In modern manufacturing, Computer Numerical Control (CNC) machines stand as cornerstone technology. Among CNC systems, the debate surrounding 3-axis vs 4-axis vs 5-axis CNC systems has gotten attention in recent years. These three methodologies represent distinct approaches to achieving precision, efficiency, and versatility in the machining process.

They all have their use, advantages, and disadvantages. Let’s take a look at them in detail.

So, Let’s dive in!

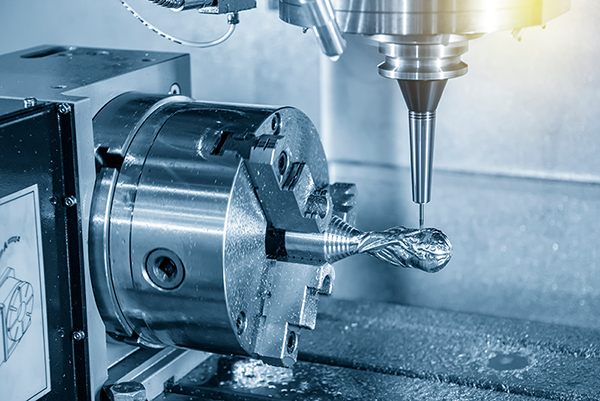

CNC stands for Computer Numerical Control. It's a technology that uses computers to control machine tools, such as lathes, mills, routers, and grinders. CNC machines translate digital instructions into precise movements, allowing for the automated fabrication of parts and components with high accuracy and consistency.

In CNC machining, designers create a digital model of the part they want to produce using Computer-Aided Design (CAD) software. This digital model is then converted into instructions, often in G-code, which specifies the exact movements and operations required to fabricate the part.

The operation of CNC solely depends on computer numerical control and coding. Meticulous programming is pivotal in controlling the tools and the inbuilt parts. Hence, you need to feed the Machine with the correct set of codes and instructions to make the Machine perform a specific task. The Machine, in turn, interprets the codes and performs the task accordingly. The automation feature ensures that the Machine continues the task until it is fully executed. Most importantly, it does not require the manual operator to perform the execution and thus saves time and energy. It is gaining prominence in various industrial sectors like aerospace, automotive, Motorsports, computer hardware manufacturing, toolmaking, etc.

Countless industries have become dependent on CNC owing to the multiple benefits involved in its usage:

●Enhancement of level of productivity

●Improvement of accuracy level of performance of machines

●Reduction in expenses in the process of production

●Acceleration of speed in the process of production

●Broadening of scope of utilization of various materials

●Reduction of dependence on manual operation

Different Types of CNC Machines

Having stressed the basic concept of CNC and its benefits, it is crucial to shift to the different types of CNC machines. Here I will further elaborate on the differences between these different types of CNCs, but before that, let us first understand each of their features. The three types are 3-axis, 4-axis, and 5-axis CNC machines.

Before delving into the different types of CNC machines based on axis, it is crucial to address the question of what is an axis.

