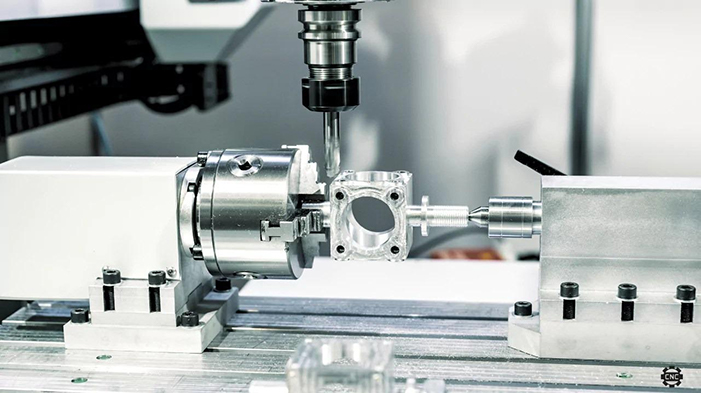

The manufacturing sector is and has always been a highly competitive environment in which the balance between speed, precision, and cost directly determines success. Although CNC machines have improved the ability to create complex parts, there is always pressure to increase throughput. This is a challenge that job shops and large-scale manufacturers have to deal with daily.

Every manufacturer knows the struggle—machine hours are expensive, delivery deadlines are tight, and competition is tough and fierce. The difference between profit and loss often comes down to seconds per part. CNC machining cycle time optimization has become the holy grail of manufacturing efficiency.

In this CNC machining guide, we will examine the tested methods that can make you cut your CNC machining cycle time to revolutionize your manufacturing process. These strategies will enable your company to achieve a higher level of productivity, cut costs, increase your bottom line, and produce improved customer results.

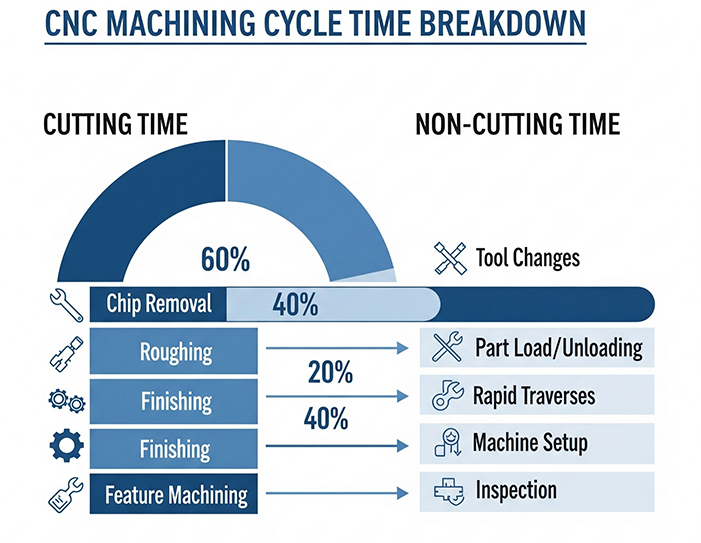

Before proceeding to optimization strategies, it’s important that we discuss what CNC machining time is. Most operators have this misconception that cycle time is the actual cutting time that the tool is in contact with the material. In the real world, cycle time is the entire span of time between the start of a part undergoing processing and the end of that part having gone through the entire process.

Deconstructing cycle time yields two broad categories that influence efficiency. Noncutting time incorporates the setup and fixturing, tool change, rapid traverse, air cutting motions, and loading and unloading of parts. These activities are known to consume 40-60 percent of total cycle time, and yet they add no value to the finished part. This is a huge potential area of improvement that is ignored by most shops.

Cutting time refers to the mechanical processes of removing material, and includes roughing cuts to remove bulk; semi-finishing cuts to establish near-final dimensions; and finishing cuts to achieve final surface quality and tolerances. It should be noted that the rate at which the material is removed during these operations directly affects the productivity, and therefore, optimizing the cutting time is a very complex procedure involving profound knowledge of the tooling, materials, and machining parameters.

