Stainless steel 304 is one of the most widely used stainless steel grades due to its excellent corrosion resistance and versatility. However, its toughness and tendency to work harden during machining present significant challenges for many manufacturers. Selecting the right CNC machine is crucial to ensure high productivity, precise finishes, and longer tool life when machining stainless steel 304.

At Yangsen CNC, we specialize in providing heavy-duty and high-precision CNC machining centers, turning centers, and vertical lathes designed to handle the demands of stainless steel and other hard-to-machine materials. Our advanced machines offer powerful spindles, rigid structures, and reliable control systems, making them ideal for processing stainless steel 304 efficiently and accurately.

Stainless steel 304 is renowned for its exceptional corrosion resistance and toughness, making it an ideal material for a diverse range of applications in food processing, medical devices, and chemical equipment manufacturing. However, these same properties that make it so useful also make it challenging to machine.

Firstly, stainless steel 304 has a high work hardening rate. When the material is cut, the area near the cutting edge becomes harder due to deformation, which increases cutting forces and accelerates tool wear. This can lead to poor surface finish, dimensional inaccuracies, and even tool breakage if improper cutting parameters or machines with insufficient rigidity are used.

Secondly, the toughness of stainless steel 304 results in higher cutting temperatures during machining. Excessive heat can degrade tool coatings, reduce tool life, and cause thermal expansion that affects part accuracy. Therefore, CNC machines with powerful coolant systems and stable temperature control are critical when machining this material.

Finally, stainless steel 304 tends to adhere to the cutting tool, leading to built-up edge (BUE) formation. This reduces cutting efficiency and deteriorates surface finish quality. Machines with high spindle power, rigid structures, and vibration-resistant designs can help maintain optimal cutting conditions and minimize these issues.

Selecting the right CNC machine for stainless steel 304 machining is essential to ensure high productivity, excellent surface finish, and long tool life. Here are the key factors you should consider when making your investment decision:

Stainless steel 304 requires high cutting forces, especially during heavy milling or deep cutting operations. Machines with a rigid structure and heavy-duty casting can effectively absorb vibrations and maintain stability under load. This prevents chatter marks, improves dimensional accuracy, and extends tool life. For example, Yangsen’s double column machining centers are designed with reinforced columns and bases to deliver maximum rigidity for tough materials.

Processing stainless steel 304 demands sufficient spindle power and torque to maintain consistent cutting performance without slowing down under load. Machines equipped with high-torque spindles can handle aggressive cutting parameters and reduce cycle times significantly. When choosing a CNC machine, always check the spindle motor specifications to ensure it meets the requirements of stainless steel machining.

Although stainless steel machining generally requires lower cutting speeds compared to aluminum, having an optimal RPM range is still important to achieve precise finishes and efficient material removal. Machines with flexible spindle speed ranges allow you to adapt to various tooling requirements, cutting depths, and part geometries effectively.

Due to the high heat generated during stainless steel machining, an effective coolant system is critical. Machines equipped with high-pressure through-spindle coolant systems help in flushing chips away from the cutting zone, reducing heat buildup, and improving tool life. Additionally, external coolant nozzles should be adjustable to direct coolant precisely where needed.

Stainless steel chips are tough and can easily accumulate around the workpiece or cutting tool if not properly managed, leading to tool damage and poor machining accuracy. Choose machines with efficient chip conveyors, chip flushing systems, and fully enclosed guarding to maintain a clean and safe working environment.

A powerful and user-friendly CNC control system enhances productivity by enabling complex programming, precise toolpath control, and real-time monitoring. For stainless steel machining, features such as adaptive control, high-speed processing, and accurate interpolation are beneficial to achieve optimal results.

By considering these key factors, you can ensure that your CNC machine investment delivers the performance, reliability, and precision required for successful stainless steel 304 machining. At Yangsen CNC, our machines are engineered with these requirements in mind, helping manufacturers achieve consistent quality and efficient production.

Selecting the right type of CNC machine is crucial for achieving the best performance and productivity when machining stainless steel 304. Below are the recommended CNC machine types based on part geometry, production volume, and machining requirements.

Vertical machining centers (VMCs) are widely used for machining stainless steel 304 parts, especially plates, blocks, and general-purpose components. They offer:

Advantages:

Easier workpiece setup and visibility

Effective for operations such as face milling, drilling, tapping, and contouring

Compact footprint suitable for most workshops

Recommended specs for stainless steel:

High-torque spindle with at least 15-18.5 kW motor power

Rigid column and base casting to reduce vibration

High-pressure through-spindle coolant system for efficient chip evacuation

Yangsen’s VMC series is engineered with heavy-duty designs and precision linear guideways, making them suitable for stainless steel machining with superior stability and accuracy.

Horizontal machining centers (HMCs) are ideal for stainless steel parts that require complex machining on multiple sides or deeper cavity milling. They provide:

Advantages:

Better chip evacuation due to horizontal spindle orientation

Higher productivity with multi-pallet systems

Excellent rigidity for heavy cutting of tough materials like stainless steel 304

Recommended specs:

Powerful spindle motor (above 18.5 kW) with high torque

Large work envelope to accommodate big stainless steel parts

Advanced coolant management and chip conveyor systems

For mass production or parts requiring multiple face machining, an HMC will significantly improve cycle times and reduce manual intervention.

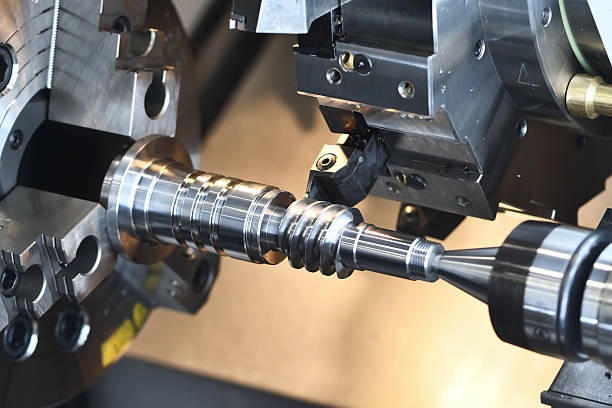

For shaft-type or cylindrical stainless steel 304 components, CNC turning centers are the optimal choice. They offer:

Advantages:

Precision turning of stainless steel with consistent surface finish

Capability to perform turning, drilling, and boring operations in a single setup

Optional live tooling and Y-axis for milling features

Recommended specs:

High spindle torque to handle stainless steel cutting forces

Rigid turret and heavy-duty bed casting for vibration resistance

Programmable tailstock or steady rest for long parts

Yangsen’s CNC lathes are designed with box guideways and powerful spindles, ensuring stability and performance when machining tough materials like stainless steel 304.

For large stainless steel molds, dies, or structural parts, double column machining centers provide unmatched rigidity and machining capacity. They are suitable for:

Heavy milling and deep cavity cutting in stainless steel

Maintaining dimensional accuracy on large workpieces

Applications requiring high spindle torque and structural stability

By choosing the right CNC machine type based on your part requirements and production goals, you can maximize efficiency, extend tool life, and achieve high-quality results when machining stainless steel 304. At Yangsen CNC, we offer a comprehensive range of vertical, horizontal, turning, and gantry machining centers to support your stainless steel machining needs.

Machining stainless steel 304 effectively requires a combination of the right machine, tooling, cutting parameters, and coolant strategies. Implementing best practices will improve surface finish, extend tool life, and enhance overall productivity. Here are key recommendations:

Stainless steel 304 tends to work harden quickly, increasing tool wear. To minimize this:

Use carbide tools with high toughness and heat resistance.

Select appropriate coatings, such as TiAlN or AlTiN, which provide better oxidation resistance and reduce friction.

Opt for positive rake angle inserts to reduce cutting forces and improve chip formation.

Maintain lower cutting speeds (SFM) compared to mild steel to reduce heat generation.

Example: ~150-250 SFM for carbide tools depending on operation and coolant application.

Use moderate feed rates to avoid tool rubbing and ensure effective chip removal.

Adjust depth of cut to maintain consistent engagement, avoiding shallow cuts that can promote work hardening.

Stainless steel machining generates high heat, which affects tool life and part accuracy:

Use high-pressure coolant systems (through-spindle if available) to flush chips from the cutting zone and reduce thermal buildup.

Ensure coolant is directed precisely at the tool-chip interface.

For drilling operations, peck drilling with adequate coolant can prevent chip packing and tool breakage.

Always keep the tool engaged in cutting; avoid dwelling or pausing mid-cut.

Avoid using dull tools, as they rub rather than cut, increasing work hardening risks.

Ensure proper machine rigidity to prevent tool deflection, which can cause inconsistent cutting depths and localized hardening.

Use machines with high structural rigidity, such as box guideway designs or double column structures, to handle the cutting forces of stainless steel without vibration.

Securely clamp the workpiece to prevent micro-movements that may lead to chatter and poor surface finish.

Inspect tools frequently for wear or chipping to maintain machining quality.

Keep machine spindles, guideways, and coolant systems clean and well-maintained to ensure optimal performance during stainless steel machining.

By applying these best practices in your stainless steel 304 machining operations, you can achieve superior surface finishes, maintain dimensional accuracy, and maximize your CNC machine’s capabilities. At Yangsen CNC, our machines are designed with the rigidity, spindle power, and coolant performance required to meet these demanding standards efficiently.

Machining stainless steel 304 presents unique challenges due to its toughness and tendency to work harden, but with the right CNC machine, tooling, and process strategies, manufacturers can achieve exceptional results. Selecting a CNC machine with high rigidity, powerful spindle torque, and effective coolant management is crucial for efficient stainless steel machining.

At Yangsen CNC, we offer a comprehensive range of vertical machining centers, horizontal machining centers, turning centers, and double column machining centers designed to handle the demands of stainless steel 304 with precision and reliability. Our machines are engineered to deliver consistent performance, superior surface finishes, and extended tool life, helping you maintain a competitive edge in today’s market.