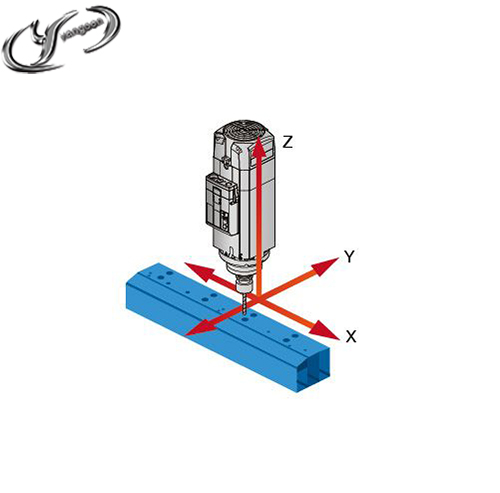

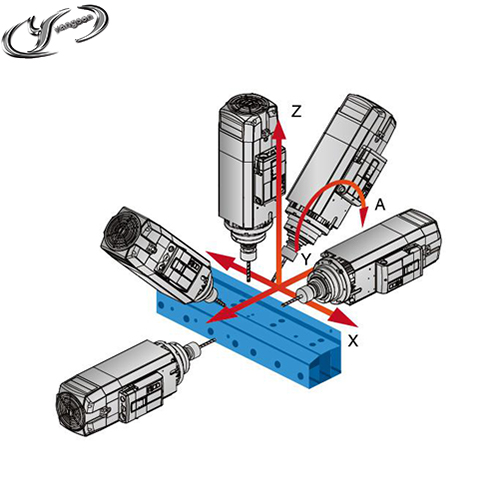

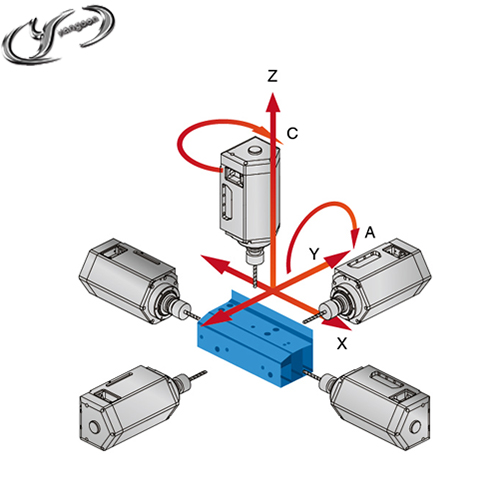

Axis is the imaginary line used for measuring coordinates and the term is used in defining a point in the spatial dimension. The horizontal and vertical planes are defined using X and Y axes while three-dimensional depth is defined using the Z axis. In the case of machinery, the Z axis refers to the rotational axis. While studying CNC machines, the linear axes stress the direction and movement of the machine. For instance, in the case of 3axis machines, the spindle moves up, down, and side to side to right; for 4-axis machines, it moves up, down, side to side, and has rotational movement; for 5-axis machines, it moves up, down, side to side, and has two rotational movements.

In CNC machines the standard three axes are X-axis (where the movement is from left to right), Y-axis (with movement forward-to-backward), and Z-axis (up-and-down). Thus, by utilizing these three axes, the CNC machine can drill any workpiece for creating three-dimensional items. However, it cannot handle any intricate or advanced design as those additional axes or complicated movements are required. For instance, in 5-axis machines, there are added axes like A-axis (rotating around the X-axis), B-axis (rotating around the Y-axis), and C-axis (rotating around the Z-axis).

A 3-axis CNC machine refers to a computer-controlled machining system that operates along three axes: X, Y, and Z. These axes represent three-dimensional space, with X and Y controlling horizontal movements and Z controlling vertical movement.

In a 3-axis CNC system, the cutting tool or workpiece can move in three directions to perform various machining operations such as milling, drilling, and cutting. This type of CNC machine is widely used in manufacturing industries for producing various parts and components, ranging from simple to moderately complex geometries.

While 3-axis CNC machines offer versatility and efficiency in many applications, they have limitations when it comes to machining highly intricate and complex parts that require multiple angles of approach. As a result, they may require repositioning of the workpiece or tool, which can increase machining time and complexity.

Despite these limitations, 3-axis CNC machines remain popular due to their relatively lower cost, simplicity of operation, and ability to handle a wide range of materials and part geometries. They are suitable for applications such as prototyping, general machining, and the production of parts with moderate complexity. However, for more complex geometries and advanced machining requirements, such as aerospace components or intricate molds, manufacturers may opt for more advanced systems like 5-axis CNC machines.

The first type is 3-axis Machines that serve well for flat surfaced workpieces. Again these are the ones that are easily affordable and are utilized for pieces that do not involve intricate detailing. For handling smooth 2D to 2.5D parts, you can resort to 3-axis machines. These are mainly used for drilling, tapping holes, flattening surfaces, and cutting sharp edges, and as the name suggests, these machines can cut across three axes of X, Y, and Z seamlessly.

●It can cut through three axes -for instance, X defines the width, Y indicates the length, and Z points out the depth.

●It can be used to move back-to-forth, side-to-side, and up-to-down.

●The Machine ensures the removal of unwanted portions of the workpiece and thus allows molding it in the desired shape and size.

●Mechanical parts and components can be manufactured easily using these machines

●It is user-friendly and has no added complexities in handling

●It is pocket friendly and can be used by newcomers in the business.

●The simultaneous movement of the 3 axes ensures the execution of multiple tasks

●The speed of task execution saves time and energy in molding the pieces.

●It allows room for the addition of more axes based on the machining center and thus leaves scope for upgradation

A 4-axis CNC machine is a type of computer numerical control (CNC) machine equipped with four axes of motion control. In contrast to the standard 3-axis CNC machines which can move along the X, Y, and Z axes, 4-axis machines add another axis of rotation, typically around the X, Y, or Z axis. This additional axis enables the machine to perform more complex machining operations and produce intricate parts with greater efficiency and accuracy.

The fourth axis of rotation allows the cutting tool to approach the workpiece from different angles, enabling operations such as indexing, contouring, and helical milling. This versatility is particularly beneficial for machining cylindrical or prismatic parts with features that require machining from multiple angles.