Knowledge of the importance of every second will help to justify investments into cycle time reduction. A decrease in cycle time of 10 percent can make a significant difference in the cost-per-part calculations, particularly in high-volume production. Increased cycle times also translate into improved machine utilization rates, and manufacturers will be able to do more work with the existing machines. Lead time is always a critical factor in competitive biddin,g and shorter lead time is normally the difference between winning and losing contracts.

The foundation of efficient CNC machining begins long before the first chip hits the floor. Pre-machining strategies set the stage for everything that follows, making them perhaps the most critical factor in achieving optimal cycle times.

The choice of smart design directly impacts the efficiency of machining in ways that are not well understood by many engineers. All of the features on a part drawing carry implications for cycle time, tooling, and set-up complexity. Knowledge of these relationships during the preliminary design stage will avoid wasting money on inefficiencies in the production stage.

Protruding features such as small radii, deep pockets, and internal features are common features that may require special tooling with slower feeds and speeds. These properties also generally require numerous tool changes and sensitive programming to prevent tool breakage. By altering configurations to employ larger radii, less-steep pockets, and easier geometries, it is often possible to employ standard tooling and generate much higher material removal rates.

Having a consistent hole size and thread type across product lines diminishes the number of tools necessary to produce the products. This simplification not only reduces the number of tool changes made in machining, lowers the amount of inventory required, but also enables the operator to become very knowledgeable of a limited number of tools. Saving such small amounts can result in a radically shorter CNC cycle time in an entire product family.

The accessibility of features is also very important in relation to machining efficiency. Good tool access in parts means that more aggressive cutting parameters can be used, and special tooling is not needed as frequently. Where features are required to be accessed in more than one direction, note the implications on setups and whether this can be redesigned to reduce setups.

Choice of materials can have a profound effect on the machining parameters and cycle times. Certain materials will machine faster than others, and selecting the correct grade can mean the difference between a profitable job and a loss. Such as magnesium alloys are exceptionally easy to machine, with cutting speeds 3-5 times faster than aluminum, and acceptable surface finishes.

New technology in the tooling industry has transformed the material removal rates and tool life. Top-quality solid carbide end mills with newer coatings such as TiAlN and AlCrN are able to withstand much higher speeds and feeds than older tools. These tools pay off their higher price with improved productivity and extended tool life, resulting in a lower cost-per-part.

Tool geometry is application-specific and hugely differentiated in performance. A general-purpose end mill can be used on most applications; however, a tool that has been tailored to your material and operation will always perform better. Helix angles can be varied to minimize chatter, chip gullets are optimized to maximize chip evacuation, and special coatings are used to resist wear in certain materials.

It is important to understand how the choice of tools relates to machining parameters to optimize them. The right tool will enable you to machine aggressive parameters safely, whereas the unfavorable tool requires you to machine conservatively to avoid breakage. This variation can easily increase cycle times in demanding applications twofold or even threefold.

The current generation of CAM software is much more than generating G-code based on part geometry. High-end CAM systems have sophisticated optimization facilities that can save huge amounts of cycle time with clever toolpath creation. These systems examine part geometry and automatically determine highly efficient machining sequences that will minimize the number of tool changes and air cutting time.

Toolpath optimization capabilities, such as automatic rest machining, make sure that each tool can only remove the material that can be removed efficiently. This ensures smaller tools are not used to attempt to remove a lot of material, and larger tools are used to accomplish the majority of work within the shortest time possible. The consequence is much shorter cycle times and better tool life.

With the simulation capabilities, programmers are able to detect and remove inefficiencies prior to reaching the shop floor. With virtual machining, issues such as too high rapid movements, unneeded tool exchanges, and possible collisions are exposed that would otherwise result in delays in production. This initial cost of simulation investment will be rewarded with a decrease in the setup time and the number of surprises.

