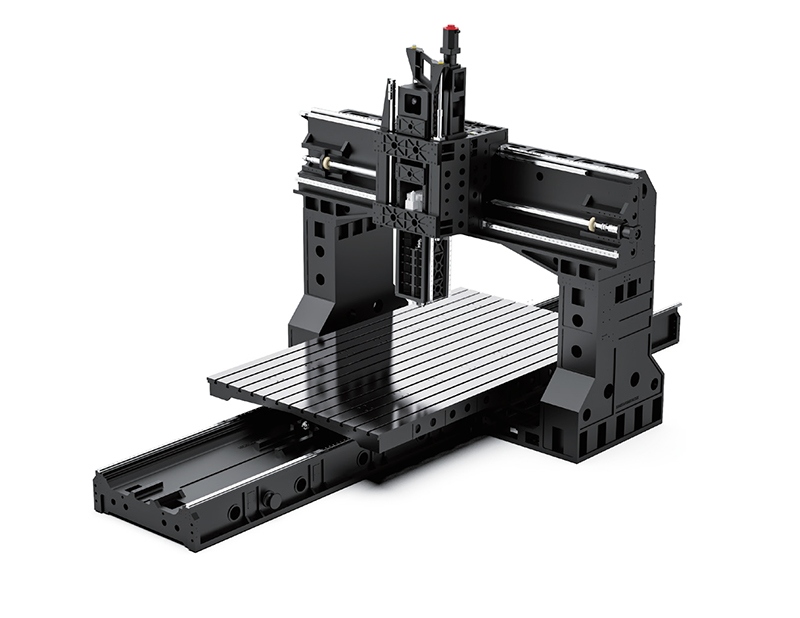

The gantry machining center is a high-precision, high-efficiency CNC machine tool, mainly used for processing large and complex workpieces. Its structural feature is a gantry frame composed of beams and columns, which provides high rigidity and stability and is suitable for heavy cutting and high-precision processing. It is widely used in aerospace, mold manufacturing, energy equipment, shipbuilding and other fields

The gantry machining center refers to the machining center in which the axis of the Z axis of the main shaft is perpendicular to the table. Especially suitable for machining large workpieces and workpieces with complex shapes.

X/Y/Z Axis: 1500*1700*1000

Spindle: BBT50

Fastest Tool Change Time: 4.9sec

The Maximum Load Capacity of The Workbench: 2t

Cutting Feed: 8000mm/min

| Traditional structure | Yangsen new |

Traditional structure: double track T-type ram. The traditional structure is connected by a belt, which has high noise and poor dynamic balance effect. It is easy to produce vibration tool marks during processing and cannot be processed at high speed. |

Yangsen new: four-Rail square ram. The built-in direct connection design reduces the power transmission consumption from the spindle motor to the spindle. |

Traditional structure double track T-type ram The traditional T-shaped ram adopts the design of double track (6 sliders), which has poor rigidity. |

Yangsen new four-Rail square ram Yangsen adopts four-line rail (10 sliders) square ram structure design, which has stronger rigidity |

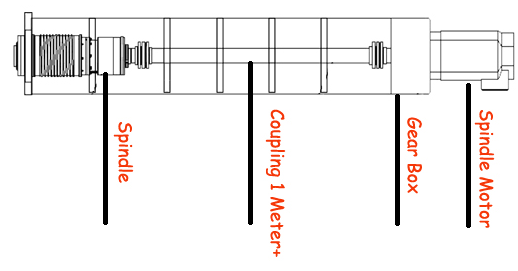

Common square ram: direct coupling spindle Common square rams are driven by long couplings, and the length of the coupling is too long to easily cause motion: 1. Poor dynamic balance effect 2. Low transmission rate 3. There is a problem of torque loss |

Yangsen new: built-in motor spindle Yangsen’s new model adopts built-in direct installation, cancels the long coupling and reduces the use of built-in direct installation: 1. Reduce the problem of torque loss in long couplings 2. Improve machining accuracy and cutting rigidity 3. Good dynamic balance for finishing and high surface finish |