Applications of 4-axis CNC machines span a wide range of industries, including aerospace, automotive, medical, and mold-making. They are commonly used for tasks such as engraving, carving, drilling holes at various angles, and machining complex contours. Additionally, 4-axis machines can improve productivity by reducing the need for multiple setups and manual repositioning of the workpiece.

Overall, the incorporation of a fourth axis into CNC machining opens up new possibilities for manufacturers seeking to push the boundaries of precision and complexity in their production processes

●It allows cutting the workpiece as it is without dismounting it.

●You can easily remove the materials from either side owing to the rotational feature; thus, the molding can be done with better efficiency.

●It cuts down the cost of production and proves to be pocket-friendly in the business endeavor

●It improves efficiency and quality of execution of the tasks is more accurate

●The feature of cutting on different angles saves time and makes the task easier

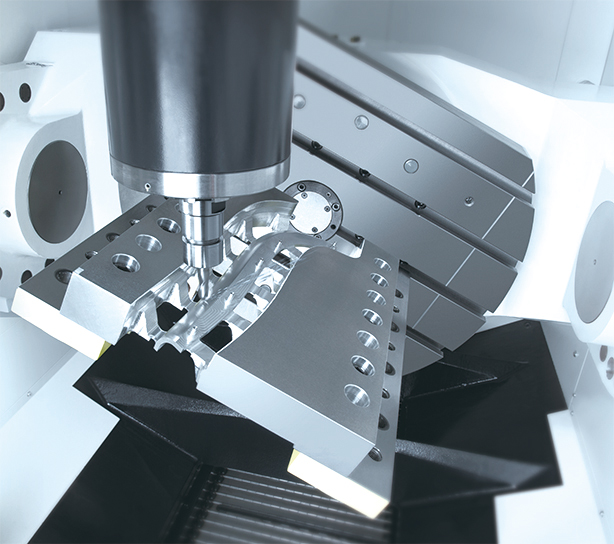

A 5-axis CNC machine is a sophisticated machining system capable of movement along five axes simultaneously: X, Y, Z, and two additional rotational axes, typically referred to as A and B. This additional freedom of movement enables the cutting tool to approach the workpiece from multiple angles and orientations, allowing for highly complex and intricate machining operations.

The primary advantage of a 5-axis CNC machine is its ability to produce parts with complex geometries and contours that would be challenging or impossible to achieve with traditional 3-axis machining. By tilting and rotating the workpiece or cutting tool, 5-axis CNC machines can precisely access difficult-to-reach areas and execute intricate tool paths.

These machines are extensively used in aerospace, automotive, medical device manufacturing, and mold making, where the production of complex components with tight tolerances is essential. Examples of parts commonly produced on 5-axis CNC machines include turbine blades, impellers, aerospace components, sculpted surfaces, and intricate molds.

The versatility and flexibility offered by 5-axis machining translate into several benefits, including reduced setup times, improved surface finish, higher accuracy, and enhanced productivity. Additionally, 5-axis CNC machines can streamline production workflows and optimize machining processes by minimizing the need for manual repositioning of the workpiece.

While 5-axis CNC machines offer unparalleled capabilities, they also come with higher costs and technical complexities compared to their 3-axis counterparts. Programming and operating these machines require specialized skills and expertise, and the initial investment and maintenance costs can be significant.

This is the most efficient CNC machine version due to extra rotation features on the two axes. However, the price of these machines is higher due to the added features. The accuracy and efficiency are highly evident in 5-axis machines with several unique features.

It includes A-axis rotation or rotation on the X-axis, much like a 4-axis machine, along with rotation on the Y-axis, which is referred to as the C-axis. 5 axis machines are of two types, namely

●3+2 Machine that includes rotation on two independent axes instead of simultaneous rotation.

●Fully Continuous Machine where simultaneous rotation on two axes is evident.

5-axis machines possess the added feature of another rotating axis, the B-axis. In this case, the X-Y-Z-A-B, or X-Y-Z-A-C, goes around the X, Y / X, and Z axes. 5-axis machines also enable the performance of intricate angles and cuts and confer a better finishing to the molding process as the 5-axis allows movement of the workpiece in different directions. You can make the cuts in full range, even in one operation. You can also delve into a myriad of design options owing to the presence of the 4th and 5th axes; thus, it enhances the range of designs that can be achieved by adding a tool head.

