The main structure of a vertical lathe includes a vertical spindle and a rotating worktable. The worktable is usually quite large and can hold heavy workpieces. The spindle is positioned vertically, which is different from the horizontal spindle of a conventional horizontal lathe. The machine has a sturdy frame to support the heavy worktable and the cutting tools. The frame is designed to provide stability and rigidity to ensure accurate machining operations.

Max. X-axis Travel :

-200~+1050mmmMax. Z-axis Travel :

900mmMax Workpieces Height :

1400mmMax Workpieces Weight :

8000kgApplication :

Power generation, shipbuilding, metallurgy, and mining.Main Structure of CNC Vertical Lathe Machine

|

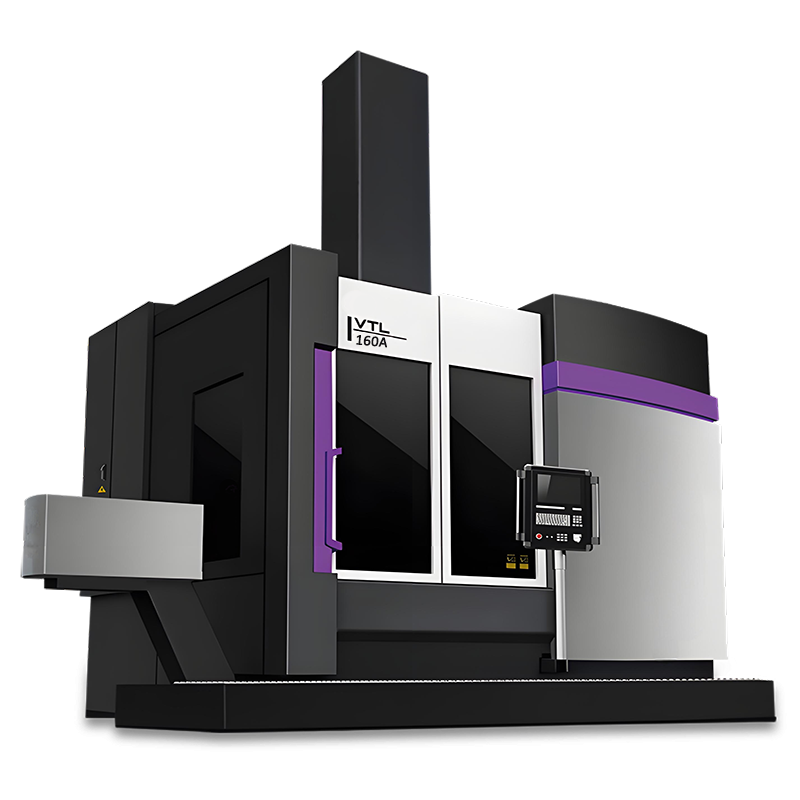

VTL-160A lathe is a single column CNC vertical lathe with movable beam, it is developed and designed by our company according to market demand, we make use of key technology process, proceed new design of lathe machine structure, do technical process research, and the work of lathe commissioning. VTL160A lathe is a single column CNC vertical lathe with movable beam, it is developed and designed by our company according to market demand, we make use of key technology process, proceed new design of lathe machine structure, do technical process research, and the work of lathe commissioning. |

Comprehensive After-Sales Support for Your Vertical Lathe

At CNC Yangsen, we are committed to providing full after-sales support to ensure your VTL-160A Vertical Lathe operates at peak performance. Our services include:

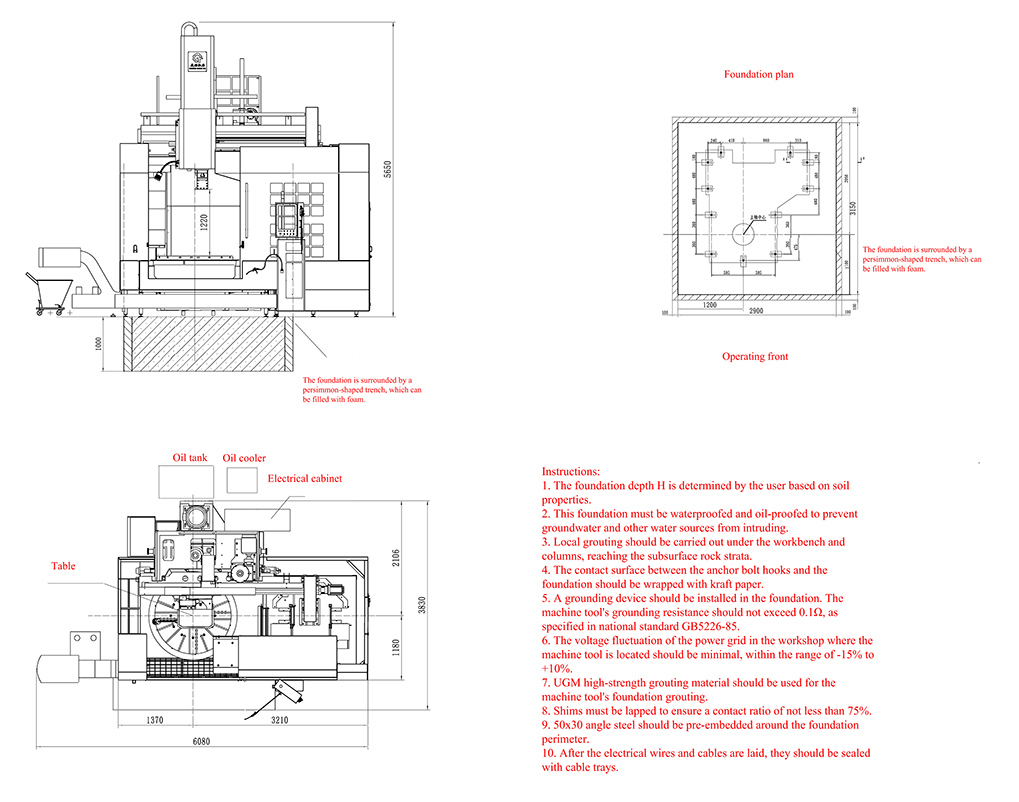

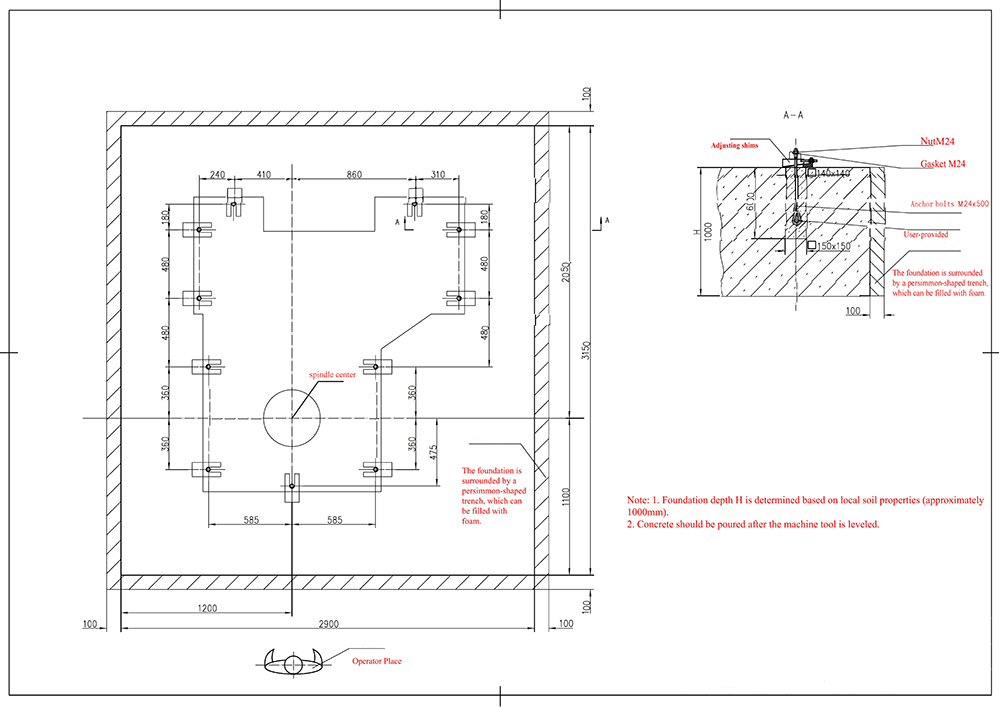

Foundation Layouts: We provide detailed foundation drawings to help you plan and install your machine accurately, ensuring stability and optimal performance.

Export & Installation Dimensions: Our technical team offers precise equipment dimension drawings for international shipping and on-site installation planning.

Technical Consultation: Our experts are available to guide you through installation, setup, and maintenance, ensuring minimal downtime.

With CNC Yangsen, you’re not just buying a machine—you’re gaining a reliable partner for long-term success.

Application of the CNC Vertical Lathe Machine

This CNC lathe machine is suitable for processing large parts in industries such as power generation, shipbuilding, metallurgy, and mining.

Key Technology Parameters of

| Item | Unit | Specification | |

| Main parameters | Worktable diameter | mm | 1400 |

| Max. Diameter of rotation | mm | 1700 | |

| Max. Diameter of the cutting | mm | 1600 | |

| Max. Height of work workpiece | mm | 1400 | |

| Max. Weight of work workpiece | Kg | 8000 | |

| Max. torque of worktable | N.m | 16500 | |

| Main gearbox | Rotation speed of the spindle | r/min | 1-300 |

| Main motor | Speed shift of the worktable | Gear | two gears, endless |

| Rated power/30 minutes | kW | 37 | |

| Continuous rated power | kW | 30 | |

| Ram | Ram section size | mm×mm | □220X220 |

| X-axis travel | mm | -200~+1050 | |

| Z-axis travel | mm | 900 | |

| Feeding speed | Feeding speed of cutting | mm/min | 0.1-1000 |

| Rapid feeding speed | mm/min | 6000 | |

| Tool holder | Single tool holder | 1 | |

| Turning tool rod size | mm×mm | 32×32 | |

| Tool changer | Tool tension of T-type | Number | 12 |

| Weight | Gross weight | Kg | 27500 |

| System | CNC model | FANUC oi TF | |

| Lathe Dimension | Length*width*height | mm×mm×mm | 5700X4850X5300 |

| Total power | Voltage | V | AC380 |

| Voltage fluctuation range | -10~+10% | ||

| Frequency | Hz | 50±1 | |

| Total power | kW | 53 | |

| The total power supply includes | Main motor | kW | 30/37 |

| Hydraulic motor | kW | 3.5 | |

| Motor for the cooling pump | kW | 0.75 | |

| X-axis servo motor | N.m | 27 | |

| Z-axis servo motor | N.m | 27 | |

| Lifting Motor | kW | 5.5 | |

| NC unit | KVA | 0.05 | |

| Control Panel | KVA | 0.02 | |

| Fan motor, lighting, etc.. | kW | 0.16 | |

| Motor of chip Removal | kW | 0.2 | |

| Pressure of Hydraulic System | Mpa | 5 | |

Tags :