On a voyage into CNC machines, a crucial part known as the CNC Spindle Motor emerges. This write-up brings to light how Spindle Motors stand apart from the X, Y, Z Servomotor.

The aim is to make clear the essence of Spindle Motors in CNC machines, dive into their variants, and highlight their unique features. Moving forward, expect a complete understanding of this crucial part.

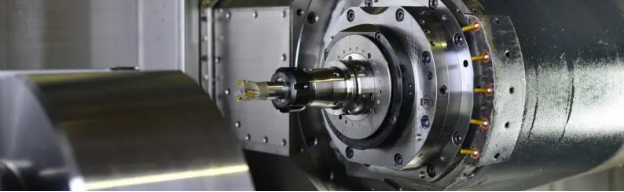

A CNC Spindle Motor spins the cutter in CNC machines. High precision results from spindle motors. They are made for durability. Power ranges from 1 to 40 horsepower. Speed capabilities vary between 6,000 and 24,000 RPM.

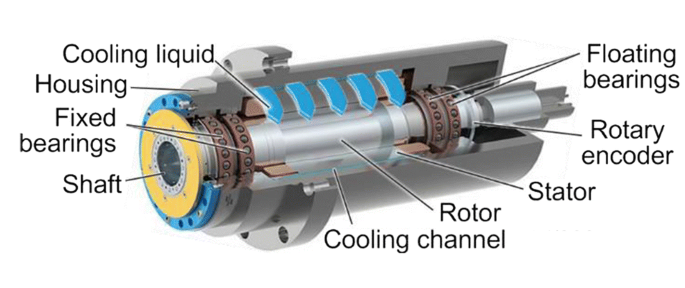

The motor housing holds parts together. Power source, bearings, and shaft are crucial parts. Spindle motors offer low heat production, quiet operation, and great efficiency. Every part contributes to the CNC Spindle Motor's superb performance.

FANUC, a top brand, is from Japan. They manufacture high-quality spindle motors. FANUC motors stand out for their precision. Speed and power are their key strengths.

A wide range of power options exists, from 2.5 to 22 kilowatts. Speeds reach up to 15,000 RPM. Motor performance excels in FANUC products. Such details underline FANUC's position in the spindle motor market.

● Air Cooled: Air-cooled spindle motors use fans. They reduce heat during operation. Air-cooled motors are simpler and less expensive. But they may not manage high heat loads.

●Water Cooled: Water-cooled spindles use liquid coolant. They can handle more heat. However, they need more maintenance. Yet, they are quieter and longer-lasting.

●Electric: Electric spindle motors are highly efficient. They offer smooth operation. Electric spindles are versatile, used in many applications.

●High-Speed: High-speed spindle motors are for rapid work. They reach speeds up to 60,000 RPM. Precision is excellent, but cooling is crucial.

●Manual: Manual spindle motors need human control. They are for simpler tasks.

√High-speed spindles reach 60,000 RPM. They are used for detailed work.

√Medium-speed spindles operate between 12,000 to 24,000 RPM. They offer a good balance of speed and power.

√ Low-speed spindles work under 12,000 RPM. They are for heavy-duty tasks.

√Spindle speed can affect surface finish. Higher speeds offer smoother finishes.

√Spindle speed can influence tool life. Appropriate speeds reduce tool wear.

√Optimal spindle speed depends on the material. Harder materials need slower speeds.

•Power Source: Your 110v spindle motor relies on a common electrical outlet. For your 300w spindle, a power supply unit provides needed energy. Both serve to keep CNC machines in action.

•Performance Metrics: The 110v spindle motor exhibits a higher rotation speed. In contrast, a 300w spindle motor's performance depends more on the power supply. Balance these factors with precision needs.

•Application Suitability: For small tasks, a 110v spindle motor suffices. Meanwhile, your 300w spindle motor manages heavier duty work with ease.

•Efficiency Factors: The 110v spindle motor tends to consume more power. On the other hand, the 300w spindle motor boasts energy-saving benefits.

•Safety Concerns: Both spindle motors have safety features. However, with a 110v spindle motor, surge protection is crucial. The 300w spindle motor's power supply should feature short circuit protection.

Brushless spindle motors are preferred for their smooth operation. Unlike brushed motors, brushless motors eliminate the need for brushes. By doing so, brushless spindle motors reduce friction and offer a quiet run.

This, in turn, leads to extended motor lifespan. These motors also provide higher torque-to-weight ratios, essential in CNC machinery. The robust construction of brushless spindle motors promotes durability.

For your CNC spindle motor, this means less maintenance and more uptime. Brushless motors adjust speed to suit application demands, enhancing machining efficiency. They offer excellent heat dissipation, ensuring the CNC machine's longevity.

√Jewelry Making: In crafting intricate jewelry designs, the precision offered by a 500w spindle motor is irreplaceable.

√Component Manufacturing: In the fabrication of small mechanical and auto parts, a 500w spindle motor guarantees high accuracy.

√Woodworking: Carving out detailed patterns in wood requires the power and precision of a 500w spindle motor.