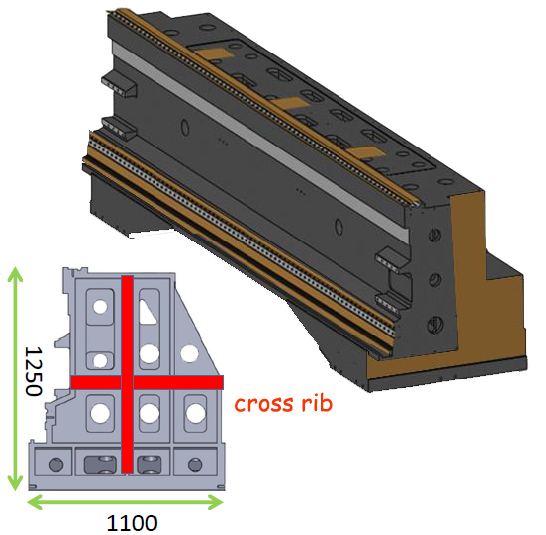

Traditional:Structural Beams. The traditional structure only has no reinforcement ribs inside the beam box structure. |

Yangsen new:Cross rib thickened beam. Yangsen’s new beam has a large span and adopts a cross rib structure with strong deformation resistance |

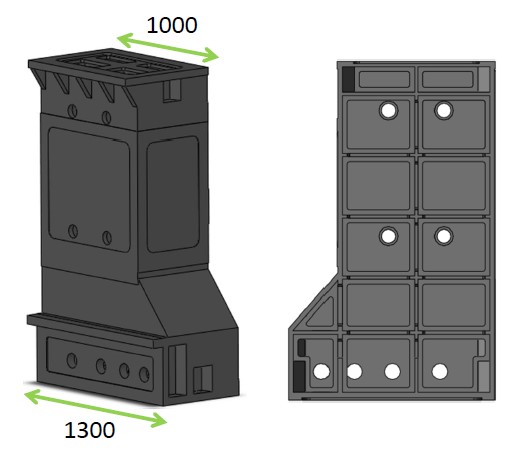

Traditional:Structural Columns. |

Yangsen new:Sun rib Columns 1. The one-piece cast column structure, combined with the thick column section size, effectively connects the rigidity transmission between the beam and the base, and greatly improves the cutting rigidity of the YZ axis. 2. The sun-shaped rib design inside the column provides high stability and high rigidity |

|

1. Split bearing motor base, the coaxiality of the bearing and motor installation holes is difficult to control; the screw and the motor are connected by a belt, there is a gap, and the transmission rigidity is poor. 2. The auxiliary support structure of the fixed-point lead screw, the spring support force is unstable, and the gravity deformation of the follow-up support lead screw is large. |

1. Yangsen’s One-piece bearing motor base, strong rigidity, high coaxiality of the bearing and motor installation holes; the connection between the screw and the motor is connected by a planetary reducer, no gap, and good transmission rigidity 2. The follow-up screw auxiliary support structure reduces the influence of the position accuracy caused by the gravity droop of the long-stroke screw |

Aerospace: Processing titanium alloy aviation structural parts.

Energy industry: Processing of large wind turbine gearbox housings.

Mold manufacturing: Automotive die-casting mold integrated molding.

The table of the gantry machining center is basically rectangular. The large and heavy castings such as the table, bed, column, beam, and ram are made of cast iron or welded parts. The inner cavity of the casting is a honeycomb composite arrangement structure with advanced design, all of which have been treated by aging and secondary tempering to eliminate residual internal stress and stabilize the material, to ensure the stability of workpiece machining accuracy and machine tool life.

Using BBT50-D200 high rigidity spindle, 6 imported large steel ball bearings, super cutting ability.

The gantry consists of a beam and two columns. It can be divided into three types: beam fixed, beam locked by positioning block segmented lifting, and beam free lifting.

