In the last few decades, computer numerical control systems have been encouraged more in machining centers. They are commonly known as CNC machining. Due to its axis 1 to 5, their working capacity has improved in recent years.

The axis of CNC machining mostly ranges from 1 to 5 in machining centers. They assist in analyzing the exact range and difficulty of movements that the machine can perform and produce.

This axis as a tool in CNC machining helps in providing accurate and unmatched results with more efficiency. Moreover, the axis as a CNC machine tool provides versatility in producing better quality output.

The axis 1 to 5 plays a vital role in manipulating the tools with another axis for effortless functioning. All five axes work in different directions. They are also referred to as cutting tools for CNC machining.

These axes help in removing unnecessary material from the required product or tool. Besides, with the advancement in technology, the axis of CNC machining has also been innovated. Now, CNC machining centers can use them for huge cuttings and heavy projects. The progress in the axis is creating ease for the labor force by performing well and getting desired outcomes.

In this article, we will explore all the axes of a CNC machining center. We will also discover how they work and what their capabilities are. Let’s start with understanding the 5-axis CNC machine.

The key role of the axis in the CNC machining center is to determine the accurate direction and movement that the cutting tool performs.

These axes improve the working capability by providing results in 3D space. They accurately analyze the movement of the machine and present it in 3D motion.

Moreover, from 1 to 5, each axis plays a different and exclusive role while working with CNC machining. All the axis helps in enhancing the versatility level of machinery. This not only improves its working capacity but also enables it to produce complicated parts and tools. This axis 1 to 5 plays an important role in reducing setups and providing higher accuracy of tools.

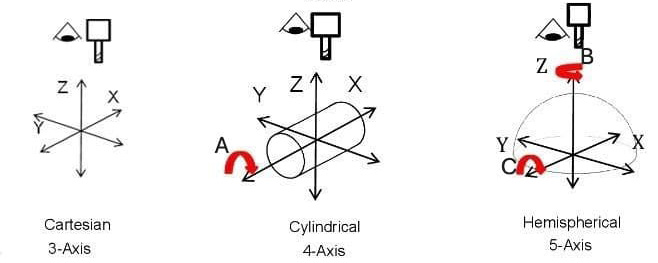

These axes are commonly designed in the following sequence.

The x-axis provides horizontal movement for the CNC machining in centers. Their working direction goes from left to right.

The y-axis of the CNC machining center also works in horizontal movement. But this axis works from front to back.

The z-axis provides vertical movement for the CNC machining center. Its direction is from up to down.

The A-axis provides rotational movement, and its movement works around the X-axis. You can count it as they work for each other.

The B-axis also provides rotational movement, but its movement works around the Y-axis. Just like the A-axis, the B-axis works for the Y-axis.

The C-axis provides rotational movement for the Z-axis. Its exceptional features include that you can find it in CNC machines with more than five axes.

All types of axis 1 to 5 play a vital role in performing the task and creating ease for cutting tools. These axes increase the accuracy of the final output.

Furthermore, they help in determining the directions of the movement and complexity of the final product they are producing.

It is better to explore more about this axis individually so we can understand its features and working capability. Let’s discuss them one by one.

The following are the axes of the CNC machining center that create ease in performing their complex and heavy tasks.

Axis 1 is referred to as a foundation for the CNC machining center. It is one of the simplest forms of the axis. This axis is capable of single movement while performing tasks. It usually moves around the X-axis.

Additionally, as its movement is simple and easy, it is mostly used for performing basic functions. Its most common tasks involve cutting hard materials and drilling in a straight line.

The following are its working applications in the CNC machining center.

● Axis 1 is mostly used for drilling purposes. It helps in drilling holes in different materials, including plastic, wood, and all types of metals.

● Besides, this axis also helps in creating simple cuts for workpieces.

Although Axis 1 is very important for CNC machining centers, it still has some limitations and these are as follows.

● Due to its simple working application, this axis is not suitable for complex geometric tasks. It does not support complicated procedures.

● It requires manual assistance while performing. For example, the operators need to change the direction themselves for repositioning the movement.

Following are the advantages of axis 1.

● Due to single movement, it is easy to handle it while performing tasks.

● It takes less time to perform.

● Due to its easy working, it is the most suitable tool for all operating team members.

The next axis of the CNC machining center, axis 2 helps in providing extra dimension for versatility. It helps in improving the working capacity.

This additional axis typically refers to the Y-axis. It helps in providing two-dimensional movements. It typically includes both the X and Y axis at the same time.

This multi-dimensional axis 2, enhances the working mobility of the machine. Moreover, it helps in handling more complicated tasks with more accuracy and in less time.

Following are the applications of Axis 2 for the CNC machining center.

● This type of axis helps in crushing and routing. It helps in producing 2D shapes. It includes pockets and slots.

● Axis 2 can perform well in limited space as well. Additionally, it can handle complex operations on a flat surface.

Besides its ease in the working process, Axis 2 also faces some limitations and these are the following.

● It only works with two dimensions, and this limits its working capacity.

The following are the benefits of axis 2.

● It helps in performing more complicated tasks as compared to axis 1.

● It does not require manual repositioning or assistance while working.

● Due to its two-axis movement, it allows complex movement for two-dimensional CNC machining.

Axis 3 also refers to the core for CNC machining center advancement. It provides upside-down movement while producing and performing tasks.

It is linked with the Z axis which helps in bringing the third dimension to the CNC machining proficiency. Furthermore, axis 3 is a fully functional dimension. This feature makes it suitable for all types of complicated applications.

Axis 3 helps in performing the following tasks.

● Axis 3 is famous for creating 3 dimensional (3D) shapes and outlines.

● Also, it helps in creating difficult designs and text on the surface.

● This axis is also used for manufacturing detailed models and their parts.

Like all tools, axis 3 also has some limitations and these are as follows.

● Axis 3 is not suitable for tasks that require undercuts.

● Besides, it cannot work well when tools need to be accessed from multiple angles. It has limited capacity for multiple angels at a time.

Although axis 3 faces some limitations it has some advantages as well.

● Due to its versatility, axis 3 can handle multiple tasks at the same time.

● It is suitable for both simple and complicated designs.

● In addition, this axis can perform multiple tasks without manual assistance.

The axis 4 of the CNC machining center is exceptional for its rotational feature. This rotating feature helps in producing accurate and defined results.

This fourth axis provides rotation for the X-axis. Moreover, this axis allows the tool to enter into another surface without any manual help. It helps in repositioning the workpiece effortlessly.

The fourth axis helps in performing the following tasks.

● The 4-axis is highly suitable for creating fine edges and angles smoothly.

● It helps in keeping the rotational balance as needed for performing the tasks.

● It performs multiple tasks in a single setup. It reduces the working time frame.

There are a few limitations for the fourth axis while performing tasks. These are as follows.

● The programming for axis 4 is complicated due to its advanced features. It requires deeper understanding.

● More skilled and qualified staff is needed to perform tasks with axis 4.

Following are the advantages of axis 4 of the CNC machining center.

● Its rotating feature reduces the repositioning which ultimately minimizes the setup time. It helps in completing the task quickly.

● With the advancement in working capacity, axis 4 enhances the machine’s ability to handle more complicated tasks effortlessly.

Axis five of the CNC machining center involves innovative technology for incredible performance. This tool helps in providing rotation around the Y-axis.

It helps in virtually repositioning the tools in the required direction. Additionally, axis five produces 5 axes for the CNC machining center for a more versatile type of production.

Following are the applications of axis 5.

● It is highly suitable for aerospace component productions.

● Axis 5 helps in producing high-tolerating and complex parts for advanced machinery.

● Besides, it is highly suitable for the production of medical instruments for higher accuracy.

● Machining tools that require complicated geometric settings can smoothly work with axis 5.

The following are the limitations for axis 5.

● The biggest limitation of Axis 5 is its high cost. It is the most expensive among all axis and is not affordable by all CNC centers.

● Due to innovative technology, it requires an experienced and highly qualified operating team.

● Besides the expert team, axis 5 requires updated software to perform accordingly.

The following are the advantages of axis 5.

● It is the most flexible tool that can virtually set the position of a surface or working tool.

● With advanced technology, it minimizes inconsistencies while performing tasks.

● It requires less time to produce complicated parts and tools as per instructions.

After analyzing the entire five-axis, let’s explore which axis is suitable for different tasks and performances.

While performing tasks with CNC machining, it is very important to know which axis is suitable for that specific task. Different axes perform differently and due to their distinct features, they perform likewise. It all depends on the nature of the project that needs the use of the required axis. Furthermore, it also depends on the complexity level during the production phase.

The following are the key elements that help in analyzing the suitable axis for performing the required task.

1. For simple tasks and production, axis 1 and 2 are highly suitable. While for complex manufacturing axis 4 and 5 are highly recommended.

2. Higher axes are more costly as compared to lower axis. Its expense cost is not limited to its purchase but is also linked with its operational activities. Additionally, the 1 and 2 axes require a lesser budget as compared to axis 3, 4, and 5.

3. A higher production level requires a higher axis. Moreover, it reduces its working costs. On the other hand, for low-level production, the 1 and 2 axes are more suitable.

4. Higher axes like 4 and 5 require an advanced type of material for production. It helps in enhancing its working capacity and versatility.

Now, let’s discover the future aspects of Axis for more innovative ideas.

Due to the advancement in technology and higher demand for innovative designs, the future of the axis for CNC machining centers is very bright.

All axis 1 to 5, paving a successful path for better and accurate outcomes for all tools. Besides, these axes are helping to introduce the new and advanced axis for more innovative outcomes. These axes are pushing the boundaries for impossibilities for CNC machining centers.

Following are the emerging advancements in the coming axis.

● More machines are designed with 6 axes and more for handling more complicated and advanced designs and procedures.

● The combination with robotic assistance is also expected in the future. It will help in the automated inspection process with loading and unpacking.

● Furthermore, the integration of artificial intelligence is also predicted for the advanced axis. It will include efficient programming for performing tasks without manual assistance.

The development of axis 1 to 5 shows its advancement and innovation in technology. From simple axis 1 to highly competitive axis 5, it represents the transformative power of CNC machinery centers.

As we mentioned above, each new axis comes up with more working capacity. Moreover, it helps in creating more possibilities for better and more accurate production levels. This axis helps the manufacturers in providing more complicated designs as required with a lower tolerance level.

By estimating the working capacity of axis 1 to 5, the producers can easily estimate the productivity level. Besides, it will help them increase the productivity level for advanced and innovative manufacturing. Lastly, due to continuous advancement in axis, the future of all and the coming axis of CNC machining is very welcoming.