Today, in modern machining, precision and efficiency are key to success. When it comes to creating deep slots, shoulders, or complex profiles, choosing the right cutting tool is crucial, and this is exactly where side and face milling cutters excel.

These cutters are uniquely designed to remove material from both the side and face of a workpiece in a single operation, making them ideal for heavy-duty and high-accuracy milling tasks. They’re widely used for slotting, parting, and surface finishing, offering improved dimensional accuracy and time savings.

With the evolution of insert technology, side and face milling cutters now deliver longer tool life, smoother finishes, and reduced operational costs.

In this guide, we’ll explore what side and face milling cutters are, how insert types affect their performance, and why selecting the right cutter is key to achieving consistent, cost-effective machining results.

Side and face milling cutters are designed to handle demanding machining tasks that require both lateral (side) and axial (face) material removal. Their design allows them to perform two cutting actions in one pass, improving machining efficiency, accuracy, and productivity. To understand how these cutters operate effectively, it’s important to explore their construction, working principle, and applications across various materials.

The structure of a side and face milling cutter is engineered for strength, balance, and precise cutting. Each component plays a vital role in achieving smooth, stable, and efficient performance:

Cutter Body

The main body of the tool is typically made from high-strength alloy steel or other durable materials. It provides the base for holding inserts and ensures rigidity to resist deflection during heavy cutting.

Insert Pockets

Around the periphery and side faces of the cutter are carefully machined pockets designed to hold inserts. These pockets maintain insert alignment and positioning, ensuring consistent cutting geometry.

Clamping Systems

Inserts are secured using clamping mechanisms such as screws, wedges, or clamps. A reliable clamping system prevents insert movement during cutting and allows for quick replacement when an insert becomes worn.

Coolant Channels

Many modern side and face milling cutters are equipped with internal coolant channels. These channels direct cutting fluid precisely toward the cutting zone, helping to dissipate heat, improve chip evacuation, and extend tool life.

Together, these components make the cutter durable, adaptable, and capable of withstanding the forces encountered in high-load machining.

The working principle of a side and face milling cutter revolves around simultaneous material removal from the workpiece’s face and side surfaces. Unlike standard milling cutters that engage with only one direction at a time, these tools are designed for dual engagement.

When the cutter rotates:

• The peripheral inserts remove material from the side of the workpiece.

• The side-mounted inserts simultaneously cut across the face.

This combination allows for efficient metal removal and reduces the need for multiple passes. The approach is especially beneficial in:

• Slotting and parting operations where deep and precise cuts are required.

• Heavy-duty machining, as the tool distributes cutting forces evenly.

• Time-sensitive production where fewer tool changes and setups improve productivity.

The main advantages of this working principle include:

• Higher material removal rates

• Reduced machining time

• Improved dimensional accuracy

• Enhanced surface finish with fewer tool marks

By integrating face and side cutting into a single operation, side and face milling cutters help manufacturers achieve consistent results even under demanding conditions.

Side and face milling cutters are versatile tools suitable for a wide range of materials used in modern manufacturing. Their adaptability depends on insert type, geometry, and coating, which can be optimized for each material type.

Steels and Alloy Steels

Common in automotive and heavy machinery industries, these materials require tough inserts capable of withstanding high cutting forces and temperatures. Carbide or coated inserts are typically used for the best performance.

Aluminum and Non-Ferrous Metals

Lightweight materials such as aluminum need sharp-edged, positive rake inserts to prevent built-up edges and achieve smooth finishes. High-speed cutting with minimal vibration is ideal.

Cast Iron

Due to its brittle nature, cast iron benefits from strong, negative-rake inserts that maintain edge stability. These cutters handle intermittent cuts well and produce consistent surface quality.

Stainless Steel and Heat-Resistant Alloys

These materials generate significant heat during cutting, so inserts with heat-resistant coatings (like TiAlN or AlCrN) are used to prevent wear and maintain tool life.

The flexibility of side and face milling cutters across multiple materials makes them a reliable choice for both general machining and specialized manufacturing applications.

The performance of a side and face milling cutter largely depends on the type of inserts it uses. Inserts determine how efficiently the cutter removes material, the quality of the finished surface, and how long the tool lasts before needing replacement. Understanding different insert types helps machinists select the most suitable option for specific tasks and materials.