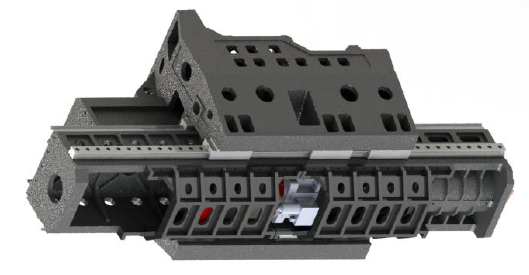

The ram can be divided into two types: open type and closed type. The ram of the open structure is clamped on the headstock by the pressure plate, and the cross-sectional area of the ram is large; the ram of the closed structure is clamped in the headstock, and the cross-sectional area of the ram is small.

There are three basic types of tool magazines: turret type, drum type, and chain length type.

The machining of large, heavy, and complex parts often requires many attachment heads. The attachment head is specially designed according to the processing requirements of the workpiece and is generally divided into a right-angle head, extension head, special angle head, and universal head.

There are many CNC system suppliers, and there are different choices of system brands and models according to different needs.

The accuracy of the machine tool refers to the original accuracy of the machine tool under the condition of no external load. Accuracy is usually represented by its opposite - the deviation from the ideal state (abbreviated as error), and the smaller the error, the higher the accuracy.

Yangsen offer 2 series for Gantry Machining Centers:

The YSM is a double-column machining center that has strong rigidity, a symmetrical structure, and high stability. Through continuous optimization of the component structure, the dynamic performance of the product is improved, and high-power, high-torque, high-efficiency, and high-precision machining are realized. It is suitable for large-scale processing fields such as shipbuilding, metallurgy, mining machinery, power energy, construction machinery, heavy industry machinery, and more.

