Xi'an International Machine Tool Exhibition is an important machine tool industry event in western China, focusing on intelligent manufacturing, high-end equipment, precision machining and other fields, providing exhibitors and professional visitors with a platform for technical exchanges, trade cooperation and market expansion.

Exhibit Range:

Metal cutting machine tools: lathes, milling machines, grinders, machining centers, etc.

Forming machine tools: stamping, laser cutting, bending machines, etc.

Intelligent equipment: industrial robots, automated production lines, CNC systems.

Tools and accessories: tools, fixtures, measuring instruments.

Supporting technologies: CAD/CAM software, lubrication and cooling systems, etc.

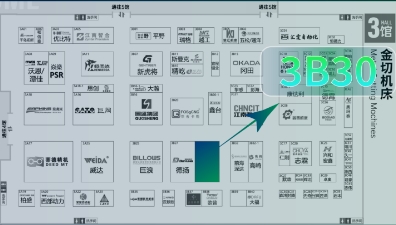

Yangsen Booth:

Our booth is Hall 3, 3B30. You are always welcome to visit us.

Exhibited Models:

Exhibited Models:

|

YSV-1060Z vertical machining center

The YSV-1060Z vertical machining center uses industry-famous brand components, is equipped with a high-torque high-speed motor, and has a super rigid bed design. It combines high torque, high speed and high precision, and is suitable for processing various products and molds. It meets the requirements of different industries for processing quality and efficiency, and is the only choice for high-speed precision mold machines.  |

YSCX-50CY Turning and Milling Compound CNC Lathe YSCX-50CY is a multifunctional power toolturret turning and milling compound machine (interpolation Y) developed by Jansen based on the standardized and modular design concept. The equipment adopts a 30° inclined bed structure with an interpolation Y-axis power mechanism to perform compound processing of turning, milling, and cutting products. It has compound functions such as turning, milling, and boring, and can realize the processing concept of one-time clamping and full completion.

|

YSH-800 horizontal machining center The YSH-800 horizontal machining center adopts a positive T-shaped main structure, a fully movable column structure, and good rigidity. It is suitable for complex processing of box-type parts. The tool can be automatically exchanged during the processing. It can be clamped once for milling, drilling, reaming, boring, reaming, and tapping on four surfaces. The modern machine tool and control concept, compact structural design, ensure high efficiency and high precision processing requirements for single or small and medium batch products.

|