Advanced simulation also allows optimisation of cutting parameters for particular applications. CAM software can offer optimal speeds and feeds by simulating the real-world cutting forces and temperatures associated with them. This scientific methodology always outperforms its trial-and-error counterparts when it comes to selecting the parameters.

Once parts reach the machine tool, in-process optimization techniques determine how efficiently material gets removed and parts get completed. These strategies focus on maximizing the productivity of actual cutting operations while maintaining quality standards.

High-speed machining is a conceptual change over the heavy cutting methodologies. Rather than making thick cuts at low speeds, HSM makes shallow cuts at high RPMs to attain high material removal rates. This method is especially effective in tougher materials and in thin-walled components where the heavy cutting would tend to vibrate or distort.

The advantages of HSM are not limited to the increased cutting speeds. Light forces of cutting wear down the tool less, enhancing surface finish and tool life. The lowered cutting forces can also enable the machining of thinner walls and more delicate features, which would otherwise never be possible using conventional methods. In most of the applications, HSM can do away with secondary finishing operations.

High-Efficiency Machining is a new approach, as it maximizes material removal by intelligent toolpath planning and not only by high speeds. Adaptive clearing and trochoidal milling methods keep tool engagement and chip loads constant, which enables tools to run at their full capacity throughout the process.

Trochoidal milling is worth a mention since it can slash cycle times in coarse machining. Rather than the traditional slotting or plunging, circular interpolation-based trochoidal toolpaths provide the optimal chip loads and efficient cutting of material. The technique has the potential to improve material removal rates up to 300-500% as compared to standard roughing strategies.

The high chip load that is maintained in HEM operations also increases tool life. Conventional machining usually exposes tools to different loads and leads to faster wear, but HEM ensures that tools are working in their sweet spot at all times. This dependability enables more aggressive programming and unattended operation.

