindle Nose to Worktable |

mm |

190-990 |

|

|

Three-Axis Guideway |

|

X/Y Heavy Load Roller Linear Guideway Z-Axis T-Type Ram Box Way |

|

|

Door Width |

|

1300 |

|

|

Worktable |

Worktable Size(L*W) |

mm |

2000*1000 |

|

Maximum Table Load |

t |

3 |

|

|

T-Slot |

mm |

7-22*150 |

|

|

Spindle |

Spindle Type |

type |

BBT-50 |

|

Spindle R.P.M. |

rpm |

6000 |

|

|

Spindle Drive Type |

|

Belt (DDS/Geared) |

|

|

Feedrate |

Rapid Traverse (X/Y/Z) |

m/min |

12/12/12 |

|

Cutting Feedrate (X/Y/Z) |

m/min |

10 |

|

|

Tool Changer |

ATC |

|

24 (Option: 40/60) |

|

Motor |

Spindle Motor |

KW |

15/18.5 (143-236 Nm) |

|

Three-Axis Servo Motor |

KW |

3/3/3 (36 Nm) |

|

|

Accuracy |

Accuracy |

mm |

0.03/0.02/0.015 |

|

Repeatability |

mm |

0.02/0.015/0.01 |

|

|

Power Required |

Power Requirement |

kva |

40 |

|

Air Pressure Requirement |

kg/cm² |

6^8 |

|

|

Others |

External Dimensions (L*W*H) |

mm |

6300*4480*4100 |

|

Gross Weight |

t |

18.5 |

|

Standard Accessories

|

Rigid Tapping Automatic Lubricating System Semi-Enclosed Guard |

Dual LED Work Light Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Spindle Nose Air Blow LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

M30 Auto Off Leveling Bolts and Pads |

Options

|

Optical Linear Scale CTS 40T ATC |

Tool Breakage System Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer 90° Manual Milling Head |

Air Conditioner Auto Parts Probe Measuring System 90° Auto Milling Head with AHC |

Tags :