|

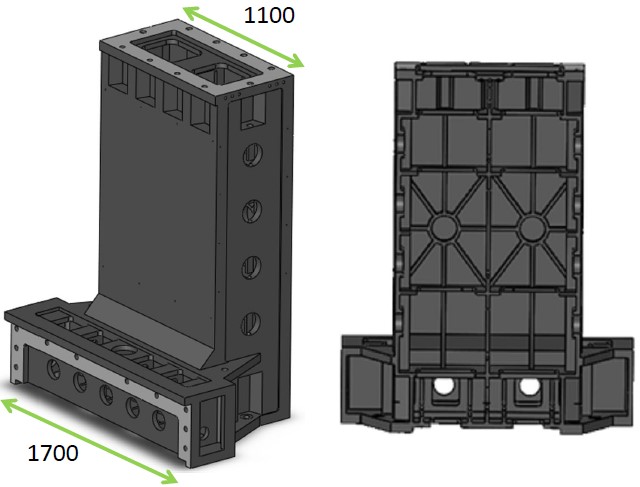

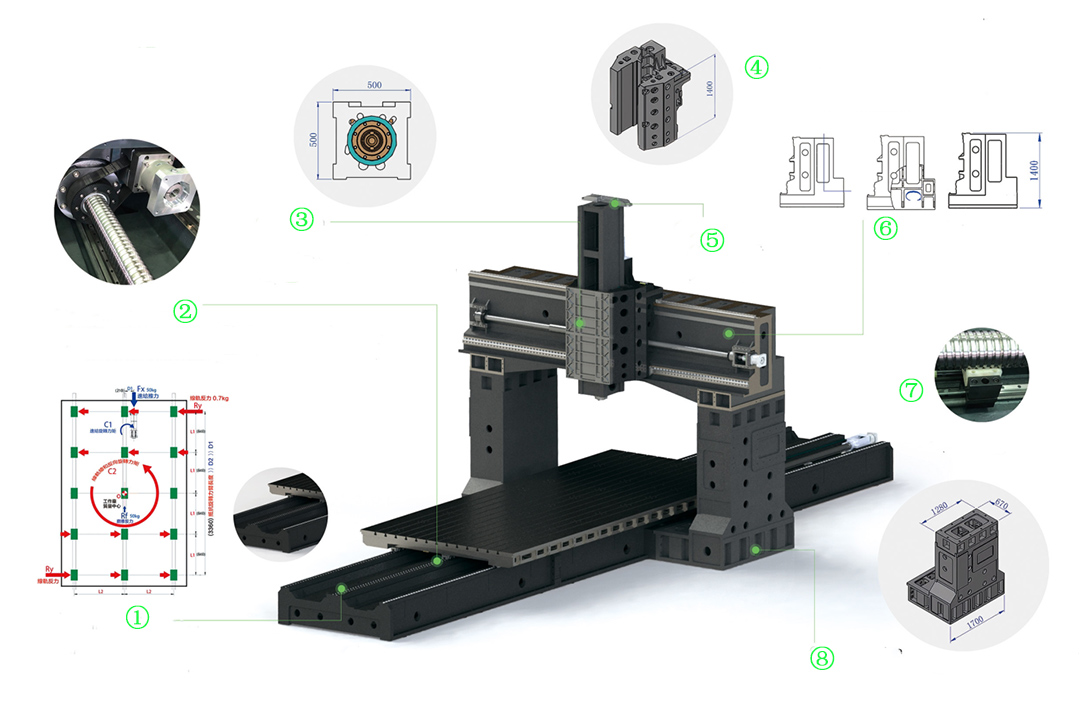

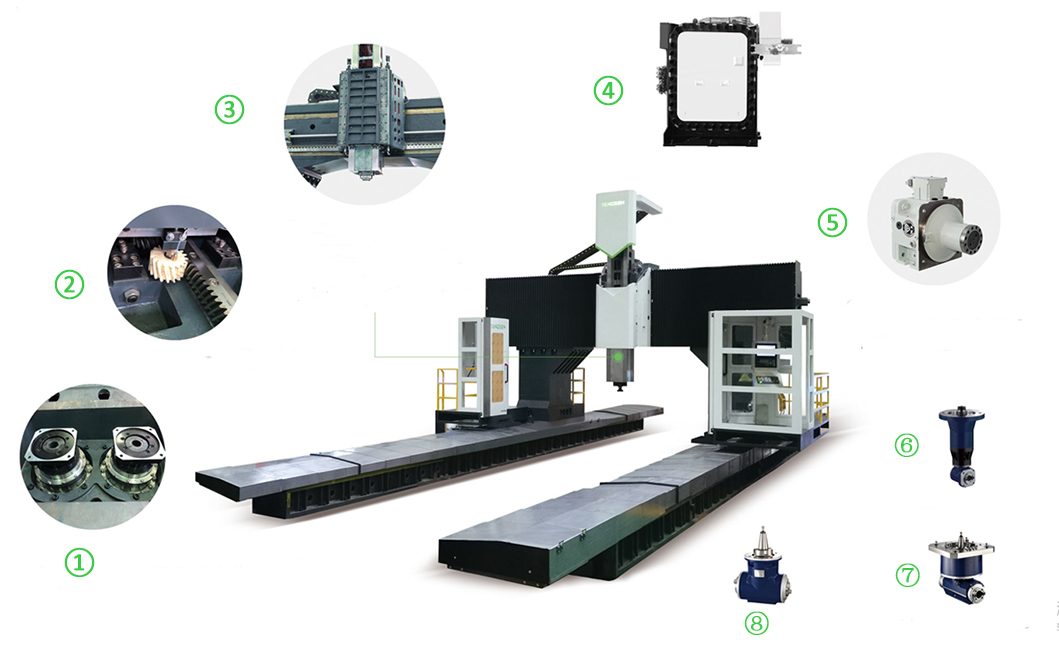

①. Base structure: Compared with the double-guideway design, the rigidity is 50% higher; Compared with the four-guide ways design, it is more symmetrical and evenly distributed, reducing the power loss caused by the resistance of the multi-guideway slider;3m wide worktable, 2.1m base linear guideway. It is the best ratio span of 0.7. ②. Gantry moving nut structure: The X-axis is driven by a moving nut, and three-point support is used in the middle to maintain the rotation accuracy of the ball screw rod. At the same time, the load capacity is large, and the cutting vibration resistance is good. It can improve the dynamic characteristics of the machine tool and increase the accuracy, stability, and service life of the machine tool. ③. Square Ram: Bigger dimensions. It is a more heavy-duty design; The built-in direct connection design reduces the power transmission consumption from the spindle motor to the spindle. ④ Slide features The large-size and heavy-duty design ensure that the upper part of the ram is firmly hugged by the three elongated sliders, and the lower part is supported by the four standard sliders. ⑤. Nitrogen counterweight: Reduce the load of the motor and the bearing force of the ballscrew, increase the life of the ballscrew and the motor, and the acceleration of the Z axis to ensure processing accuracy. ⑥. Beam structure: The stepped L-shaped design improves rigidity; The concave C-shaped structure has better-bending resistance; Large section design; Finite element analysis. ⑦. Ballscrew support frame system: ⑧. Column structure: The 1.28m ultra-wide design of the column reduces the overall cutting vibration and makes the machine tool stable. |

|

YSM23/27 Series: 2-line tracks and 1-hard rail.