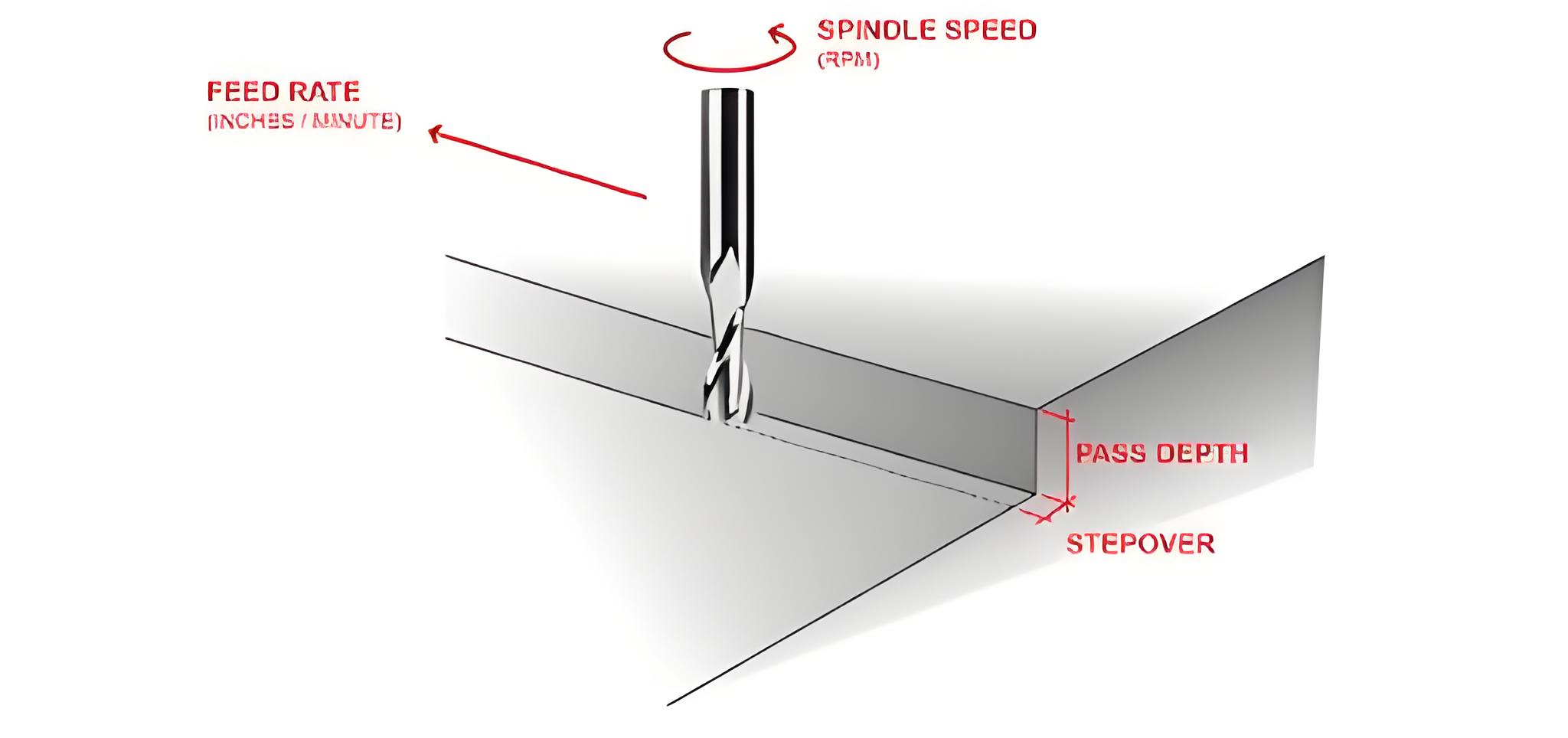

Finding the ideal cutting parameters is more than just putting numbers into the standard formulas of spindle speed and feed rate. Although such calculations are a good place to start, actual optimization must take into account the rigidity of the machine, tool life requirements, the properties of the material, and the demands of a particular application.

Machine rigidity is an extremely important factor in parameter selection since stiffer set-ups are capable of much more aggressive cutting conditions. When the same part is in a sturdy fixture on a heavy machine, the parameters could lead to chatter and poor surface finish in a less rigid setup. Knowledge of equipment gives you an understanding of what your equipment can handle.

Tool life considerations tend to cause trade-offs between cycle time and tool costs. Running tools at full load minimizes the cycle time but will shorten tool life. The best balance would depend on your unique circumstances. Volume production may justify shorter tool life because of faster cycle time, whereas job shop work may favor longer tool life so as not to interrupt the work.

Data on software calculators and tool manufacturer data are very good starting points to select parameters, but the best performance is achieved by fine-tuning this to actual results. Surface finish, dimensional accuracy, and tool wear monitoring tools are useful in determining the best parameters to use in each case. This iterative strategy always gives a superior result compared to just the use of handbook values.

New tool monitoring systems can automatically change parameters in relation to real-time cutting conditions. These systems monitor changes in cutting forces, vibration, and temperature to adjust parameters on a continuous basis to optimize them. This dynamic optimization is able to increase both the cycle times and the tool life.

The ability of the multi-axis machining to reduce setups and produce complex shapes in a single operation can greatly reduce cycle time. A 5-axis machine may be able to execute a part in one setup that could take several setups on a 3-axis machine, all of which save transfer time and setup error, and can improve accuracy.

The most important factor in maximizing the benefits of multi-axis is to program to utilize the capabilities of the machinery. Basic 3-axis programs on 5-axis machines do not utilize the capabilities of the machine. Proper 5-axis machining can reach features at the best angles, shorter tools to reduce deflection, and have a clear path to chip removal during complex machining.