Indexable inserts are replaceable cutting tips that can be rotated or flipped once an edge becomes dull. Instead of replacing the entire tool, the worn insert can be indexed to expose a fresh edge, saving both time and cost.

Key advantages include:

• Cost efficiency: Only the inserts need replacement, not the cutter body.

• Reduced downtime: Quick insert changes without resetting tool positions.

• Versatility: Various insert geometries and coatings can be used for different materials.

Because of these benefits, indexable inserts are widely used in side and face milling cutters, especially in high-volume or continuous production environments.

Insert geometry is another important factor in determining performance. The two main types, positive and negative inserts, each have unique strengths.

Positive Inserts

• Feature a sharp cutting edge with a positive rake angle.

• Require less cutting force and produce smoother finishes.

• Best suited for light to medium finishing operations and softer materials like aluminum or mild steel.

Negative Inserts

• Have a strong, blunt edge with a negative rake angle.

• Withstand higher cutting loads and are more durable.

• Ideal for roughing and heavy-duty cutting of tough materials such as cast iron or hardened steel.

Choosing between these geometries depends on the type of operation, finishing, semi-finishing, or roughing, and the workpiece material.

Coatings and carbide grades play a critical role in improving insert performance and longevity. Modern inserts use advanced coatings that enhance wear resistance, reduce friction, and allow higher cutting speeds.

Common coating technologies include:

• PVD (Physical Vapor Deposition): Produces thin, hard coatings suitable for sharp-edged tools and fine finishing. Examples: TiAlN, AlTiN.

• CVD (Chemical Vapor Deposition): Creates thicker, more durable coatings for heavy cutting and roughing operations. Examples: TiC, TiCN, Al₂O₃.

Carbide Grades

Different carbide compositions are optimized for specific applications.

• Hard grades resist wear for high-speed finishing.

• Tough grades endure impact and vibration in roughing or interrupted cuts.

Selecting the right combination of coating and grade ensures balanced performance between durability, speed, and surface quality.

Selecting the most suitable insert involves considering several practical factors. The right choice ensures better cutting efficiency, extended tool life, and optimal surface quality.

Key factors to consider:

• Material type: Hard materials require strong, coated inserts; softer materials benefit from sharp, positive geometries.

• Cutting conditions: For high-speed cutting, use wear-resistant coatings; for interrupted cuts, use tougher inserts.

• Depth of cut and feed rate: Larger depths or higher feeds demand negative inserts with stronger edges.

• Machine stability: Rigid machines can handle heavy-duty inserts, while less rigid setups require lighter cutting loads.

A carefully selected insert type not only enhances performance but also minimizes downtime and tool replacement costs, which ensures a balanced mix of productivity, precision, and profitability in milling operations.

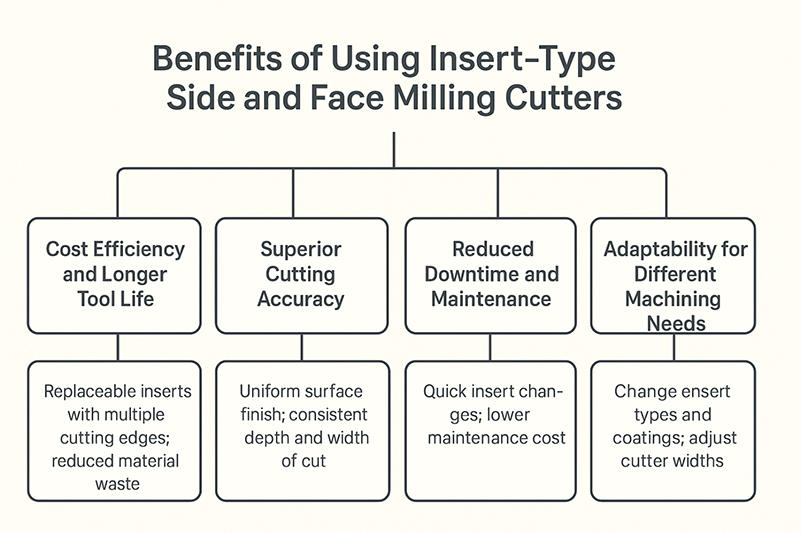

Insert-type side and face milling cutters have become a preferred choice in both small-scale and large-scale machining operations due to their exceptional performance, flexibility, and cost-effectiveness. Unlike traditional solid cutters, these tools use replaceable inserts that can be easily indexed or swapped when worn out. This design not only simplifies maintenance but also ensures consistent cutting performance over long periods.

