Excellent Quality & Competitive Price

Excellent Quality & Competitive Price

Online Technical Support

Online Technical Support

Outstanding CNC Machine Brand

Outstanding CNC Machine Brand

Yangsen Machine Tools are built to the highest standards and we have over 500 employees who are committed to providing the best level of service.

CNC Machine Tools below. Simply get in touch with our team by emailing info@cncyangsen.com or calling us +86-592-6682467 or contact us on Whatsapp/Wechat +86 18359729483

Yes, you can be our distributor in your area for CNC machines business.

Yangsen is an improving, open, fair and win-win cooperation platform, to provide opportunities and possibilities for employees, customers, business partners, and shareholders to realize the wonderful dream.

To be our business partners you can get:

1. Your city or area exclusive protective distributor. Your efforts and achievements can be continuously protected and inherited. We will neither allow our brand to compete viciously in your area, nor will it affect your competitiveness in service and price to end customers.

2. Strongest support by our professional and experienced team of more than 500+ employee and 50% over 10 years’ experience in machine tool and mechanical. (Sales, R&D, Production, QC, Shipment, After-sales service). For more details, please refer to Why Us.

3. Free Online Training. You can learn our CNC machines and maintain in our website. Please refer to Training.

4. Online Clients and enquiry in your local market. We will forward positively your market clients to you for direct contact. Our online marketing team composed by 6 professional and creative young persons, who major in marketing and SEO and SEM for more than 5 years.

5. Professional support on exporting and importing, experienced in shipment processes including handling and customs clearance, duties and taxes.

6. Fast response within 12 hours (usually faster) from our hardworking and professional service team, speak and write frequently in English, French, Spanish, Thailand, Vietnam, Russian and Japanese.

7. Joint CNC Machines exhibition in your local market and work together with you to explore the market, dig deep into customers, and listen to their needs.

All things therefore that you want people to do to you, do thus to them"(Mathew 7.12)

In fact, at the moment we have just opened up our distributor channel and we don't have a very strict distributor policy, so it is real right time to be our CNC machines distributor.

But we still hope that our distributors can serve end customers well. Therefore, we wish as below:

1. You have related experience in machine tool technology, maintenance and sales.

2. You have your own physical CNC machines store or company.

3. You have a certain ability of after-sales maintenance. This way you can help customers resolve their minor issues in a timely manner.

If you do not have the above conditions, it does not matter, as long as you love the machine tool business and agree with our values, we are also very willing to communicate with you and help you become a qualified CNC machines distributor.

So don’t be hesitant to contact us today and start your business.

How to become a distributor of Yangsen CNC Machine?

1. To apply to become a distributor, you need to have legal qualifications and the following conditions:

1. The registered capital (paid in) shall not be less than 2 million USD;

2. The company has a good business reputation and more than 3 years of experience in operation and cooperation;

3. Have a professional service team for CNC machine or mechanical technology, marketing, sales and after-sales maintenance;

4. In the pre-authorized distribution area, there are abundant channel resources;

5. Agree and accept the requirements of Janssen CNC machine tools on contract payment, partner qualifications, etc.

Application process:

Step1: Please download the dealer application form and fill in your company information truthfully.

![]() Distributor Application Form.xlsx

Distributor Application Form.xlsx

Step2: Please send the completed application form as an attachment and send it to us.

Step3: Qualification review, the staff will contact you in time after the review is passed, communicate about joining and sign a cooperation agreement.

Step4: Sign a distribution agreement.

Step5: Place an order for purchase.

Yangsen provides partners with a broad stage to show their talents and opportunities to realize their dreams, to share responsibilities, to create value, to share benefits, to achieve goals and to realize development.

The Yangsen also attaches great importance to internal talent training and partners self-learning, providing regular training on the latest international information, marketing and sales skills, so that partners can achieve continuous learning, self-improvement, and keep pace with the times.

It is true that CNC machine are relatively expensive products, and we understand your concerns on after-sales service very well. Therefore, before each of our CNC machine is shipped, we do a very detailed full inspection.

At the same time, we have Distributors in 5 countries around the world (more and more soon):

1. Malaysia

2. South Korea

3. Brazil

4. Dubai

5. Italy

Once you become our customer, our distributors will undertake the corresponding after-sales maintenance guarantee.

If there is no our distributor in your area, we provide the following terms of after-sales service:

The following conditions are excluded and are not covered by the warranty:

1. Using an improper power source

2. Machine failure caused by improper operation

3. Damage to electrical components caused by live disassembly and assembly of equipment

4. Damage caused by other natural disasters, such as lightning strikes, earthquakes, floods and other natural disasters

2. During the warranty period, the door-to-door service fee and other expenses incurred by the door-to-door service are not included, and the user needs to pay separately, as follows:

1 Labor cost calculated by day 100USD/day

2 transportation expenses round-trip air or train tickets

3. Accommodation fees Local three-star or above standard room fees

Please remit the relevant expenses to our company's account in advance, and our company will issue an invoice for the relevant expenses. Except for the above expenses, other expenses will be borne by the manufacturer.