The innovations in fixturing can significantly shorten the set-up time and part access by cutting tools. Fixtures: There are modular fixturing systems that allow easy changeover between different part families, and tombstone fixtures to machine multiple parts at the same time. Quick-change fixture plates can cut setup times on repeat jobs down to a few minutes.

Fixture design must be able to offer clamping security as well as access to the tools. The most significant fixture retains parts in a secure manner whilst ensuring maximum access to cutting tools. This may include special designs of fixtures to deal with large production volumes or innovative use of modular components to deal with low volumes. The better fixturing usually pays off within a short time in the form of shorter cycles and fewer quality concerns.

Automation represents the ultimate evolution in cycle time reduction, enabling lights-out manufacturing and eliminating many manual interventions that slow production. While not every operation justifies full automation, selective automation of key processes can deliver dramatic improvements.

Robotic loading and unloading of parts also removes the time spent on repetitive tasks by the operators, whilst allowing continuous operation during breaks and shift changes. Contemporary robots are able to work with components of several hundred pounds in weight with a precision that is sometimes better than manual loading. Part quality is also improved by the uniformity of robotic loading since this ensures that the same clamping forces are used and identical positioning.

Automated part handling is even more valuable in high-volume production, where the loading/unloading of parts takes up a large percentage of the entire production cycle. A robot often can load the next part as the machine is still finishing the previous one, effectively removing loading time from the cycle. Such parallel processing can save overall cycle times by 20-30 percent in most applications.

Robotic, deburring, and automated inspection systems ensure quality standards without the necessity of any manual input. These systems have the capability of processing the parts just out of the machining point, and the machine can work on the next part, and it takes advantage of the overall throughput. Automated inspection also gives quality data in a consistent manner that can be used to optimize the whole process.

The problems of integration should not be underestimated; however, the new generation of automation systems is much more user friendly than the previous one. Most systems have simulation software that permits offline programming and debugging, reducing the interference with production when implementing the system.

Non-value-added activities that take time and do not improve the part could be eliminated by the lean manufacturing principles that are applied to machining operations. Minor adjustments, such as the efficient organization of tools, minimization of setup materials and handling processes, and the elimination of movements that are not necessary, can have a great effect on cycle times.

Tool organization may appear to be a minor issue, but operators who waste time looking to find tools or walking to tool cribs add considerable non-productive time to every cycle. Faceplates of organizational tools at the place of use and the creation of shadow boards or other visual management will keep everything within reach and minimize wasted motion.

Collection of data and ongoing improvement activities will allow for recognizing bottlenecks and opportunity areas that may not be evident in daily operations. Monitoring cycle times, tool life, and quality metrics will provide trends that will allow the improvement process to be directed. This methodological practice of optimization provides long-term gains.

Kaizen events of individual processes can achieve impressive gains within a short period. Conventions that unite operators, programmers, and engineers to examine and enhance certain operations usually come up with opportunities that would not have been detected by individuals acting individually. Improvements that are practical and sustainable are also achieved by the collaborative approach.

This guide covers a holistic approach to reducing CNC machining cycle time that goes beyond just running machines faster. True optimization starts with intelligent design and material selection, continues with advanced programming and cutting strategies, and ends with automation and continuous improvement processes.

Success in cycle time reduction requires systematic improvement, not random changes. The best manufacturers approach optimization methodically, measure results, and build on successes. This disciplined approach works better than trying to do everything at once.

Reduced cycle times have an impact beyond immediate cost savings. Faster production means better customer service through shorter lead times, faster cash flow through inventory turnover, and more capacity for growth without additional equipment investment. These benefits compound over time to create sustainable competitive advantages.

For manufacturers looking to optimize their high-precision machining, Yangsen CNC Machine Tools offers CNC solutions designed for maximum productivity and precision. Our machines have the latest technology to minimize cycle times while maintaining high accuracy and reliability. Contact us today to see how our CNC systems can transform your production and give you the competitive edge your business needs to succeed in today’s manufacturing world.