●It allows operation from five sides

●It allows the selection of two axes out of three rotational axes based on the type of Machine

●Here, the rotation is either on A and C axes or on B and C axes

●The CNC programming takes time

●The workpiece or the spindle performs the rotation

●It can be used to create 3D shapes using the continuous 5-axis

●It allows operation on the workpiece on five sides

●It allows working on complex materials seamlessly

●It can be used to execute detailed and intricate molding

If you are looking for efficient 5-axis CNC machines, you can check the leading manufacturers who produce these products and guarantee efficient operations. One such leading company is Yangsen which specializes in machine tools and is highly reputed for offering cutting-edge technology. The company provides high-quality products at affordable prices and exports its goods worldwide, and its 20 years of experience make it a reliable name in CNC machining.

The top two 5-axis machines manufactured by Yansen are:

What are the Differences Between 3, 4, And 5 Axis CNC Machining?

Having explained the key features of the three types of CNC machines, I will illuminate the significant differences between these products.

| Feature | 3-Axis CNC Machine | 4-Axis CNC Machine | 5-Axis CNC Machine |

| Number of Axes | 3 (X, Y, Z) | 4 (X, Y, Z + Rotary Axis) | 5 (X, Y, Z + 2 Rotary Axes) |

| Motion Capabilities | Linear motion along the X, Y, and Z axes | Linear motion along X, Y, and Z axes + Rotation around one additional axis | Linear motion along X, Y, and Z axes + Rotation around two additional axes |

| Complexity | Simple programming and operation | More complex programming required due to additional axis. | Requires advanced programming and expertise. |

| Precision | Good for basic machining operations | Offers improved precision and surface finish compared to 3-axis machines. | Provides superior precision and surface finish due to increased machining freedom. |

| Accessibility | Access to certain areas may be limited | Access may be restricted due to the added rotary axis. | Enhanced access to complex geometries and features with greater flexibility. |

1. Expenses-Here it becomes evident that the product's price is directly proportional to the number of axes. Hence the 5-axis machines have the greater manufacturing cost, and their operation involves greater expenses than their 3-axis and 4-axis counterparts.

2. Features- The features of the three types of machines also depict stark differences. For instance, the angled feature does not apply to the 3-axis machines. Similarly, 4 axis machines come with 3 axes and one rotation on the X-axis as an additional feature. Again, the 5 axis machines easily handle complex angles and comprise three axes and additional rotations.

3. Axis Movement- In the case of 3 axis, we observe three movements: up-down, left-right, and front-back. The 4-axis witnesses three axes movement teamed with one rotational movement while three axes movement and two rotational movements are observed in 5 axis machines.

4. Efficiency- The 3-axis machines have the lowest level of efficiency and accuracy, while the productivity of the 4-axis machines is higher than the former. However, the highest efficiency and accuracy of task execution are evident in the 5-axis machines, along with the ability to handle complexities and intricate tasks.

5. Applications- The 3 axis machines are primarily used to cut the sharp edges of workpieces, drill holes and milling slots, and initiate automation. If you are using high-volume parts, you can resort to 3-axis machines and put them into use for cutting out key slots or grinding. However, if you want to use the 3-axis Machine for a greater angled feature, it would necessitate intense planning. Although the process would become complicated, requiring constant mounting and remounting, you can get it done using 3-axis machines.

On the other hand, the 4 axis machines are mainly used for molding cylindrical substances or on multiple surfaces. The CNC mill gathers the qualities of the CNC lathe by adding the rotating axis. For seamless functioning on cylindrical surfaces, the workpiece and the cutting tool may be subjected to rotation. Again, you can only remount the material once for operating on a block and engraving identical features on all surfaces. Instead, the 4-axes can make your task easier. In such a situation, you must subject the workpiece to rotation to the next surface, cut the feature on it, and move to the next surface. Hence it saves time and effort.

Finally, the 5axis machines are the most effective and productive; they are used in the medical, aerospace, oil and gas, and mechanical part manufacturing industries. It is ideal for handling complex and high-grade machinery. In the case of the 5-axis CNC machines, it is observed that the material/workpiece can be rotated in every possible direction. Thus, the operation possibilities also increase, thereby allowing the engraving of complex designs without the hassle of remounting.

If you are facing confusion regarding choosing between these different types of machines, you may consider the factors -budget and requirement. If you are ready to invest and require a highly efficient and advanced machine then without any doubt 5-axis machine should be the top choice as it comes with greater flexibility than a 4-axis machine and promises more accuracy than a 3-axis machine. Moreover, it allows advanced-level programming of complex parts with a 5-axis VMC, unlike a 4-axis one. On the other hand, if you are adhering to a strictly lower budget and seeking something less complicated, it is wise to opt for 3-axis or 4-axis machines.

Parting Thought

This article highlights the different types of CNC machines and the differences between the 3–axis, 4-axis, and 5-axis machines and their features. If you plan to invest in these CNC machines, you can resort to reliable names like Yansen and check out their website for more details.