Below are the key benefits that make insert-type side and face milling cutters an essential tool in modern manufacturing.

One of the biggest advantages of insert-type cutters is their cost efficiency. Instead of replacing the entire cutter when it becomes dull, only the individual inserts need to be changed. This approach greatly reduces the overall tooling cost, especially in production environments where cutters experience frequent wear.

Here’s why they are more economical:

• Replaceable inserts: Only the worn inserts are replaced, while the cutter body remains in use for a long time.

• Multiple cutting edges: Most inserts have multiple usable edges, allowing them to be indexed several times before full replacement.

• Reduced material waste: Unlike solid cutters that require complete regrinding or replacement, inserts minimize material consumption.

In addition, inserts are available in a variety of grades and coatings designed to resist wear and heat, extending tool life even further. This combination of durability and cost-saving makes them ideal for continuous, high-volume operations.

Precision is a critical requirement in machining, especially for parts that demand tight tolerances and smooth surface finishes. Insert-type side and face milling cutters excel in providing consistent and accurate cuts because of their engineered geometry and stable clamping systems.

Each insert is manufactured with high dimensional accuracy, ensuring a uniform cutting edge along the entire periphery of the cutter. This precision results in:

• Uniform surface finish across the machined area.

• Consistent depth and width of cut during repetitive operations.

• Improved dimensional control, reducing the need for secondary finishing or manual corrections.

Moreover, insert clamping systems are designed to maintain perfect positioning, preventing movement during operation. This stability ensures the tool can handle both heavy and fine cutting without compromising on accuracy or repeatability.

In modern manufacturing, minimizing machine downtime directly translates into higher productivity. Insert-type side and face milling cutters are specifically designed to make tool changes fast and efficient, significantly reducing setup and maintenance time.

When an insert wears out, operators can quickly index it to a new edge or replace it without removing the entire cutter from the machine spindle. This simple process eliminates the need for lengthy realignment or retooling procedures.

Benefits include:

• Faster insert changes with minimal disruption to production.

• Reduced machine idle time.

• Lower maintenance and inventory costs, since only inserts are stocked rather than full cutters.

These cutters are especially useful in automated machining lines, where every minute saved in tool changeover contributes to higher throughput and consistent workflow.

Another standout feature of insert-type side and face milling cutters is their adaptability. Machining conditions often vary depending on the workpiece material, cutting speed, and desired finish, and these cutters are built to adjust easily to such variations.

Operators can change insert types, coatings, or even cutter widths to suit specific applications. For instance:

• Switching from positive-rake inserts for aluminum to negative-rake inserts for cast iron.

• Using coated carbide inserts for high-speed cutting of steel and stainless steel.

• Adjusting the cutter width to perform shallow or deep slotting depending on the job requirement.

This flexibility not only allows a single cutter body to handle a variety of materials but also reduces the need for maintaining multiple tool types. As a result, manufacturers can optimize tool usage, save on storage space, and respond quickly to different machining tasks without major setup changes.

In modern machining, choosing the right cutting tool can significantly affect productivity, surface quality, and overall operating costs. Among the most widely used tools are insert-type and solid-type milling cutters, each designed for specific machining needs. However, as manufacturing technology evolves, insert-type milling cutters have become the preferred option for most industrial applications due to their superior efficiency, cost control, and versatility.

Let’s explore how these two tool types differ, with a focus on why insert-type cutters are increasingly dominating today’s production environments.

The performance gap between insert-type and solid-type cutters becomes most evident in terms of efficiency, durability, and flexibility.

Insert-Type Milling Cutters

These cutters are built for high-performance and continuous machining operations. They feature indexable inserts, replaceable cutting tips mounted onto a robust cutter body, which can handle both roughing and finishing tasks efficiently.

Key performance advantages include:

• Consistent cutting quality: Inserts maintain uniform cutting geometry, providing consistent results over long runs.

• Higher material removal rates: Designed to take deeper cuts and operate at higher feed speeds without compromising stability.

• Versatile insert options: Users can choose from different insert shapes, rake angles, and coatings to match specific materials such as steel, cast iron, or aluminum.

• Optimized heat control: Advanced insert coatings like TiAlN or AlCrN help manage heat during high-speed cutting, preventing tool damage.