| Model | YSM-2013 | YSM-2015 | YSM-2217 | YSM-2518 | YSM-3018 | YSM-3023 | YSM-4023 | YSM-4027 | YSM-6027 | YSM-4027Ram |

| Travel X/Y/Z mm | 2000/1300/800 | 2000/1500/800 | 2200/1650/800 | 2500/2000/960 | 3000/2000/960 | 3000/2300/1000 | 4000/2300/1000 | 4000/2700/1000 | 6000/2700/1000 |

4000/2700/1000 Optional 1250 Z axis |

YSMV Series: 3-line tracks.

| Model | YSMV-2013 | YSMV-2817 | YSMV-3021 | YSMV-5021 | YSMV-3027 | YSMV-5030 | YSMV-7030 |

| Travel X/Y/Z mm | 2000/1300/800 | 2800/1900/800 | 3000/2600/1000 | 5000/2600/1000 | 3200/3000/1300 | 5000/3200/1300 | 7000/3200/1300 |

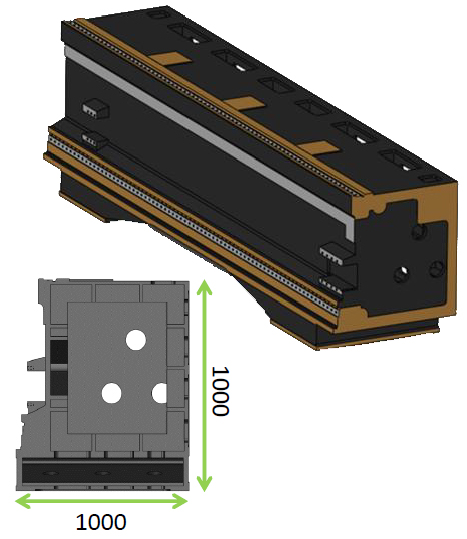

YSM28/32 Ram Series: 2-line tracks and 1-hard rail.

| Model | YSM-3028 | YSM-5028 | YSM-7028 | YSM-5032 | YSM-7032 | YSM-9032 |

| Travel X/Y mm | 3000/2800 | 5000/2800 | 7000/2800 | 5000/3200 | 7000/3200 | 9000/3200 |

| Z mm |

1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) |

YSM34/42 Ram Series: 2-line tracks and 1-hard rail.

| Model | YSM-5038 | YSM-7038 | YSM-9038 | YSM-5042 | YSM-7042 | YSM-9042 |

| Travel X/Y mm | 3000/3800 | 5000/3800 | 7000/3800 | 5000/4200 | 7000/4200 | 9000/4200 |

| Z mm | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) |

Double column construction, providing high rigidity support. Adopt a counterweight balance, making the machine move stably, and reducing the load of the ball screw, keeping the accuracy for a long time.

Moving column machining center fixed beam double gantry moving machining center can process a workpiece at the same time, also can process two workpieces at the same time, high processing efficiency, small footprint. It can finish the above processing efficiently and with high precision in a clamping process.

