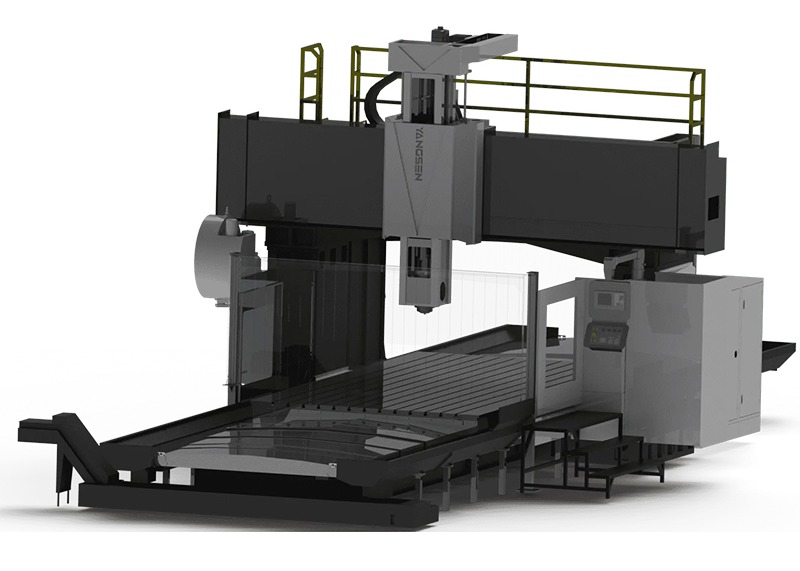

Getting a gantry type CNC machine is an excellent idea to boost efficiency and productivity. You always want to focus on quality and value; doing that will offer exceptional results and a wonderful experience. With that in mind, gantry milling machines have a gantry frame and a horizontal, long bed. A gantry CNC machine is different because its surface can be machined with various cutters.

The CNC gantry milling machine is excellent for working on larger workpieces with 5 sides or more. The large gantry CNC machines offer you the capacity to do all of this within a single setup. These machines also provide multitasking features, including laser hardening, grinding, turning, milling, and even drilling.

Learning how to choose a gantry CNC machine

The challenge of picking a gantry type CNC machine is that you can find many different options on the market. With so many different features to look for, it becomes very difficult to narrow down the exact things you should be looking for. When you try to buy a gantry CNC machine from a reliable CNC gantry machining center, these are all the different features you want to consider!

Gantry configuration types

What many people don’t know about a CNC gantry milling machine is that there are different models to choose from here. The 3-axis CNC model usually comes with the X, Y, and Z axis; each one is adjusted to fit requirements and needs accordingly. You can also find larger models with multiple axis features. Then there are also fixed and moving gantry models.

Fixed gantry

The fixed gantry is a very common gantry machine and its efficiency comes from stability and reliability. It stays in a single place, which is very helpful because you can work on your project within the premises. There’s no need for mobility, however this is ideal for smaller pieces.

Moving gantry

If you need portability or have the opportunity to work on larger models, a moving gantry becomes necessary. Fixed gantry models are great for smaller projects, but sometimes you need a moving gantry machine to work on larger items.

A moving gantry’s X and Z axis are on a gantry beam. It’s that beam which moves in the linear Y direction. It’s helpful because it adds more functionality without restricting you in any way. Instead, you have the freedom to move your machine and adapt it to your particular project.

With that in mind, the piece you are working on is set directly on the table, and the table itself is stationary. Here just the gantry beam moves, and it all follows your chosen design.

Things to look out for when buying a gantry CNC machine

The purchase of a gantry machine is very tricky, since you always want to ensure you buy the right model. Aside from the gantry machine type, there are a variety of features you need to think about as well. Here are some of the most important ones!

Build complexity

When you want to choose a gantry type CNC machine, build complexity is undoubtedly one of the deciding factors. A fixed gantry has limitations since you don’t have many moving parts. A moving gantry is mechanically dependent on components, but it offers a lot more variety and still delivers an exceptional result. That’s why we highly recommend going for a moving gantry 5 axis CNC machine, as it’s usually the best option on the market. Then we have to think about rigidity too.