These advantages allow insert-type cutters to excel in heavy-duty, multi-material, and high-volume operations that make them ideal for industries like automotive, aerospace, and general manufacturing.

Solid-Type Milling Cutters

Solid-type milling cutters, on the other hand, are best suited for small-scale or precision operations. While they provide rigidity and excellent balance, they cannot match the speed and adaptability of insert-type cutters. Once worn, solid cutters need complete regrinding or replacement, leading to higher costs and downtime in large production setups.

In short, when it comes to balancing productivity and efficiency, insert-type cutters outperform solid-type tools in nearly every production environment.

Maintenance is another area where insert-type milling cutters clearly stand out. Their modular design with replaceable inserts dramatically simplifies tool management.

When a cutting edge becomes dull or chipped, the operator can simply:

• Rotate the insert to a fresh edge (indexing), or

• Replace the individual insert with a new one.

This entire process takes only minutes; no need to remove the cutter body or reset the tool. The machine remains in operation with minimal interruption, ensuring continuous production flow.

Additional maintenance advantages include:

• Lower tooling costs: The cutter body is reused for years, reducing the expense of purchasing complete tools repeatedly.

• Reduced calibration time: Since the cutter body remains mounted, there’s no need for tool re-alignment after insert changes.

• Easier inventory management: Only inserts need to be stocked in various grades and geometries, not full cutters.

In contrast, solid-type cutters require more effort and expense. Once the cutting edges wear out, the entire cutter must be re-sharpened or replaced. This leads to:

• Frequent tool changes.

• Longer setup times.

• Potential loss of dimensional accuracy after multiple regrinds.

This difference in maintenance directly affects uptime and production efficiency, and is one of the main reasons why insert-type cutters are preferred for modern CNC machining environments where time equals money.

While both cutter types have their place, insert-type side and face milling cutters offer a much broader range of benefits for today’s machining demands.

Choose Insert-Type Milling Cutters If You Want:

• Higher Productivity: They support faster cutting speeds and deeper cuts, allowing more material removal in less time.

• Cost Efficiency: Only inserts are replaced, not the entire tool, which lowers long-term tooling costs.

• Operational Flexibility: You can easily adapt to different materials by changing insert grades, geometries, or coatings.

• Extended Tool Life: Coated inserts and strong cutter bodies withstand heat and wear better than solid tools.

• Minimal Downtime: Quick insert indexing means less machine stoppage and higher output consistency.

Solid-Type Cutters May Be Preferred When:

• The application involves precision finishing or tight-tolerance micro-machining.

• The machine setup does not require frequent tool changes.

• The budget allows for specialized cutters for specific one-time jobs.

However, for most production-scale operations, the advantages of insert-type cutters are undeniable. Their combination of replaceable inserts, robust cutter bodies, and adaptability to multiple materials makes them a long-term, cost-effective investment.

They not only reduce waste and downtime but also help maintain consistent quality across large batches, something solid-type cutters struggle to achieve efficiently.

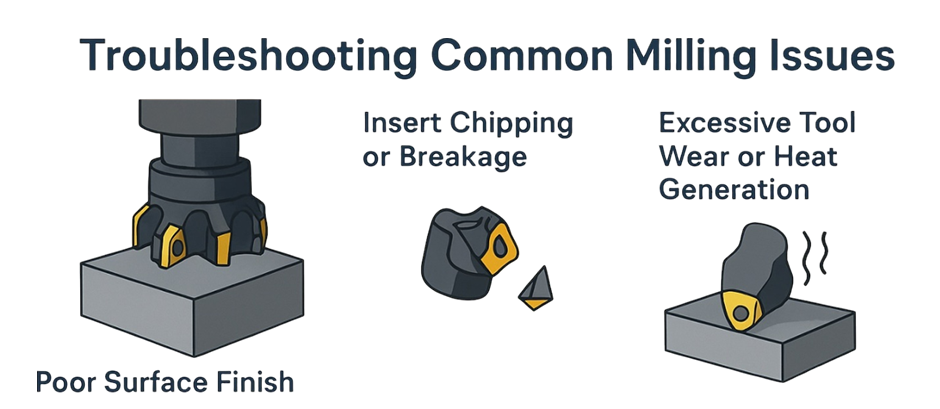

Even with high-quality side and face milling cutters, operators can sometimes face challenges such as poor surface finish, insert chipping, or rapid tool wear. Understanding these issues and their root causes is essential for maintaining consistent performance and avoiding downtime. Here are some of the most common problems encountered during milling operations, and how to solve them effectively.

A poor surface finish is one of the most frequent issues in milling, often resulting in rough textures, visible tool marks, or uneven patterns on the workpiece.

Common Causes:

• Worn or damaged inserts

• Incorrect feed rate or cutting speed

• Excessive vibration or chatter

• Misalignment of the cutter or workpiece

• Inadequate coolant flow

Solutions:

• Regularly inspect and replace dull or chipped inserts.

• Adjust feed and speed according to the workpiece material, typically, reducing speed or increasing feed can improve the surface finish.

• Ensure the cutter is securely mounted and check for runout or imbalance.

• Use proper coolant or lubrication to minimize heat and prevent built-up edges.

• Consider using a positive rake insert for smoother cutting, especially during finishing operations.

A consistent surface finish not only enhances the product’s appearance but also improves its mechanical properties and dimensional accuracy.

Insert chipping or sudden breakage can disrupt production and cause damage to both the cutter and the workpiece. This usually happens due to mechanical shock, thermal stress, or improper cutting parameters.

Typical Causes:

• Excessive feed rate or depth of cut

• Interrupted cutting (e.g., milling across keyways or uneven surfaces)

• Incorrect insert geometry for the application

• Improper clamping or loose screws

• Using a brittle insert grade for hard materials

Preventive Measures:

• Reduce feed and depth of cut to lower impact loads.

• Choose a tougher insert grade or use a negative rake insert for heavy-duty cutting.

• Ensure inserts are firmly clamped and properly seated in clean pockets.

• Avoid dry cutting in high-temperature conditions, use coolant to reduce thermal shock.

• When cutting interrupted surfaces, slow down spindle speed to minimize mechanical stress.

Regular monitoring of the insert condition helps prevent catastrophic failures and ensures stable tool life.

Excessive wear or overheating can quickly reduce the efficiency of milling operations, leading to dimensional inaccuracies, rough surfaces, and shortened tool life.

Common Reasons:

• Cutting speed too high for the material or insert grade

• Inadequate cooling or lubrication

• Incorrect coating or insert material selection

• Continuous operation without proper maintenance intervals

Solutions and Tips:

• Optimize cutting parameters by lowering cutting speed or increasing feed per tooth slightly to reduce friction.

• Use coated inserts (such as TiAlN or AlTiN) to improve heat resistance and wear protection.

• Apply coolant or air blast effectively to maintain ideal cutting temperatures.

• Avoid prolonged cutting without breaks; periodic checks allow heat to dissipate naturally.

• Ensure the cutter body and inserts are cleaned regularly to prevent built-up edges.

Balancing cutting parameters with proper insert selection and cooling practices can drastically enhance tool performance and reliability.

Precision milling is all about balance, between speed and control, efficiency and durability. You can use insert-type side and face milling cutters correctly to ensure smoother operations, improved productivity, and cost savings over time. When maintained and operated using proper techniques, these tools can deliver consistent, high-quality results across a wide range of materials.

To summarize, the success of side and face milling operations depends on a combination of the right cutter design, insert type, and operating practices.

Here’s what to remember:

• Choose inserts based on the material and type of operation (roughing or finishing).

• Maintain correct cutter alignment and clamping to prevent vibration and uneven wear.

• Regularly inspect inserts for wear and replace or index them on time.

• Adjust cutting speeds, feeds, and depth according to the material to avoid heat buildup.

• Always prioritize safety and coolant management for consistent performance.

By following these principles, manufacturers can achieve higher precision, better surface finishes, and extended tool life.

Recommendation & Next Steps

If you’re aiming to improve machining accuracy, extend tool life, and reduce overall production costs, investing in a high-quality insert-type side and face milling cutter is the right step forward. Modern cutters with indexable inserts are designed for adaptability, allowing quick insert changes and superior surface results in both light and heavy-duty applications.

Whether you work with steel, aluminum, or cast iron, choosing the right insert geometry, coating, and grade can transform your milling performance. Consider exploring advanced insert-type cutter solutions offered by reputable manufacturers to achieve optimal efficiency and precision in your next machining project.