India's emergence as a prominent manufacturing hub for CNC machine tools, Vertical Machining Centers (VMCs) in particular, has occurred at a breathtaking pace. Precision manufacturing in modern industries cannot run without these machines. VMC machines are highly referred to in different industries like automotive, aerospace, electronics, mold making, defense, and general engineering due to their accuracy and repeatability, alongside supporting automated production workflows.

Many VMC manufacturers in India made great advances lately concerning productive and advanced spindle technologies, rigid machine structures, improvements in thermal stability, and even Industry 4.0-ready control systems. All these developments make local manufacturers very much comparable to world brands, but still provide economically good and service-friendly solutions suitable for Indian conditions.

Increasingly, with increasing demands on productivity, precision, and automation, it has become clearer that selecting an appropriate VMC manufacturer has turned into a strategic decision for manufacturing organizations of all sizes. Therefore, this article talks about the compiled list of the top manufacturers of VMC machines in India and their capabilities, product strengths, and relevance in different types of industries.

|

Brand Name |

Founded (Year) |

Headquarters |

Special Features |

|

Jyoti CNC Automation Ltd. |

1989 |

Rajkot, Gujarat, India |

Wide VMC range with a strong service network and Industry 4.0 solutions |

|

Lokesh Machines Ltd. |

1983 |

India |

VMCs are automotive-oriented, highly reliable, and perform to OEM trust. |

|

Ace Micromatic Group |

1973 |

India |

Integrated machining ecosystem, automation & Industry 4.0 |

|

BFW India (Bharat Fritz Werner) |

1961 |

India |

High-precision VMCs, smart manufacturing, aerospace & defense focused. |

|

Macpower CNC Machines Ltd. |

2003 |

Rajkot, Gujarat, India |

Precision VMCs, automation-ready, iso-certified manufacturing. |

|

Yangsen CNC |

2003 |

India |

Cost-effective VMCs, rigid structure, customizable automation |

|

Jaewoo Machines Ltd. |

1992 |

India |

High rigidity VMCs, mass production-conducive, Industry 4.0 ready. |

|

Tirupati CNC |

1998 |

India |

Robust VMC drilling machines, customized CNC solutions |

|

J.S. Engineering Works |

1983 |

Patiala, Punjab, India |

Precision machining assistance of SPMs, CNC & VMC functions. |

|

Shree Yantra Solutions |

2011 |

Bengaluru, Karnataka, India |

Industrial VMCs market, DRO & CNC accessories. |

|

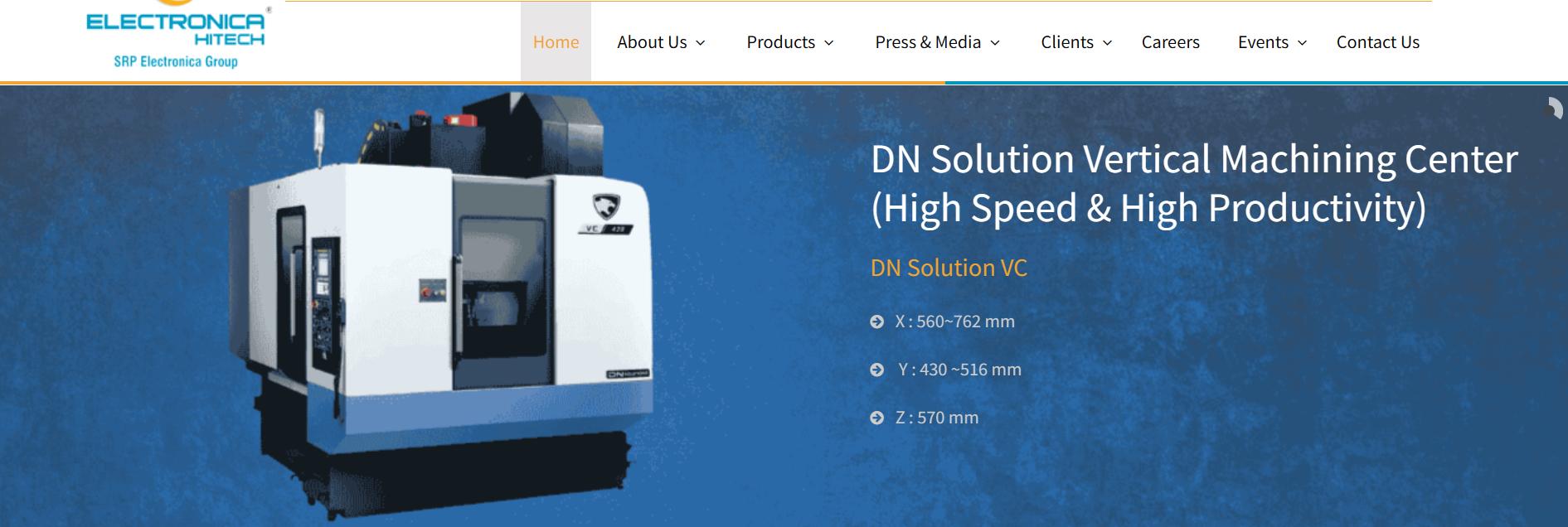

Electronica HiTech Ltd. |

2011 |

Pune, Maharashtra, India |

Superior-grade VMCs, double-column machines with good after-sales support. |

|

OM CNC Automation |

2021 |

Rajkot, Gujarat, India |

Value-driven VMC drilling machines, customer-centric CNC solutions. |

Type of Business: CNC Machine Tool Manufacturer and Automation Solutions Provider.

Year Established: 1989

Manufacturer Introduction:

Founded in 1989 with headquarters in Rajkot, Gujarat, it has grown from conventional machine manufacturing to being a global provider of CNC technology.

Jyoti CNC Automation Limited is credited as one of the oldest CNC manufacturers based in India, providing all-around reliable and precise machining solutions.

With installations extending across more than 60 countries, Jyoti CNC supports industries that need accuracy, productivity, and long-term operational stability.

