Dear partners, I wish you a happy Chinese New Year and all the best. Don't forget to maintain the machine tool during the holidays.

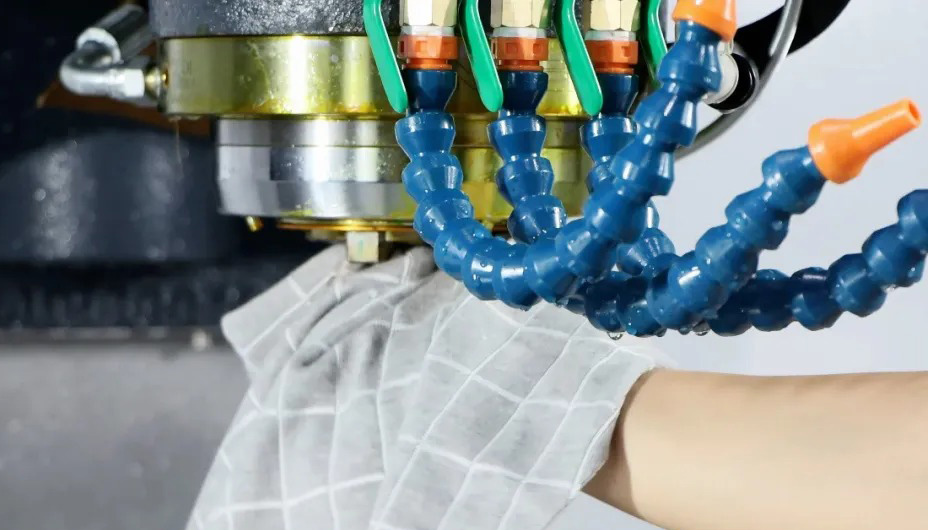

Clean the internal and external accessories of the machine tool, keep the machine tool clean and tidy, remove the iron chips, remove the workpiece fixture and chip conveyor, and clean the iron chips around the machine tool. Thoroughly clean the spindle taper, tool head, taper handle, tool magazine tool arm, and tool cup. Wipe the external sheet metal of the machine tool and wipe the system panel with industrial alcohol. Clean the oil cooler filter, electrical control box, system cooling fan port, and water pump cooling hole.

|

|

|

Inspection: Observe the lubricating oil, cutting fluid, and oiler oil in the knife cylinder, and clean the oiler cavity. Rust prevention: Clean the surface of the workbench and apply anti-rust oil; wipe the spindle taper with a clean cloth or paper towel, wipe the surface of the taper with lubricating oil, clean the tool and tool handle with gasoline and install them in the taper; the machine tool runs slowly throughout the process to lubricate the screw rod and linear rail. Oil filling: Inject an appropriate amount of oil into the tool cylinder, oiler, tool magazine oil filling point, oil cooler, etc. Cover: Cover the top of the water pump to prevent debris from entering.

|

|

|

Move the X and Y axes to the middle and the Z axis to the lowest point. Turn off the main power switch of the machine tool and the voltage regulator inlet switch. Cut off the gas source.

Moisture-proof and dust removal

Ensure that the workshop remains dry and dust-free during the shutdown of the machine tool. The electric control box needs to be closed and strengthened for protection. If conditions permit, a desiccant can be placed in the electric control box. The machine tool can be shielded by a protective cover to avoid direct sunlight and effectively prevent damage to electrical components and circuit boards.