During the last few years, the medical industry has witnessed innovative development. It is driven by the incorporation of leading-edge advanced technologies.

Among these, Computer Numerical Control also known as CNC machining has emerged as a benchmark technology. It helps in providing reliability, exceptional accuracy, and customized production for medical devices and tools.

Such machinery also changes working abilities. With its truthful outputs, medical devices perform better than before. Moreover, CNC machining in the medical industry has paved the way for reliable medical facilities. This inventive idea enriches healthcare services and makes them effortlessly accessible for all.

Through this article, we will explore how CNC machining for medical industry is reforming the healthcare sector. We will also highlight the roles, benefits, applications, innovation, and future of CNC machinery.

It is important to recognize the meaning and purpose of CNC machining before we move to its medical implementations. Computer numeric control, also recognized as CNC machining, is a manufacturing procedure that operates on computerized panels to handle the machinery.

It includes crushers, lathes, mills, and routers. The machinery helps in producing complex parts with elevated accuracy by considering the pre-programmed designs.

When it comes to the medical industry, which requires high accuracy, CNC machining is considered a gold standard for producing devices. Furthermore, it helps in crafting components that meet severe regulatory requirements. This high-demand accuracy ensures the safety of patients and their well-being.

CNC machining, with its accurate results and reliability factor at a higher level every time, makes it desirable for producing complex medical devices, implants, and diagnostic tools.

For a more and better familiarity, let’s discover the role of CNC machining in the medical industry.

CNC machining for medical industry plays an essential role in the advancement and manufacturing of medical instruments. This innovative idea is helping save lives and improving diagnostics. Moreover, it increases the quality of health care.

Here, we have some of the key applications of CNC machining in the medical field.

In recent times, CNC machining has been broadly used to produce surgical instruments. The most used tools include blades, clamps, and forceps. Such tools need perfect accuracy to ensure that the surgeons can perform delicate procedures efficiently. These machines create ease for working staff and assist them in producing accurate results.

CNC machines can create medical instruments with smooth controls and desired specifications. This procedure is crucial in preventing tissue that may get damaged during the surgery process. Also, this advanced technology improves medical facilities without much hassle.

With the increase in population, more medical facilities are required at all levels. Advancements in technology and innovative tools are the demanding factors in the medical industry. For such reasons, medical devices like ventilators, insulin pumps, and pacemakers need complicated and accurate components.

In this regard, CNC machining makes sure that these tools meet the high standards of healthcare. Furthermore, it ensures the reliability and durability that are needed for the life-sustaining types of equipment for patients.

As we know all patients are distinctive and require specific treatment. Therefore, CNC machining offers the customization of implants and prosthetics.

This method supports tailoring to an individual’s anatomy. Additionally, with CNC machining every patient is treated at the individual level with specific treatment and process.

Whether it is dental implantation or hip replacements, CNC machining confirms these components fit accordingly and function properly. Moreover, such machinery can work with biocompatible materials. It includes stainless material and titanium further highlighting its implications in the medical industry.

With the advancement in technology, the medical industry is also continuously developing. For this, the credit goes to the experienced researchers and competent engineers. As they are helping to introduce the innovative devices and technologies for medical industry.

The Advanced CNC machining facilitates the rapid prototyping. It enables the fast production of accurate prototypes. This process helps in testing and modification methods. This facility enhances the time-to-market for revolutionary medical solutions in this era.

Now, before jumping to the producing technicalities, let’s discuss the benefits of CNC machining for medical industry.

The medical industry is enjoying numerous advantages by adopting the CNC machining. Let’s discover why it has become essential for the healthcare industry.

The CNC machines are produced with a wide range of materials. These materials include plastics, ceramic ware, and metals. This versatility of material is considered critical in the medical industry. This is because different medical instruments need specific materials. Every tool has its specifications and works differently.

Such as, polymers are used for disposing the medical instruments, while titanium is ideal for the implanting process due to its biocompatibility factor. This flexibility of the material makes CNC machining an ideal revolutionary element for the medical industry.

Customization is a key component of CNC machining for medical industry. From producing a single custom implant to manufacturing thousands of surgical devices, CNC machining never fails to adapt to the requirements. It works according to the given instructions based on personalized guidelines.

The customization at the individual level ensures that manufacturers can fulfill the varied demands of the medical sector professionally. Additionally, it boosts the working capacity in the medical field.

As we know in the medical field, a minor mistake can cause unwanted consequences. Being professionals, no one can take risks for their patients.

Healthcare facilities and proper treatment are the primary concern for all. For this reason, the CNC machining guarantees that the components are created with tolerances as tight as a few microns. It also ensures the accuracy of results for all medical treatments through CNC machining.

Life-saving devices such as surgical tools and implants require this level of precision. Because its accuracy directly affects the patient’s outcomes for treatment. These innovative tools enhance the satisfaction level for both patients and professional medical staff.

A high level of speed and effective outcomes is the desired feature of any machinery. Besides, time is considered of the essence in the medical field.

During emergencies, prompt replies and treatments are all that the professionals are looking for. For this, the CNC machining allows quick production without compromising on the quality. Moreover, it ensures that the needed medical instruments and tools are delivered promptly where required.

Like other professional fields, healthcare also needs to follow some regulatory compliance. In this regard, medical instruments must observe the strict principles proposed by organizations like the ISO and FDA.

