The multi-axis CNC machines have shaped the industry like never before. Thanks to their accuracy and capabilities, companies may more comfortably produce more complex parts with high accuracy and precision.

These mechanical advancements have given several advantages that make them better than traditional machining. Aside from the better accuracy in production, they are present in different types that may offer unique perks and advantages for those who need it.

Before we discuss the advantages more, let us explain what a multi-axis CNC machine actually is.

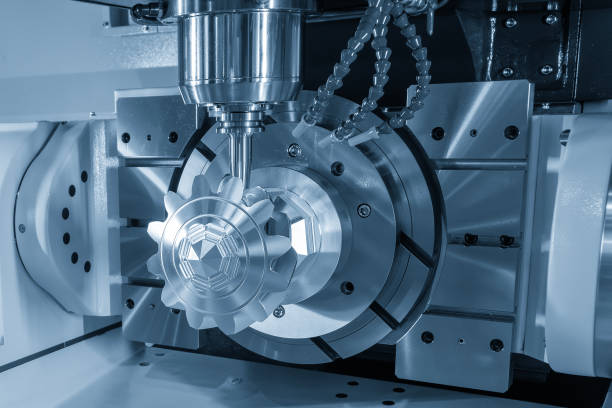

The multi-axis CNC machine is a type of CNC machine that uses several axes. With these axes, production of more complex parts is highly possible.

While more axes may provide better accuracy, these machines do have several challenges. The more complex the machine, the more complex the programming will be. To operate these machines, the skills of experienced operators are also needed.

The multi-axis machines may have 3-axis, 4-axis, 5-axis, and more than 5-axis. The more axes present, the better accuracy in production, which is useful for creating complex parts where accuracy is essential.

With their capabilities, companies may support a lot of industries, including health, aviation, aerospace, and more.

The multi-axis CNC machines stand out when compared to traditional machining. But in order to gain a better understanding, let’s discuss each of them in more detail.

In the manufacturing world, traditional CNC machines have been around for a long time. Its longstanding existence is made possible by its durability and capability to deliver quality work. The problem, however, is the limitations.

Traditional CNC machines are strictly limited to only using the three linear axes. These axes (X, Y, and Z), can move the cutting tool in order to shape the parts. Due to the structure, the traditional CNC machines may not be for producing complex and precise parts.

Therefore, there are the multi-axis CNC machines that become an upgrade. These machines can make use of the rotational axes to shape more complex parts with high accuracy. With multi-axis CNC machines, it’s possible to make curved shapes of the parts, undercuts, and other specific shape details.

So, when compared to traditional CNC machines, the multi-axis CNCs excel in performance, accuracy, and capability.

The multi-axis CNC machines work by moving the three rotational axes. Using three or more axes, the cutting tool can move more flexibly. The agile movements of the cutting tool make it possible to create the desired shape and form of the complex parts.

In order to create more precise parts, using more axes would be necessary. That’s why there are CNC machines with more than 5 axes for creating parts that require excellent precision and details.

The components of multi-axis CNC machines are the same, no matter how many axes there are:

This is one of the most important components of CNC machines. As you may know, the cutting tool is the part that’s responsible for shaping the desired shape. It cuts the workpiece and remove any unnecessary materials. Depending on the machine itself, the shape of cutting tool may vary.

The multi-axis CNC machines also have what we call spindles. There’s the main and pickoff spindle. The main spindle, or CNC spindle, is the component that grips and rotates the cutting tool. This part determines the machining speed and precision.

Aside from the main spindle, there’s the pickoff spindle. This sub-spindle is holding the part instead. While being worked on, the part should be in the most stable position. The sub-spindle helps by holding them together. It can also spin in the C-axis and the head moves along the Z-axis.

CNC machines need certain programming to make them run. To do so, the operator needs to input the program into the CNC Control Panel.

This is the part where an operator will configure the program and execute it. Aside from automatically running the program, the control machine may also offer a feature where the operator can guide the cutting tool manually.

When it comes to multi-axis machining, you will discover several types of them with their own capabilities and advantages. They do, however, have drawbacks that companies need to look into as well.

The more axis doesn’t always mean generally better as there are several challenges that may come with them. Below is the table highlighting the advantages and disadvantages of several multi-axis CNC machines:

|

|

3-Axis CNC Machines |

4-Axis CNC Machines |

5-Axis CNC Machines |

Beyond 5-Axis CNC Machines |

|

Descriptions |

The 3-Axis CNC machines are the basic form of multi-axis cnc machines and often picked becuase of how affordable they are compared to the other options.

With this machine, companies may achieve good results at cheaper prices.

Although it’s a part of multi-axis machines, it’s not technically true as the workpiece is stationary. With that in mind, the machine can work without having to adjust the workpiece. |

The difference between this one and 3-axis CNC machines is the additional axis.

Due to this insignificant addition, we couldn’t expect the specifications to increase dramatically. The workpiece is still stationary, after all.

However, we could at least expect better results from the fourth axis for producing more complex works.

|

When it comes to multi-axis machining, this is another popular option.

With better capabilities, the 5-axis CNC machines are often picked as dependable machinery to support various industries.

The upgrades in 5-axis CNC machines are significant to the point that they’re almost different.

Aside from the X,Y, and Z axis, there are two additional axes which may help in shaping more complex parts. |

CNC Machines that have beyond 5-axis is an overkill for basic production.

They can offer extreme accuracy for complex parts.

Industries that need to create highly complex and precise parts can always benefit from these CNC machines.

These CNC machines may have 6-axis, 7-axis, 8-axis, and more. The higher the axis, the more accurate the parts will be. |

|

Advantages |

● The price is more affordable than the other multi-axis machines ● It has good precision as the basic multi-axis machine ● The tooling is simple enough to handle |

● Can produce angled features on a 2D base. ● It is more precise than the 3-axis CNC machines. |

● It may operate multiple facets on the workpiece, significantly increasing the production speed. ● May create 3-dimensional parts ● The cycle time is shorter ● The throughput is excellent ● Has better tool reach |

● Extreme accuracy compared to the other CNC machines with fewer axes. ● Machining time is cut in half. ● Production throughput can be doubled. |

|

Disadvantages |

● The machine can’t work on producing complex parts as it’s less accurate compared to the other multi-axis machines. ● Can not work on multiple workpieces ● Has slow manufacturing processes, which is not good for companies who need to maintain their production speed for bulk creation. |

● Doesn’t offer new advantages when compared to a 3-axis CNC machine

|

● The machine can be very costly. ● Needs frequent maintenance to keep it going smoothly ● Needs a highly experienced operator ● Requires much complex programming |

● Really expensive ● Requires more experienced operators and more complex programming in order to work properly. |

The multi-axis CNC machines may present various advantages to different industries. As the demand for better precision has increased, investing in multi-axis CNC machines may help to fulfil the demand with quality, more-precise products.

Using the axes that can work in multiple angles, it’s really possible to create highly precise parts. This technique may help in producing more complex parts required by various industries, including health, aerospace and aviation.

As one small error may result in a terrible outcome, the multi-axis CNC machines may help in providing the parts that are really precise and up to standard.

Additionally, the multi-axis CNC machines are also useful to simplify the production process as there’s no longer the need to prepare multiple setups for producing parts with different specifications.

Using only one machine, a company may create several parts using different designs. Its flexibility and versatility are second to none.

Another good thing multi-axis CNC machines can provide is better overall production efficiency. Using the machines may eliminate some issues regarding cycle times and the need to use multiple machining systems.

Just by using one machine, a company may have increased productivity as they can streamline the machining processes through a very effective method. With automation, it’s possible to maintain good production cycle in the long run.

Plus, it helps to reduce the risks of manual intervention. After the setup process is complete, the multi-axis CNC machine can work automatically to create parts accordingly.

With versatile axes, multi-axis CNC machines can produce complex parts that were previously nearly impossible in traditional CNC machines. This ability allows you to create precise models with detailed shapes and contours.

The simultaneously moving axes may also eliminate some problems regarding the cutting. As they are constantly moving, they can reach even the hardest area, making it possible to make details in every part.

The use of multi-axis CNC machines is limitless. The ability to craft complex parts is really useful in a lot of industries, including:

As these industries require parts with high precision, the multi-axis CNC machines can get the job done easily. Using their versatile axes, it’s really possible to create parts with the highest precision possible.

The multi-axis CNC machines have been used to craft the turbine blades, structural elements, and engine components of an aircraft.

The same thing goes for the automotive manufacturing industry where the parts should be precise according to the specifications. The machines help the industry by producing highly detailed parts, like transmission parts, engine components, and many others.

As this technology makes it possible to create intricate parts, machines can fulfil the needs effectively.

Yes, multi-axis CNC machines are also useful in the die-making industry. But in which way they are useful?

The CNC machines may help the industry by producing dies, tooling components, and molds that can be useful in other industries as well. The ability of multi-axis CNC machines makes it possible to create components and parts at constant quality and durability.

The multi-axis CNC machines are reliable in the health industry. The industry heavily relies on their ability to create the medical devices that are needed by many.

With exceptional precisions, multi-axis CNC machines are usable for some products, including prosthetics, surgical instruments, implants, dental appliances, and many others.

In order to ensure the machines run smoothly, you’ll have to understand a few challenges and conquer them.

The first and the most crucial one. The multi-axis CNC machines may not be affordable. With their performance and versatility, companies need to invest a good amount of money. However, we may have a solution for you. See at the end of the article for more info.

As there are so many processes involved in the multi-axis CNC machines, the programming is understandably complex as well. Thus, these machines will need some advanced programming in order for them to run and shape the parts as intended.

The programming has to be free from error as one small issue may cause malfunction or part errors.

Just like any machines out there, the multi-axis CNC machines also need regular maintenance. Therefore, the company must prepare a schedule for their maintenance. The correct maintenance may help to prolong the life of the machines as well as solve any possible issues.

With our 20+ years of experience in the business, we are capable of delivering excellent quality multi-axis CNC machines at competitive prices. Get the best of your CNC machines with our delicate services.

Our technical support will assist you not only with the CNC machines but also with the market, export, production, and many other aspects you want to know. Call us now for more info!