|

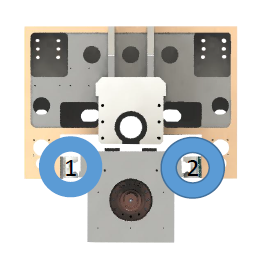

①. Dual Motor with Anti-Backlash Transmission Structure: High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life. ②. Gear Transmission: High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life. ③. Square Ram and Sliding Seat Structure: Direct-Driven Design; Large-Size and Heavy-Duty design ensures that the ram is firmly connected; Three extended sliders at the top and four standard sliders at the bottom. ④. Vertical / Horizontal Automatic Tool Magazine: ⑤. Italy BF Gear Box: High-performance speed, low noise. It could expand the motor's constant power range. It is easy to install. The machine can be used in conjunction with multiple series of motors. It can adapt to high-strength tension and small size. ⑥. Extended Angle Milling Head ⑦. Automatic Hydraulic Angle Milling Head ⑧. Two-Way Spindle Angle Milling Head |

|

YSMD Series:

| Model | YSMD-6042 | YSMD-8042 | YSMD-10042 | YSMD-12042 | YSMD-14042 | YSMD-16042 | YSMD-18042 | YSMD-21042 |

| Travel X/Y/Z mm | 6000/4200/1500 | 8000/4200/1500 | 10000/4200/1500 | 12000/4200/1500 | 14000/4200/1500 | 16000/4200/1500 | 18000/4200/1500 | 21000/4200/1500 |

| Model | YSMD-6046 | YSMD-8046 | YSMD-10046 | YSMD-12046 | YSMD-14046 | YSMD-16046 | YSMD-18046 | YSMD-21046 |

| Travel X/Y/Z mm | 6000/4600/1500 | 8000/4600/1500 | 10000/4600/1500 | 12000/4600/1500 | 14000/4600/1500 | 16000/4600/1500 | 18000/4600/1500 | 21000/4600/1500 |

M Series Gantry Machining Center is engineered for high-rigidity, high-torque, and long-term stable machining of large and heavy workpieces.

With a monoblock symmetric gantry structure and optimized dynamic design, it delivers excellent performance in heavy cutting, precision milling, and large-part machining.

This series is widely applied in shipbuilding, metallurgy, mining, power generation, engineering machinery, and heavy industry manufacturing.

|

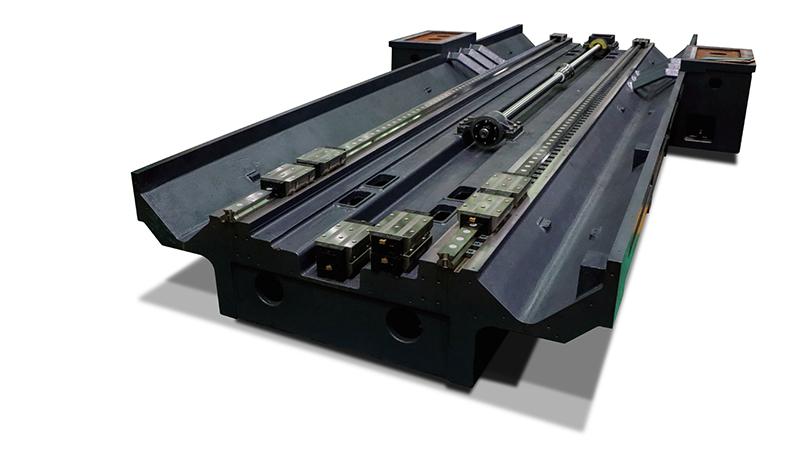

Monoblock Base Casting: • Rib Reinforced Rigid Base Design. • Integrated chip channels; enhanced rigidity/stability. • Perpendicular ribbing under linear guides: Eliminates lateral force components. • Hermetic design prevents oil leakage. • Work height: 715mm (ideal workpiece access). Rational bed height: Ensures uncompromised stability.

|

|

Monoblock Symmetric Gantry Design: • Radial ribbing: Prevents beam deflection. • Heavy-section columns/beams: Enhanced rigidity. • Precision-ground beams: High flatness tolerance. • Y-axis clearance: Side-milling capability. |