These organizations support maintaining high standards for the healthcare sector. Also, it promotes better medical facilities at all levels.

The CNC machining follows all the regulatory guidelines at all stages. They ensure consistency in high quality. Besides, they guarantee the traceability factor throughout the producing method.

After benefits, we need to know about the material used for CNC machining for the medical industry. So, let’s explore!

The selection of materials for manufacturing the medical tools is a critical aspect. CNC machining uses different materials for the different devices. Furthermore, all materials are selected for their specific properties and implementations.

Further down are the most commonly used materials for CNC machining for medical industry:

Another desirable material for CNC machining is the stainless brace. This material is extensively used for surgical tools and implants. Its high durability, ease of purification, and corrosion resistance make it desirable to professionals.

Furthermore, stainless material-based CNC machining makes sure that its components meet the strict quality standards of the healthcare sector.

Titanium is a renowned material used for CNC machining. It is famous for its lightweight, biocompatibility, and strength. The titanium material is highly suitable for surgical instruments and implants.

Titanium-based CNC machining handles accuracy better than others. Also, it ensures reliable performance in medical practices.

Due to the stiffness and wearing resistance, ceramic materials are mostly used by dentists for dental implants. Besides, this material is also used for the bone replacement process. CNC machining ensures the accuracy of the shape needed for the required treatment.

There are many tools, that use plastic material for medical instruments. Due to the high demand, CNC machining starts manufacturing complicated plastic parts with high quality and precision. It helps in providing better medical facilities at an economical level for all needed people.

With the advancement in material, some innovations also take place in CNC machining. We are going to discuss a few of them below.

The innovation in CNC machining equipment is further empowering its role in the medical industry. Some of the prominent innovations are as follows.

Micromachining helps in producing minor and more detailed medical components for better and more accurate results. For this, CNC micromachining is used to generate small parts where needed. It includes hearing aids and slightly aggressive surgical tools for custom needs.

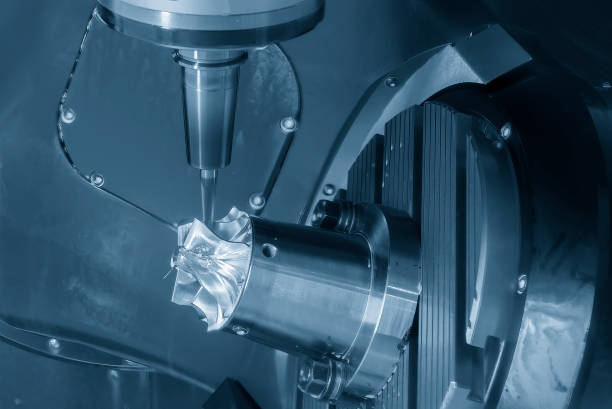

During past times, traditionally working CNC machines typically function on three basic axes which are X, Y, and Z. However, with advancements in technology, 5-axis CNC machining gives higher flexibility. It also enhances the ability to generate more complicated geometries. This proves particularly helpful for creating complicated medical devices.

Artificial intelligence refers to rationalization in CNC machining methods. This advancement helps in enhancing the efficiency and decreasing the faults. For example, AI-generated quality control systems can perceive faults promptly and guarantee reliable output.

Besides all the innovations, still there are some challenges that CNC machining is facing in the medical industry. A few of them are as follows.

However, CNC machining is providing several benefits but still it is facing some challenges also. Let’s encounter these hurdles and their solutions below.

The plantation of CNC machining systems is an expensive process. It requires high costs for its manufacturing and processing. However, it provides the long-term benefits in return. Like, it helps reduce waste and provides a greater efficiency level.

The CNC machining made of ceramics or titanium is challenging to handle. Its hardness makes its working complicated. On the other hand, advanced CNC machines and technologies have resolved this issue. It empowers accurate machining of all materials.

Following the regulatory guidelines in the medical industry is a critical process. It requires more effort and keen attention to overall treatments and procedures. This makes the process more complicated for professionals. However, connecting with experienced CNC machining suppliers who know the regulations ensures that all instruments meet the essential certifications.

Anyhow, it is important to know what this advancement in CNC machining will do in the future. Let’s explore future expectations in the medical industry.

With the evolution in technology, CNC machining for medical industry is also getting heights in the medical industry. The developing trends including 3D printing are being combined with CNC machining. It helps in creating hybrid solutions when needed for better results. This grouping influences the strengths of both innovative technologies and customized medical tools.

In Addition, the practice of digital twins and the internet of things in CNC machining is contentiously enhancing process monitoring and optimization. It ensures high-level accuracy and efficiency of treatments.

CNC machining for the medical industry is a keystone of advanced healthcare facilities and manufacturing. Its ability to provide accurate results, custom outputs, and scalability has transformed the manufacturing of medical tools, innovative instruments, and implant services. Moreover, CNC machining is facilitating the medical industry and its professionals at the global level.

As the medical industry endures continuous technological advancements, CNC machining will remain at the forefront of its innovative results. It helps in ensuring improved healthcare for patients and their consequences.

Lastly, considering the healthcare suppliers and instrument manufacturers, implementing and installing CNC machining is not just an option for them. Now, it is essential for them in the pursuit of excellence in the medical industry.