Business Scope:

• CNC Turning Centers and Turn-Mill Centers

• Vertical Machining Centers (VMC)

• Horizontal Machining Centers (HMC)

• 3-Axis and 5-Axis CNC Machines

• Industry 4.0 CNC Automation Solutions

Recommended Reason:

Jyoti CNC Automation Limited is a good option for VMC. Their products have a wide range and have a strong domestic service network, as well as a global manufacturing base, making them suitable for both growing and mature industrial operations.

Type of Business: Manufacturing of CNC machine tools and special-purpose machines for automotive and general engineering industries.

Year Established: 1983

Manufacturer Introduction:

Lokesh Machines Limited is one of India's major brands in CNC manufacturing that came into existence in 1983.

The company is recognized among the top five machine tool manufacturers in India, catering mainly to the automotive sector and industrial applications.

Lokesh supplies more than 800 CNC machines every year with an emphasis on long-term accuracy and reliability.

Their machines are quite popular with major OEMs and auto component manufacturers, both in India and overseas. The company also exports CNC machines to Europe and other parts of the world.

Business Scope:

• CNC Turning Centers and Vertical Machining Centres.

• Horizontal Machining Centres and Vertical Turning Lathes.

• Special Purpose Machines for automotive.

• Application automation solutions, including gantry and robotic systems.

• Auto components like engine blocks, heads, and connecting rods.

Recommended Reason:

Lokesh Machines Limited is a strong choice for manufacturers who are looking out for reliable CNC machines with established performance in automotive and industrial applications. Such an advantage, coupled with the long industry presence of Lokesh, gives more assurance to the buyers in such machines that are just long-lasting and accurate.

Type of Business: Integrated machine tool manufacturing group providing CNC machines, automation systems, and smart manufacturing solutions.

Year Established: 1973

Manufacturer Introduction:

Ace Micromatic Group is the biggest Machine Tool conglomerate in India and has been providing comprehensive machining solutions since 1973.

The group offers an all-in-one solution for turning, milling, grinding, automation and Industry 4.0 technologies. Also has a robust manufacturing ecosystem.

Ace Micromatic has opened markets in different industries with advanced CNC machines and smart production systems, with diverse brand portfolios aimed at customized solutions for any machining needs at high precision.

Backed by decades of engineering expertise, the group continues to drive innovation and operational excellence in the global arena.

Business Scope:

• CNC Turning, Milling, and Machining Centers.

• Precision Grinding Machines.

• Special Purpose Machines and Automation Solutions.

• Additive Manufacturing and Laser Cutting Systems.

• IIoT, Machine Monitoring, and Industry 4.0 Solutions.

Recommended Reason:

Ace Micromatic is most suited to a manufacturer looking for an all-around, reliable, and technology-backed machining ecosystem under one roof. In addition, owing to their worldwide presence and relatively high installation base, Ace Micromatic is capable of providing services for a long time and expanding payback periods in a very consistent manner.

Type of Business: Manufacturers of CNC machinery with advanced manufacturing technology solutions.

Year Established: 1961

Manufacturer Introduction:

Established in 1961, BFW India has managed to carve a niche for itself, with over 60 years of experience in CNC machine tool manufacturing and advanced production technologies.

The company is headquartered in India, with modern manufacturing facilities and technology centers, and has an international business reach.

BFW focuses on high-precision machining systems, smart manufacturing, automation, and production solutions powered by Industry 4.0.

Its CNC machines and manufacturing technologies find application in the aerospace, automotive, medical, electronics, agriculture, and defense industries.

Business Scope:

• Vertical machining centers. (VMC)

• Horizontal machining centers. (HMC)

• Vertical and horizontal turning centers.

• 5-axis turn-mill machines.

• Special-purpose machines and smart manufacturing solutions.

Recommended Reason:

BFW would be a wise choice for manufacturers in search of technologically advanced CNC machines with strong innovation and specific industrial solutions to suit their requirements. In addition, the company also offers a strong after-sales support system and localized service across India.

Type of Business: Manufacturer of precision CNC machine tools and automation solutions.

Year Established: 2003

Manufacturer Introduction:

The company, Macpower CNC Machines Ltd., was founded in 2003 in Rajkot, India.

The leading CNC machine manufacturer is active in the field of precision vertical machining centers, horizontal machining centers, turning centers, and multi-tasking CNC solutions.

With experience of over two decades, Macpower has installed 2000 machines in the aerospace, defense, automotive, and general engineering industries, thus offering reliable and innovative manufacturing solutions.

The company runs a modern production facility and integrated R&D, with ISO 9001 quality systems in place so that manufacturing solutions can be delivered to clients with high performance, accuracy, and satisfaction.

Business Scope:

• CNC vertical machining centers (VMC).

• CNC horizontal machining centers (HMC).

• CNC turning centers and multi-tasking machines.

• Robotic automation and custom CNC solutions.

Recommended Reason:

Macpower CNC would be suitable for manufacturers needing reliable, precision-driven CNC machines with cutting-edge automation, great after-sales service, and a proven track record in various industries.

Type of Business: A manufacturer of CNC machining centers and customizable automation solutions.

Year Established: 2003

Manufacturer Introduction:

Yangsen CNC is an internationally operating manufacturer of CNC machines, with over 20 years of expertise in precision machine development and manufacturing.

The company evolved from being a local supplier into a farseeing CNC international brand for OEMs', distributors', and industrial manufacturers' needs.

The company runs a state-of-the-art manufacturing facility of over 100,000㎡square feet, supported by more than 700 trained operators, with an annual capacity of above 5,000 CNC machines.

Yangsen gives importance to machine rigidity, thermal control, and long-term stability of the machines for reliable performance under continuous industrial workloads.

The company is ISO9001 certified, it keeps strict production controls and has an extensive multi-layer quality inspection system.

Business Scope:

• CNC Vertical Machining Centers (VMC)

• CNC Horizontal Machining Centers (HMC)

• CNC Gantry & Double-Column Machining Centers

• Customized automation and turnkey CNC production solutions

Recommended Reason:

It is this perfect blend of performance, durability, and affordability that provides Yangsen CNC an upper hand. While these machines would typically sell for 50-70% of the prices of competing machines from Japan and Taiwan, they achieve 95-120% of similar machining capabilities. Thus, for both manufacturers and distributors, they represent excellent value contracts at the expense of acceptable industrial performances.

Type of Business: Manufacturer of CNC Turning Machines, CNC Machining Centers, and customized industrial automation solutions.

Year Established: 1992

Manufacturer Introduction:

Jaewoo Machines Pvt. Ltd. is one of India's most established as well as fastest developing CNC machine manufacturers. It has more than 30 years of experience in precision machine tool design and production.

Jaewoo has now become a recognized national brand as a consistent Top 10 CNC machine tool company in India, boasting a state-of-the-art manufacturing facility of 250,000 sq. ft.

This is complemented by a skilled workforce of more than 200 engineers, technocrats, and production specialists with an annual production capacity of over 2,000 CNC Turning Machines and Vertical Machining Centers.

Designed for high rigidity, precision, and reliability with a long service life, Jaewoo's machines are ideal for mass production as well as highly accurate industrial uses.

Business Scope:

• General CNC Turning Machines. (Standard & Special Purpose)

• CNC Vertical Machining Centers. (VMC)

• CNC Horizontal Machining Center. (HMC)

• Customized CNC Machines for production lines.

• Industry 4.0-ready CNC solutions.

• Automation-integrated machining systems.

Recommended Reason:

Jaewoo Machines Pvt. Ltd. is definitely the choice for manufacturers in their search for worldwide-scope CNC machines manufactured in India. With more than three decades of experience, strong R&D capabilities, massive production capacity, and competitive pricing, Jaewoo offers a perfect mix of precision, long life, and return on investment (ROI).

Type of Business: Manufacturer, Exporter, Supplier, Trader & Service Provider of CNC Machines and Precision Engineering Solutions.

Year Established: 1998

Manufacturer Introduction:

Tirupati CNC was founded in 1998 and was established by Shree Praveenbhai Shivabhai Sojitra, and is now under the guidance of Mr. Jignesh & Dhaval Bhai Sojitra.

Tirupati CNC Products has earned goodwill in the industry, maintaining quality manufacturing and customer-oriented engineering alongside continued innovation, based on decades of experience and a modern manufacturing facility.

Tirupati CNC Products is reputed in India and also among the users of precision manufacturing CNC machine-their high-performance, robust, and cost-effective solutions for production.

The company manufactures CNC Lathe Machines, Slant Bed Turning Machines, VMC Drilling Machines, Roll Turning Lathes, and Heavy-Duty CNC solutions.

Business Scope:

• Manufacturing of CNC Lathe Machines.

• CNC Turning Centers & Heavy-Duty CNC Machines.

• CNC Roll Turning & Oil Country Pipe Threading Machines.

• VMC Drilling Machine.

• Customized CNC Solutions as per Client Requirements.

• Installation, Mechanical Services & after-sales support.

Recommended Reason:

For most of its decades of experience in manufacturing machines, Tirupati CNC Products is recommended, with strong machine designs and an approach inclined towards customers. What comes to crown the recommendation is the ability to customize CNC solutions right from the advanced infrastructure, competent manpower, and reliable after-sales service.

Type of Business: Manufacturer & Supplier of Precision Sheet Metal Components, Industrial Machines, Dies, Gauges, and Special Purpose Machines.

Year Established: 1983

Manufacturer Introduction:

J.S. Engineering Works was established in the year 1983, recognized for its excellence in high-precision engineered components and industrial machinery.

The main activity of the company is precision and critical sheet metal components, fine blanked components, dies, inspection and receiving gauges, and special-purpose machines.

Supported by a modern CNC machine setup, advanced tooling, and a seasoned technical team, J.S. Engineering Works delivers stringent industry and automotive standards meeting products.

In addition, certifications like ISO 9001:2000 and IATF 16949:2016 complement the credibility of the company in the automobile and engineering sectors.

Business Scope:

• Precision Sheet Metal Components Manufacturing

• Power Presses & Teeth Cutting Machines

• High-Speed Special Purpose Machines

• ABB Robotic Welding Systems

• CNC & VMC Machining Support

Recommended Reason:

With four decades of manufacturing and guidance, strict quality and precision, J.S. Engineering Works comes across as an ultimate value addition in terms of the timely delivery schedule and makes for a reliable partner for the auto and industrial component manufacturing.

Type of Business: Industrial machinery trader and CNC machine supplier.

Year Established: 2011

Manufacturer Introduction:

Shree Yantra Solutions is a company that came into operation in 2011 and is well known for specializing in CNC.

It offers an extensive range of lathe machines, CNC lathe machines, gantry machines, milling machines, and digital readout (DRO) systems for engineering applications.

The company primarily deals in the most advanced industrial machinery and accessories like power chucks, CNC controllers, linear scales, surface grinding machines, and precision tooling solutions that perform functionally well and possess durability.

Shree Yantra Solutions, in quick turn-arounds, provides flow from other major sourcing networks, which coincidentally develops technical expertise in factories, production industries, workshops, professors, and students.

Business Scope:

• CNC Lathe Machines and CNC Turning Centers

• Digital Readout Systems (Sino, Delos, DRO Displays)

• Linear Scales, Ball Screws & Rotary Encoders

• CNC Controllers, Servo Motors & MPG Hand Wheels

• Surface Grinding Machines & Wire Cut EDM Machines

Recommended Reason:

Wide product portfolio, strong distribution network and customer-oriented business approach make Shree Yantra Solutions recommendable. The ability to provide cost-effective solutions for reliable machinery with flexible payment options, coupled with timely deliver,y makes it preferred by many small and medium manufacturers.

Type of Business: Manufacturer and supplier of CNC machine tools and metalworking equipment.

Year Established: 2011

Manufacturer Introduction:

Electronica HiTech Machine Tools was established in 2011 and is one of the world's premier manufacturing solution providers with a focus on advanced CNC machine tools and sheet-metal manufacturing solutions.

The company has built on over four decades of group-level experience related to sourcing, manufacturing, and application engineering in machine tools.

Electronica HiTech is involved in manufacturing CNC Turning Centers, EDM, and CNC Wire EDM Machines, while further importing world-class machines from globally recognized manufacturers.

A strong ethical foundation, combined with a customer-first philosophy, evolved the company into delivering end-to-end manufacturing solutions, from machine selection application study to installation, training, spare parts support, and after-sales service.

Business Scope:

• CNC Turning Centers.

• CNC Wire EDM & EDM Machines.

• Double Column Machining Centers & VTLs

• CNC Fiber Laser Cutting Machines

• Hose Crimping & Cut-to-Length Line Machines

Recommended Reason:

Electronica HiTech Machine Tools Pvt. Ltd. is an advisable enterprise based on solutions, global sourcing strength, and a robust after-sales support network across India. Backed by 40+ years of industry legacy and advanced manufacturing capabilities, CRM-driven customer service ensures high machine uptime, precision output, and long-term value for customers.

Type of Business: Manufacturer & Supplier of CNC Machines.

Year Established: 2021

Manufacturer Introduction:

It was in 2021 that OM CNC Automation came into being, owing to the demands of rising industries for CNC-based machine setups in demand.

The reputation the company has made in a very short span in the market is that of a fine manufacturer and supplier of CNC machines with performance-oriented precision, durability, and consistency.

Assured by ethical business practices and customer-centric policies, OM CNC Automation specializes in the production of technologically advanced machines installed with premium quality raw materials.

Equipped with the latest production machinery and CNC technology, the modern manufacturing facility of Rajkot, Gujarat, is capable of providing world-class market-customized as well as cost-effective solutions to any industrial client.

Business Scope:

• Flat Bed CNC Machine

• CNC Turning Machine

• CNC Drilling Machine (2Axis)

• VMC Drill Machine (3Axis)

• CNC Roll Turning Lathe Machine

• CNC Lathe Machine

Recommended Reason:

OM CNC Automation is rated among the best for its value-based CNC solutions, stringent quality standards, and customer-oriented approach. It is a trustworthy partner to the manufacturing and engineering industries, promising productivity and precision in the long run since it manufactures customized, durable and technologically advanced CNC machines.

What is a VMC machine?

Vertical machining centers are CNC machine tools in which the spindle arrangement is vertical, allowing accurate milling operations, such as drilling, tapping, or contouring, to take place. Its application is in complex components that demand accuracy above all else and repeatability.

Why do VMCs matter to the Indian industry?

VMC is one of the essential things for the Indian industry because they provide a highly precise manufacturing process without being very expensive. They must be very much depended on by the industries of automotive, aerospace, electronics, mold making, and any other assembly units for holding tolerances and cycle times shorter and much more consistent.

What points should be given consideration while selecting a VMC manufacturer?

There are some key factors to consider, such as Machine Rigidity, Spindle performance, Thermal stability, Reliability of the CNC Controller, and Integration with given parameters for automation in any case.

Can Indian VMCs match global standards?

Of Course, numerous VMC manufacturers in India engineer ISO-certified machines that are globally accepted constructs in terms of performance and quality. Such machines are furnished with state-of-the-art control systems, precision guideways, and rugged castings equivalent to international brands.

How does Automation benefit VMC Operation?

Productivity gets boosted as it reduces manual intervention, lowers errors, and enables continuous multi-shift operations. Moreover, using automated tool changers, pallet systems, and robotic integration would increase machine utilization and consistency. This will give lower operating costs, improved quality of output, and shorter return on investment.

Do Indian VMCs fit small- to medium-sized manufacturers?

Yes, Indian VMCs are well-suited for small and medium manufacturers: The price, reliability, and scalability mixture is quite good. Modular configurations offered by many manufacturers allow for gradual upgrades toward general automation that makes Indian VMC among the possible choices for growing businesses without compromising precision or durability.

India’s VMC manufacturing sector now delivers rigid, precise, and automation-ready vertical machining centers for industries such as automotive, aerospace, mold making, and general engineering. When selecting a VMC, factors like reliability, automation compatibility, and service support matter as much as specifications.

For manufacturers seeking a cost-effective, high-performance VMC, exploring CNC Yangsen’s vertical machining centers is an effective way to achieve higher productivity and long-term stability.