|

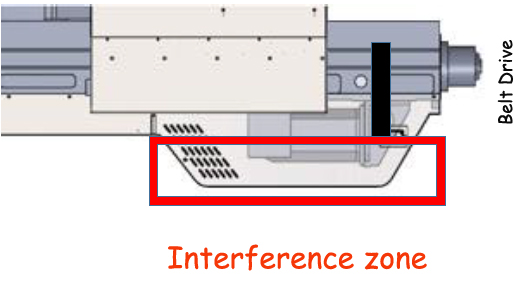

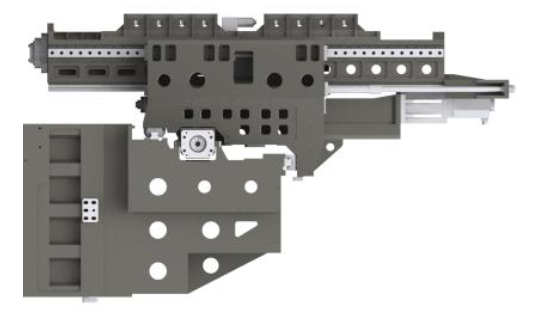

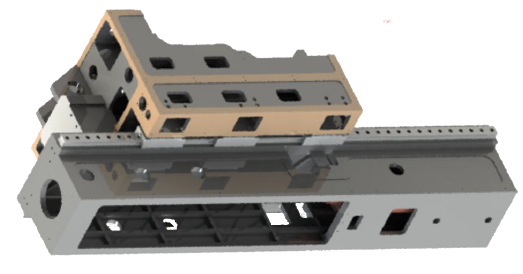

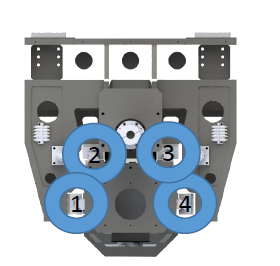

Symmetric Quad Linear Guides: • (4×45mm) on ram ensures superior rigidity for high-speed precision cutting. • Direct-drive BBT50-Φ190 spindle with compact cross-section minimizes interference zone, enhancing rigidity and thermal stability. |

|

Triangular Cross-Section Saddle Design: • Increased Y-axis rail span reduces machining vibration. • Optimized CG proximity to drive axis enhances dynamic stability. |

MHE And MVE Series:

| Model | MHE-1518 | MHE-2218 | MHE-3018 | MVE-1518 | MVE-2218 | MVE-3018 | MHE-1810 | MVE-1810 |

| X mm | 1500 | 2200 | 3000 | 1500 | 2200 | 3000 | 1800 | 1800 |

| Y mm | 1800(Auxiliary Travel 150) | 1000 | 1000 | |||||

| Z mm | 1000 | 1000 | 1000 | 800 | 800 | 800 | 800 | 820 |

|

Spindle BBT50-Φ190mm low-nose spindle | 6 high-rigidity bearings | Heavy-cut capability. Automatic Angular Milling Head Precision hardened transmission. Minimal backlash. Long service life. Italian BF Gearbox High torque / low noise Compact design | Easy installation Extended constant-power range ATC Vertical/horizontal tool magazine | Rapid response Optional 24T / 32T / 40T 5-Axis Bidirectional Head A/C axes: Torque motors + electro-spindle Hydraulic clamping: High-speed stability. |

|

NHE and NVE Series:

| Models | NHE-3028 | NHE-4028 | NVE3028 | NVE-4028 |

| X mm | 3000 | 4000 | 3000 | 4000 |

| Y mm | 2800(Auxiliary Travel 300) | |||

| Z mm | 1050 | 1050 | 800 | 800 |

|

|

This X series gantry machining center features a high-rigidity, symmetrical structure that ensures stable and accurate machining of large and heavy workpieces.

With optimized dynamics and high-torque capability, it delivers efficient and precise performance for heavy-duty cutting operations.

It is widely used in shipbuilding, metallurgy, mining, power generation, and the manufacturing of heavy machinery.

Base

The base is equipped with integrated lifting bosses for safer and more efficient handling during transportation and installation.

A radial ribbing pattern, combined with an optimized I-beam structure, significantly enhances overall rigidity and structural stability.

Column

The column features a 1200 mm base width, representing a 20% increase compared to conventional designs.

This reinforced structure improves load-bearing capacity and ensures stable support for high-load and high-torque machining operations.