Our Products

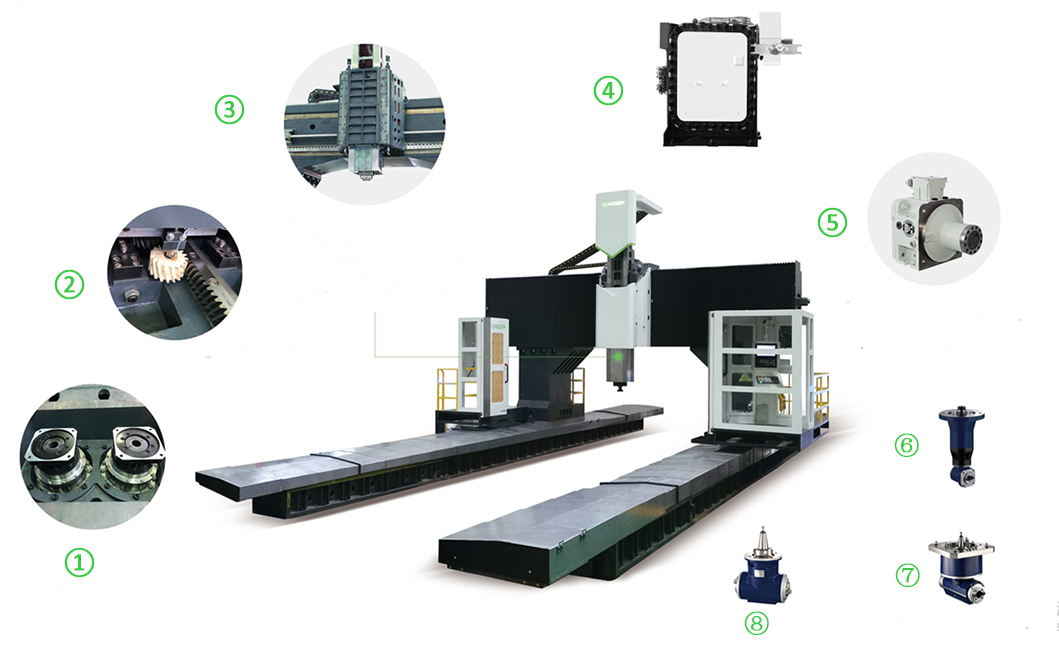

YSM23/27 Series: 2-line tracks and 1-hard rail.

| Model | YSM-2013 | YSM-2015 | YSM-2217 | YSM-2518 | YSM-3018 |

| Travel X/Y/Z mm | 2000/1300/800 | 2000/1500/800 | 2200/1650/800 | 2500/2000/960 | 3000/2000/960 |

| Model | YSM-3023 | YSM-4023 | YSM-4027 | YSM-6027 | YSM-4027Ram |

| Travel X/Y/Z mm | 3000/2300/1000 | 4000/2300/1000 | 4000/2700/1000 | 6000/2700/1000 |

4000/2700/1000 Optional 1250 Z axis |

| Model | YSMV-2013 | YSMV-2817 | YSMV-3021 |

| Travel X/Y/Z mm | 2000/1300/800 | 2800/1900/800 | 3000/2600/1000 |

| YSMV-5021 | YSMV-3027 | YSMV-5030 | YSMV-7030 |

| 5000/2600/1000 | 3200/3000/1300 | 5000/3200/1300 | 7000/3200/1300 |

| Model | YSM-3028 | YSM-5028 | YSM-7028 | YSM-5032 | YSM-7032 | YSM-9032 |

| Travel X/Y mm | 3000/2800 | 5000/2800 | 7000/2800 | 5000/3200 | 7000/3200 | 9000/3200 |

| Z mm | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) |

| Model | YSM-5038 | YSM-7038 | YSM-9038 | YSM-5042 | YSM-7042 | YSM-9042 |

| Travel X/Y mm | 3000/3800 | 5000/3800 | 7000/3800 | 5000/4200 | 7000/4200 | 9000/4200 |

| Z mm | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) | 1000 (Optional 1250, 1500) |

YSMD Series:

| Model | YSMD-6042 | YSMD-8042 | YSMD-10042 | YSMD-12042 |

| Travel X/Y/Z mm | 6000/4200/1500 | 8000/4200/1500 | 10000/4200/1500 | 12000/4200/1500 |

| Model | YSMD-14042 | YSMD-16042 | YSMD-18042 | YSMD-21042 |

| Travel X/Y/Z mm | 14000/4200/1500 | 16000/4200/1500 | 18000/4200/1500 | 21000/4200/1500 |

| Model | YSMD-6046 | YSMD-8046 | YSMD-10046 | YSMD-12046 |

| Travel X/Y/Z mm | 6000/4600/1500 | 8000/4600/1500 | 10000/4600/1500 | 12000/4600/1500 |

| Model | YSMD-14046 | YSMD-16046 | YSMD-18046 | YSMD-21046 |

| Travel X/Y/Z mm | 14000/4600/1500 | 16000/4600/1500 | 18000/4600/1500 | 21000/4600/1500 |

Can you cut heavy parts?