√Prototype Development: The 500w spindle motor aids in creating detailed and accurate prototypes.

√Educational Uses: In school labs, the 500w spindle motor provides safe and efficient operation for learning CNC techniques.

•Lathe Spindle Motor: Designed for turning applications, a lathe spindle motor ensures accurate cylindrical cuts.

•Mill Spindle Motor: For cnc milling machine operations involving material removal, a mill spindle motor provides the required torque.

•Router Spindle Motor: Ideal for cutting designs onto flat surfaces, router spindle motors ensure precision and speed.

•Specific Design: Each spindle motor type incorporates unique design features to suit respective applications.

•Component Compatibility: Lathe, mill, and router spindle motors require specific machine components for efficient functioning.

•Maintenance Protocols: Maintenance procedures vary between lathe, mill, and router spindle motors, reflecting design differences.

|

Criteria |

110v Spindle Motor |

300w Spindle Motor |

Brushless Spindle Motor |

500w Spindle Motor |

Lathe Spindle Motor |

Mill Spindle Motor |

Router Spindle Motor |

|

Power Source |

Electrical Outlet |

Power Supply Unit |

Varies |

Varies |

Varies |

Varies |

Varies |

|

Performance Metrics |

High Rotation Speed |

Depends on Power Supply |

Smooth Operation |

High Accuracy |

Cylindrical Cuts |

Material Removal |

Precision & Speed |

|

Application Suitability |

Small Tasks |

Heavy Duty Work |

CNC Machinery |

Jewelry, Components, Woodworking, Prototypes, Education |

Turning Applications |

Material Removal |

Designs on Flat Surfaces |

|

Efficiency Factors |

High Power Consumption |

Energy-saving |

High Torque-to-weight Ratio |

Varies |

Varies |

Varies |

Varies |

|

Safety Concerns |

Surge Protection Needed |

Short Circuit Protection Needed |

Varies |

Varies |

Varies |

Varies |

Varies |

|

Design Specifics |

Varies |

Varies |

No Brushes, Heat Dissipation |

Varies |

For Turning |

For Material Removal |

For Flat Surface Designs |

|

Component Compatibility |

Varies |

Varies |

Varies |

Varies |

Specific Components |

Specific Components |

Specific Components |

|

Maintenance Protocols |

Varies |

Varies |

Less Maintenance |

Varies |

Unique Protocol |

Unique Protocol |

Unique Protocol |

Table on Variations in Spindle Motors! Learn more click here to contact us

To cut swiftly, spindle motors run fast. A CNC Spindle Motor can reach 40,000 RPM. RPM means Revolutions Per Minute. That's fast! When motors run fast, work gets done quicker.

No one likes shaky hands. Spindle motors don’t either. They’re built strong. That makes them steady. When steady, they make nice, clean cuts. The result is high-quality products.

Spindle motors can be strong or stronger! Horsepower, or HP, tells how strong. Some have 1 HP. Others have 20 HP. More HP helps cut tougher materials.

Motors can get hot. Too hot is bad. Coolant helps keep them cool. Cool spindle motors work better and last longer.

Accuracy means no mistakes. A CNC machine with a spindle motor makes tiny errors. Errors as small as 0.0001 inches. That’s thinner than paper!

Change is good. Spindle motors can change tools. Different tools mean different cuts. This makes CNC machines very useful.

Some jobs are big and tough. Spindle motors can handle them. They support large materials. They’re strong and work for a long time.

Servomotors are smart motors. They are like brains for machines. They know where to move and how fast. They use electricity. In a CNC machine, they help spindle motors.

A servomotor can turn very fast or very slow. It can move in tiny steps. It’s great for precision.

Imagine a box. The box has three sides. Let’s call them X, Y, and Z. In a CNC machine, servomotors move along these sides. The X motor moves left and right. The Y motor moves front and back. The Z motor moves up and down. They work together to guide the spindle motor.

Spindle motors have one job: spin fast. Servomotors have many speeds. They can spin fast or slow. They are better at speed control. Spindle motors focus on power.

Spindle motors hold and turn cutters. Servomotors move things. In CNC machines, servomotors move the spindle motor. Different jobs, but both important.

Servomotors are complex. They can make tiny movements. Spindle motors are simpler. They focus on strong, fast spinning. Servomotors are better for precise jobs.

Spindle motors need more power. They use more electricity. Servomotors use less. Less power means lower bills.

Torque is twisting power. Spindle motors have high torque at high speeds. Servomotors have high torque even at low speeds.

Spindle motors need coolant. They get hot. Servomotors stay cooler. They need less care.

Spindle motors are best for cutting. Servomotors have many uses. They’re in robots, cameras, and more. They’re more flexible.

Both motors can last a long time. But, spindle motors can wear out faster. They work harder and get hotter. Servomotors usually last longer.

•High voltage means strong power. CNC Spindle Motors need this to cut hard materials. More voltage helps in smooth cutting.

•Voltage stability is crucial. Motors perform better when power does not change. Steady voltage assures high precision.