Ram

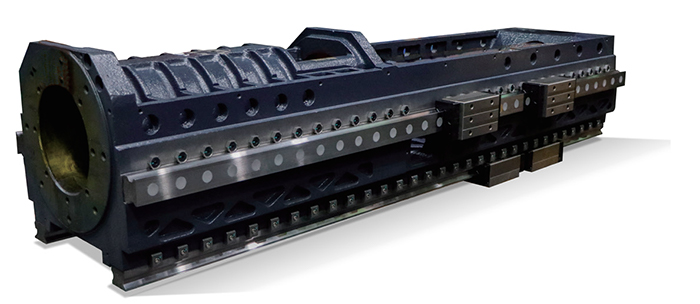

The ram adopts a composite reinforcement design with triangular and trapezoidal ribbing.

An expanded beam cross-section and internal radial ribs maximize rigidity, supporting stable cutting performance during heavy-duty machining.

Table

The worktable utilizes an arched structural design to increase payload capacity.

This design effectively reduces resonance during machining, contributing to improved vibration control and overall machining stability.

Guide System / Square Ram

The guide system uses four linear guides in a symmetric layout, ensuring balanced load distribution and smooth axis motion.

The machine is equipped with a 420 × 420 mm square ram, providing enhanced rigidity and stable motion control for heavy cutting applications.

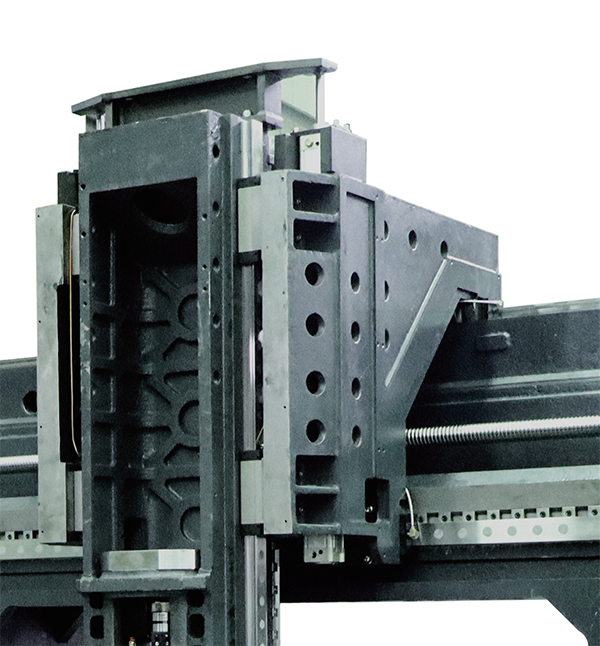

Spindle Head

The spindle head features a side-mounted ballscrew design, which shortens the spindle-to-beam distance and enhances structural stiffness.

A double-wall housing enhances rigidity, while the Z-axis square ram with quad linear guides ensures stable and precise spindle movement.

XVE Series:

| Models | XVE-5030 | XVE-7030 | XVE-5035 | XVE-7035 | XVE-9035 | XVE-10035 |

| X mm | 5000 | 7000 | 5000 | 7000 | 9000 | 10000 |

| Y mm | 3000(Auxiliary Travel 200) | 3500(Auxiliary Travel 300) | ||||

| Z mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

XVS Series:

| Models | XVS-5041 | XVS-7041 | XVS-9041 | XVS-10041 |

| X mm | 5000 | 7000 | 9000 | 10000 |

| Y mm | 4100(Auxiliary Travel 200) | |||

| Z mm | 1300 | 1300 | 1300 | 1300 |

XHE Series:

| Models | XHE-5030 | XHE-7030 | XHE-5035 | XHE-7035 | XHE-9035 | XHE-10035 |

| X mm | 5000 | 7000 | 5000 | 7000 | 9000 | 10000 |

| Y mm | 3000(Auxiliary Travel 200) | 3500(Auxiliary Travel 300) | ||||

| Z mm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

XHS Series:

| Models | XHS-5041 | XHS-7041 | XHS-9041 | XHS-10041 | XHS-7047 | XHS-9047 | XHS-10047 |

| X mm | 5000 | 7000 | 9000 | 10000 | 7000 | 9000 | 10000 |

| Y mm | 4100(Auxiliary Travel 200) | 4700(Auxiliary Travel 200) | |||||

| Z mm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |