Precision, power, and performance are the three crucial factors required to cut aluminum. Among the numerous available solutions, the CNC router machine for aluminum is the most efficient, accurate, and cost-effective. Delivering complex designs, smooth finishing effects, and fast cutting speeds. It has become a pillar of modern metalworking and manufacturing industries.

We are committed to delivering high-performance CNC routers specifically made for aluminium and non-ferrous metal applications. We enable all our customers to achieve maximum productivity and accuracy.

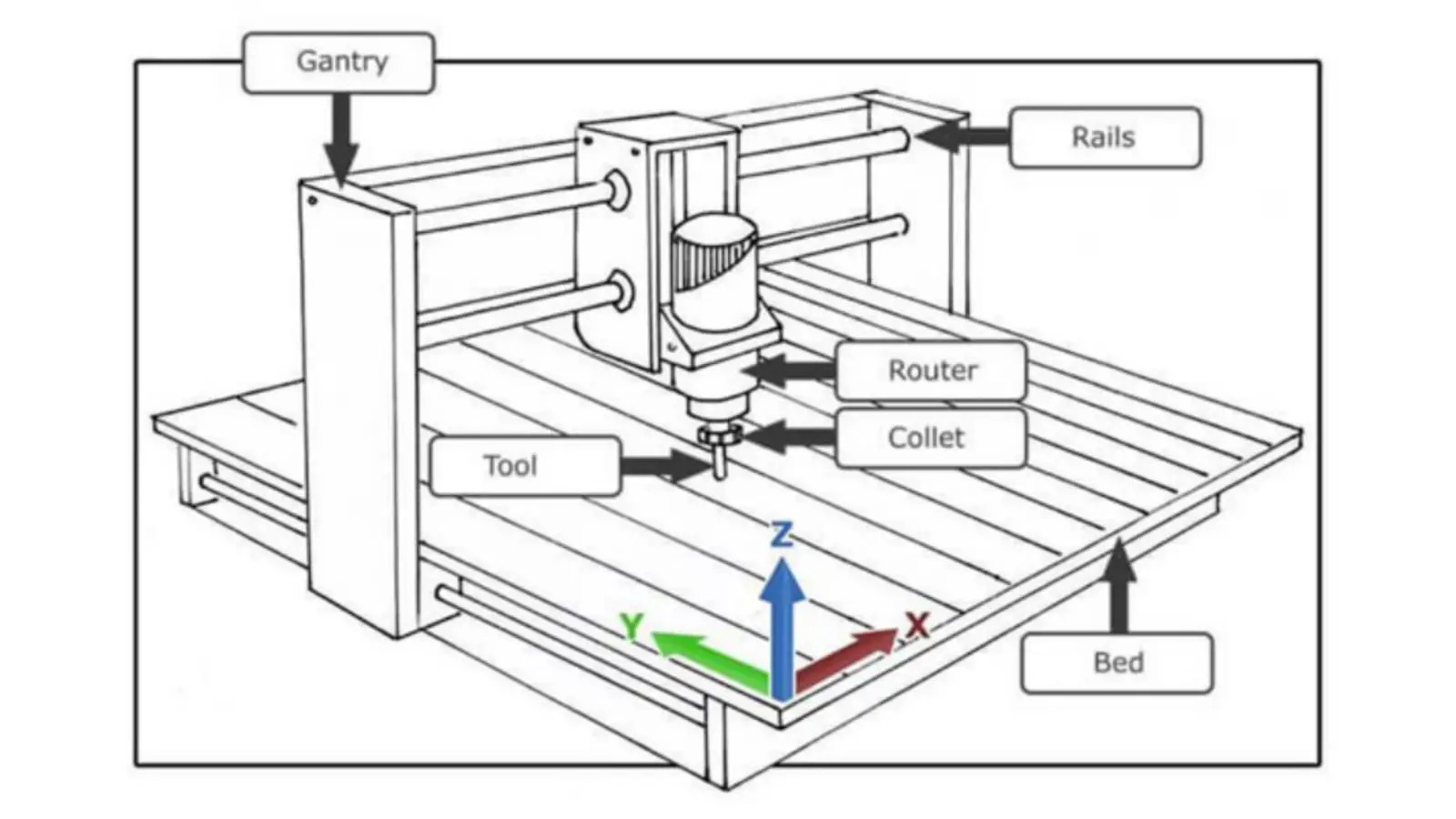

A CNC router machine for aluminum refers to a computer-controlled cutting system. Shapes, engravings, or drills can carve aluminum sheets and components within very tight tolerances. In contrast to using a manual machine, all commands cause the spindle to move. The setting depth for cutting is programmed through G-code control.

A router works with high-speed rotating tools or bits to cut into aluminum surfaces. It produces uniform, reproducible parts for applications from aerospace to signage fabrication.

Our aluminum CNC routers have a rigid machine frame with a high-speed spindle. Our advanced motion control systems can even process aluminum plates, molds. On the other hand, extruded components ensure the repeatability and surface quality.

Critical components identify how smoothly an aluminum cordless cutter operates, offering both precision and right machining. Here are a few components of an aluminum CNC router as given below:

The spindle is considered the heart of every CNC router for aluminum. A high-speed spindle operates normally at 24,000 revolutions per minute and above. It guarantees a perfect, smooth, and accurate touch even on tough aluminum surfaces when cutting. A steady spindle minimizes chatter and vibrations, thereby improving surface finish and tool life.

The precision during motion has an important role in the drive system. Connected to ball screws, it made a linear guide rail system indirectly. The stable motion transmission and backlash elimination are all important in machining aluminum at high speeds.

Well-designed drive system gives smooth transitions, better dimensional accuracy, and longer mechanical endurance of the entire CNC router.

The control system is the brain of a CNC router. These advanced CNC controllers can process very complicated toolpaths. It ensures that every cut stays on the course of its programmed trajectory.

The system provides real-time feedback and adaptive control features. It automatically adjusts feed rates plus spindle speeds in order to achieve optimum cutting quality and production flows.

Aluminum has very good thermal conductivity, and therefore heats immediately when machining. Cooling systems with mist or air would keep both cutting tools and workpieces in a favorable temperature setting.

A robust and steady worktable provides solid grounding for accurate machining. Vacuum or T-slot tables are used for fixing workpieces by CNC routers for aluminum. It would cause vibration with the respective loss of cutting precision and overall quality of the part. Especially in the case of thinner aluminum sheets.

When machining aluminum, efficient chip extraction becomes vital. Powerful dust and chip removal systems prevent debris buildup. Also tends to degrade tool performance and cutting accuracy in the process. Clean machining areas lengthen the life of machine components while ensuring a safe and efficient working atmosphere.

The routers combine all these components in a compact, rigid structure, optimized for long-term consistency and accurate cutting.

Superior Accuracy CNC Router Machines for Aluminum cut with incredibly high accuracy. Every cut is made using computer-controlled programming. Each follows a preset digital path down to the microns. All parts are produced identically to the design, despite of how many copies are made.

One of the strongest advantages of using a CNC router for aluminum cutting is its high-quality production speed. Once the digital design and toolpath are set, the machine can continuously process multiple sheets without interruption. Automation significantly reduces setup and machining times, helping manufacturers meet high-volume demands efficiently.

CNC routers can create shapes that would be impossible or extremely difficult to produce manually. From 3D contours, deep pockets to engraved text and fine detailing, these machines can execute complex toolpaths with outstanding accuracy.

This makes them ideal for projects involving molds, signage, and artistic aluminum designs. The digital nature of CNC routing allows seamless transitions between different shapes, patterns, and depths, enabling endless design possibilities.

Aluminum is a delicate material that can easily show tool marks or rough edges if not cut correctly. CNC routers solve this issue with advanced feed rate control and vibration reduction technology. The result is a smooth, polished surface straight off the machine. This technique minimizes the need for additional finishing or polishing.

Using optimized toolpaths generated through CAM software, CNC routers utilize a maximum amount of material with each movement calculated to use as little raw aluminum as possible to produce the desired shape. It includes reducing waste and costs while buying the raw material, which is important because aluminum provides high value. Additionally, an accurate nesting of parts within each sheet attests to the layout efficiency and sustainability of production.

Another major factor is that CNC routers are really flexible. Different aluminum alloys with varying thicknesses can be processed, making it appropriate for many project sizes. One can rapidly change a design, or perhaps even change a setting, without modifying anything set on the machine. This way, a workshop can manage a line of prototypes-to-full-scale production runs without sacrificing any precision or speed.

Once machine programming and proper setup are done, routers save a lot on manual labor. Most of the major cutting, drilling, or engraving processes are done by automated operation, and human involvement is minimised. Hence, even a single operator can monitor many machines simultaneously, which reduces costs significantly.

Even experienced machinists face certain challenges when cutting aluminum with CNC routers:

|

Challenge |

Cause |

Solution |

|

Chip welding on tools |

Pay attention to the heat generated |

Mist-cool, use high-polish bits. |

|

Poor surface finish |

Incorrect feed or dull bit |

Change the cutting parameters and/or bits. |

|

Vibration marks |

Weak clamping |

Use vacuum holding or T-slot hold-downs. |

|

Tool breakage |

Excessive cutting depth |

Reduce the depth of cut and increase the feed speed. |

The routers are furnished with anti-vibration devices, smart control systems, and cooling systems to help technicians mitigate these issues.

Cutting tool selection for CNC routers is very important for aluminum machining. Solid carbide end mills of 1 or 2 flutes are the best options for aluminum working. It gives them wear resistance and good cutting characteristics. Polished flute geometry is best for smoother cutting and has an effective way of displacing chips away from cuts.

For a better lifetime, diamond-coated bits will survive heavy aluminum cutting applications. The feed rate should be maintained at 300-600 mm/min with spindle speeds between 15000-24000 RPM for the finest results. An additional mist-cooling or lubrication system that prevents aluminum from sticking to the bit. It greatly reduces heat generation and enhances these worthwhile tools.

We offer a customizable tool. The spindle configurations are designed to meet the specific needs of your aluminum cutting, with reliable and efficient performance.

Aluminum CNC routing finds applications in several industries, ranging from aerospace, automotive, and signage to construction, furniture, and interior design, and electronics.

The possibilities for aluminum CNC routing become a major asset in so many industries:

• Aerospace: Aircraft panels, brackets, and interior finishes.

• Automotive: Engine components, dashboards, and trims.

• Signage: 3D letters, logos, and custom display panels.

• Construction: Aluminum composite panels are used for cladding and architecture.

• Furniture and Interior Design: Decorative aluminum panels and artistic installations.

• Electronics: Heat sinks, enclosures, and precision housings.

We offer tailored CNC router solutions aimed at these industries, for maximum compatibility and output.

CNC routers and machining centres can cut aluminum, but their paths diverge in performance and application:

|

Feature |

CNC Router |

|

|

Cutting Speed |

High |

Moderate |

|

Rigidity |

Medium |

High |

|

Material Thickness |

Thin to medium sheets |

Thick blocks |

|

Surface Finish |

Excellent |

Excellent |

|

Cost |

Lower |

Higher |

|

Application |

Sheet cutting, signage, light parts |

Heavy components, molds |

CNC routing machines are providing more productive and cheaper manufacturing solutions for the light industry. Furthermore, the aluminum parts of high precision are from duly recognized producers.

You will need to focus on the production process which the CNC router is being selected. The thickness of the material at hand for the cutting will be. In turn, define the precision of the work at hand. In turn, define which characteristics should be sought for in a machine. Some of these features include:

● Machine Rigidity: The Designer is to reduce vibration through a cast iron or steel frame.

● Spindle Power: For aluminum, 4.5–9 kW is recommended.

● Worktable Size: Choosing one router table to suit your most common sheet size is ideal.

● Tool Change System: If working with lots of different bits, consider an ATC (Automatic Tool Changer).

● Controller Compatibility: Use a system that will be compatible with common CAD/CAM software.

● After-Sales Support: Buy from a manufacturer that includes installation and support.

A CNC router for aluminum is more than just a cutting tool, serving as a backbone for modern, efficient manufacturing. With great detail and consistency, along with minimal waste, aluminum CNC routing serves industries like automotive, aerospace, signage, and interior design.

Backed by two decades of experience and world-class engineering, we offer CNC machines that change the way precision and reliability are defined. Our routers are built to tackle your every aluminum project with strength, speed, and great accuracy.

A CNC router machine for aluminum is used in the manufacture of aluminum sheets, plates. Other components through cut, engraved, and shaped in a very accurate manner by computers. It is primarily used for cutting components with complex designs in bulk industries such as aerospace, automotive, construction, and signage.

Using the latest technology in high-speed spindles, rigid frames, and the right cutting tools. Modern CNC routers can effectively cut aluminum. Mist cooling and the appropriate feed rates contribute to the smooth finishes achieved while avoiding wear in the tool.

Among others, 6061, 5052, 7075, and 2024 aluminum grades are really good for CNC routing. Each of the alloys comes with different benefits, like 6061, for instance. It is an excellent alloy for general machining. 7075 has superior strength levels for aerospace and defense components.

CNC routers are faster and cheaper. It is suited for thinner aluminum sheets. It is best for larger production volumes, with milling machines handling the thicker and heavier parts. General applications on those involve cutting, engraving, or sign-making, which is better done by CNC routers.

For aluminum machining, it's best to use 1- or 2-flute solid carbide bits. They have better evacuation of chips, which is recommended for surface finish. Just as good for long-term uses in high-volume cuttings are diamond-coated bits.