Heavy parts can be challenging to cut when you have a fixed gantry CNC machine. Such items can benefit from a moving gantry machine because it can allow you to move the item around. As you do that, you can entirely cut everything and eliminate any possible problems or issues that can sometimes arise in these situations.

How accurate is the CNC machine?

Sure, even if the device is able to cut heavy parts, you still want to see whether it can do that accurately. A gantry CNC machine is usually very accurate, but you’re getting more accuracy with a fixed unit. Due to the moving parts, a moving gantry is not always offering the accuracy you want. Yet it’s still an exceptional solution, especially if you want to cut thicker materials. Plus, the ability to move that cutting head around is undoubtedly convenient. Yet, if you want to focus on accuracy, a fixed gantry type CNC machine is usually the better option.

Maintenance requirements

Maintenance is another major aspect when it comes to choosing a gantry CNC machine! A lot of people might overlook maintenance for an excellent reason. In most cases, the focus is on speed and quality, not on repairs or preventing any repairs in the first place. With that in mind, understanding maintenance requirements is very important, and that’s undoubtedly a thing to keep in mind.

Generally, the more moving parts you have for your gantry type CNC machine, the more maintenance you need. That’s why fixed gantry CNC machines tend to require less maintenance. That doesn’t mean it’s mandatory; however, you will notice that fixed gantry machines are usually the top option you need to keep in mind. With that in mind, complexity can be a factor.

It would help if you saw whether a more complex machine is necessary for you or not. Sticking to a more straightforward unit is usually the better option, and it will offer you a much better outcome. But remember, moving gantry models can deliver more flexibility, so you are getting both pros and cons, which is something to consider when buying this type of product.

One or two motors

Another thing you want to think about here is whether you want to go with one or two motors. That’s the challenge; a single motor comes with ease of use, whereas twin motors can bring more difficulty.

It is harder to track and manage, but you also need synchronization when you have two motors. While not impossible, it certainly adds that immediate sense of difficulty, and in the end, you will have a much better option if you stick with something simpler. Power is always important, sometimes you do need the 2 motor units. However, that might be pricey, and that’s why we think that pricing is just as important as many of the features shown here!

Pricing

Depending on the company which offers these CNC machines, you will have different price points. That’s the important thing here; you always have to be sure that you receive exceptional value for money. A gantry type CNC machine is expensive to begin with, but depending on your requirements, you will have some options that are cheaper than others.

According to our experience, fixed gantry CNC machines are usually cheaper. A moving gantry usually can have twin motors, which alone adds to the total costs. Then we also have moving parts, complex repairs, and extra maintenance. All of these things add up when it comes to the total costs.

As we know, each user has their requirements from a CNC gantry milling machine. But in the end, pricing will always matter, so you want to go with the best price possible. Sticking to your budget is a perfect idea, especially when there are so many different options to keep in mind. And once you try these for yourself, you will be thrilled with the experience and quality. Aside from price, you also want to see whether this is a rare product or not. Because there will be times when you want to find spare parts, and that’s certainly something to think about here.

Spare parts

Are spare parts easy to find or not? The truth is that many times you will end up trying to find spare parts, but those are not available. That’s the challenge; you always want to check the market and see if there’s spare part availability.

Power consumption

Power consumption can also be an essential factor if you have limited power within your work environment. Generally, you want to check and see power requirements, and then you can adjust the workspace. Either that, or you buy a gantry CNC machine that fits your power system. Power, just like speed, will always be major factors when it comes to selecting a powerful and easy to use gantry CNC machine!

Machine speed

Lastly, you want to see how fast the gantry CNC machine really is. Why is the feed rate significant? Feed rates will determine the overall speed of your manufacturing process. If you have a low feed rate, that becomes an issue. In this case, a quick feed rate is always the preferable option.

Conclusion

We believe it’s an excellent idea to assess all possible options and features before you buy a gantry type CNC machine. You never know what kind of tasks you need, so getting the best CNC machines is always going to help save both time and money. Xiamen Yangsen CNC Equipment Co., Ltd is here to help, and we can assist with top-of-the-line gantry CNC machine options fast and efficiently. All you need is to contact us today and pick the right gantry CNC machines that fit your needs!