•Using low voltage saves energy. For soft materials, less voltage is enough. Thus, saving costs in long-term operations.

•Voltage spikes damage motors. Sudden high voltage can hurt motor parts. Good voltage regulators keep motors safe.

•Motors with high voltage need strong cables. Thick wires carry power without heating up. Good wires add life to motors.

•Voltage effects torque. More voltage makes high torque. High torque helps in fast and accurate cutting.

•Correct voltage maintains motor temperature. Too high voltage makes motors hot. Hot motors wear out fast.

•Motors lose power at low voltage. Less power means slow cutting. Slow cutting can ruin work and waste time.

CNC machines cut, shape, and grind materials. High RPM means fast spinning. Faster spins make cleaner cuts. For metals, 10,000 to 30,000 RPM is common.

High RPM helps motors tackle hard materials. Thus, ensuring excellent output quality. But, high RPM makes heat. So, cooling systems are essential. Good RPM keeps motor performance steady. Steady motors create great products.

•Belt-driven spindle motors often run below 12,000 RPM. For rough materials, slow RPM is fine. Low RPM saves motor life.

•Electric spindle motors have RPMs above 30,000. Fast spins need strong bearings. These motors do precision cutting.

•Direct-drive spindle motors run between 5,000 and 10,000 RPM. No gears or belts here. Thus, maintenance is less.

•High-speed spindle motors go up to 60,000 RPM. Super fast! Perfect for detailed work. Great for medical industry and jewelry tasks.

•Liquid-cooled spindle motors have 24,000 RPM. The liquid keeps motors cool. Cool motors work for long hours.

Spindle motors and servomotors both serve vital roles. However, spindle motors focus on cutting. Servomotors move machine parts. Spindle motors reach up to 60,000 RPM.

Servomotors go between 2,000 and 5,000 RPM. High RPM in spindle motors gives clean cuts. Servomotors need less RPM. Precision movement is the aim for servomotors. So, RPM varies based on tasks.

CNC motors get hot during work. Hot motors may fail. Cooling keeps motors safe. Cooling systems also prolong motor life. Air and liquid are common coolants.

The coolant flows around the motor. It takes away the heat. Thus, motors stay cool and work well.

Air-cooled spindle motors use fans. Fans blow air to cool motors. Air-cooling is simple and low-cost. But, for heavy tasks, air is not enough. Water-cooled spindle motors use water.

Water takes away more heat than air. Water-cooling is great for long, hard jobs. But, water-cooling systems cost more.

Servomotors also need cooling. Some servomotors use air-cooling. Fans help here too. Others use liquid-cooling. In liquid-cooling, coolant flows through motor tubes.

It takes away heat. Liquid-cooling is best for high power servomotors. Cool servomotors work well and last long.

CNC motors, unique to their home regions, abound worldwide. In the US, high speed is a common feature. Expect around 24000 RPM. Europe prefers powerful ones.

German-made motors reach 18.5 kW capacity. China boasts of versatile CNC motors. Their motors operate within a 12000-24000 RPM range.

CNC spindle motors serve critical roles in India, UK, South Africa. India’s industries prioritize affordability. A standard 1.5 kW spindle motor costs around $200. The UK leans towards durability. Their favorite brand, Jäger, promises 60,000 hours of service.

In South Africa, demand for high-precision motors is high. Exact machining is a common requirement.

Enhancing the CNC 3018 with a 500w spindle motor improves performance. You'll enjoy better torque. Expect around 0.46 Nm. Speed improves as well. 500w motors can hit 12000 RPM. Cutting ability sees a boost too. You can cut harder materials.

√Benefit: Enhanced performance. A 500w spindle motor cuts at faster speeds.

√Drawback: Higher energy use. A powerful motor means more electricity.

√Benefit: Better material handling. Your CNC machine can tackle harder substances.

√Drawback: More maintenance. Powerful motors need regular upkeep.

Regular motor checks keep your CNC machine running smoothly. A monthly inspection is ideal. Always check the temperature. Overheating is a common problem. Monitor for unusual sounds too. Grinding noises often hint at bearing issues.

•Overheating: This could damage your motor. Regular cooling is crucial.

•Noise: Unusual sounds often mean mechanical trouble. Bearings might need replacement.

•Speed inconsistency: If your motor isn't maintaining its speed, calibration may be needed.

•Power problems: A failing motor might not start at all. Check your electrical connections.

· Check temperature: Make sure your motor isn't overheating.

· Listen for noise: Unusual sounds can indicate mechanical issues.

· Monitor speed: Ensure the motor maintains a consistent RPM.

· Inspect power: Make sure your motor starts without issue.

· Regular maintenance: Keep your motor clean and lubricated for smooth operation.

Having journeyed through the realm of Spindle Motors, their importance in CNC machines is now clear. Distinct from Servomotors, they have a unique role and variety.

From cooling methods to voltage needs, and RPM, they are a pivotal part of CNC operations. Continue the quest for CNC knowledge and explore more at CNC YANGSEN, where the world of CNC is at your fingertips.