Main: We will calculate the number of maintenance days and accommodation days according to the corresponding items and negotiate with the user. The expenses incurred beyond the specified time will be borne by our company, including accommodation fees and other expenses

3. Maintenance method during the warranty period:

The customer describes the fault in detail, and sends it to our company's after-sales service department by email, or communicates by telephone, and the after-sales service engineer judges the cause of the fault, and guides the customer to detect and judge on the phone, and guides the customer to remove the faulty parts. Express way to our company's after-sales service department. After receiving the customer's parts, the company's after-sales service department will conduct further testing. If it is confirmed that there is a fault, it will express new parts to the user within 1 working day, and guide the user to install and debug. Our company bears the cost of spare parts.

All express delivery costs incurred in the above process shall be borne by your company. If the customer cannot complete the above work, the manufacturer needs to provide door-to-door service. The charging method is in accordance with Article 2.

4. Maintenance methods outside the warranty period:

Same method as 3

Expenses: The user needs to bear the spare parts. For the specific price, please call the receiving service department. For the express delivery fee, in order to ensure that the correct spare parts are purchased, it is recommended to send back the spare parts for testing. The warranty period for new spare parts is one year, and the service fee (Free of charge), if the user needs to provide door-to-door service, please refer to Article 2 for the charging standard.

5. About installation:

The price of all the machines sold does not include installation and training. Since the machines are debugged before leaving the factory, all users do not need to debug.

On-site installation fee: refer to Article 2 charging standard

6. Regarding training:

Training: Our company provides free online training courses to help customers quickly familiarize themselves with our machine tool products and improve production efficiency.

If you need the on-site training, please make an appointment in advance. For on-site training fees, please refer to Article 2 Fee Standards.

CNC maintenance technology (computer numerical control) is not only the premise to ensure normal operation, but also plays a huge role in promoting the development and improvement of CNC technology, so it has become a specialized subject at present.

Any CNC machines are process control equipment, which requires it to work accurately at every moment of real-time control. Failure and failure of any part will cause the machine to stop, resulting in a production stoppage and machine breakdown.

Therefore, it is very necessary to do the device preventive maintenance with complex principles and precise structures such as the numerical control system. Especially for imported CNC machine tools, most of which cost hundreds of thousands to tens of millions of dollars. In many industries, this equipment is in key jobs.

The following tasks have to be done every day, assuming regular usage hours:

1. Inspect the pressure and level of lubricant. Top up if required. Guaranteed machine lubrication.

2. Check the coolant level; If it is not enough, please add coolant in time. Use a coolant refractometer to ensure the coolant and oil ratio is maintained.

3. Clean out the coolant disposal tray. Check the oil level of the pneumatic triple piece, which is about 2/3 of the height of the entire oil pipe. The water vapor in the pneumatic triple oil filter tank is discharged from the drain switch every day.

4. Check for moisture in pneumatic air. Drain moisture if it is detected.

5. Check the pressure of pneumatic air with the pneumatic pressure gauge. Check the air pressure, loosen the adjustment knob, and adjust the pressure according to the principle of right-handed pressure increase and left-handed decompression, generally set to 5~7KG/CM2. The pressure switch is usually set to 5KG/CM2. When the pressure is lower than 5KG/CM2, the alarm will appear, and the system will display a 'LOW AIR PRESSURE' alarm. After the pressure rises, the alarm message will disappear.

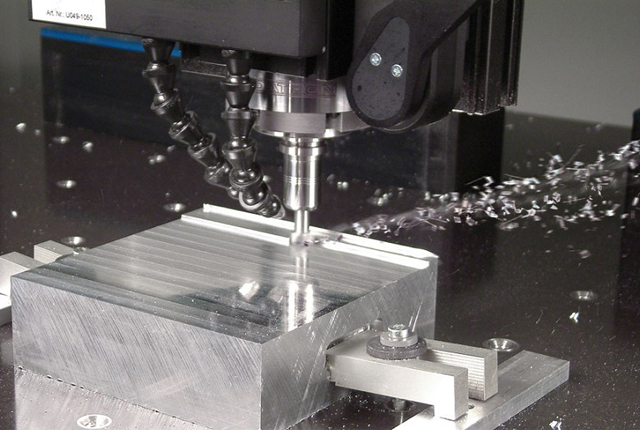

6. Wipe the complete machine with a clean rag. Remove the cutting and oil stains on the worktable, inside the machine tool, and on the three-axis telescopic shield.

7. Check the output of the voltage stabilizer. Ensure it adheres to the required specifications.

8. Check panel cooler temperature.

9. Observe noises, bangs, or any other anomalies in machine operation.

10. Watch out for any overheating signs during machine operation.

11. Check whether the air blowing in the inner taper hole of the spindle is normal, wipe the inner taper hole of the spindle with a clean cotton cloth, and spray light oil.

12. Clean the tool magazine tool arms and tools, especially the tool claws.

13. Clean exposed limit switches and bump blocks.

14. Check whether all signal lights and abnormal warning lights are normal.

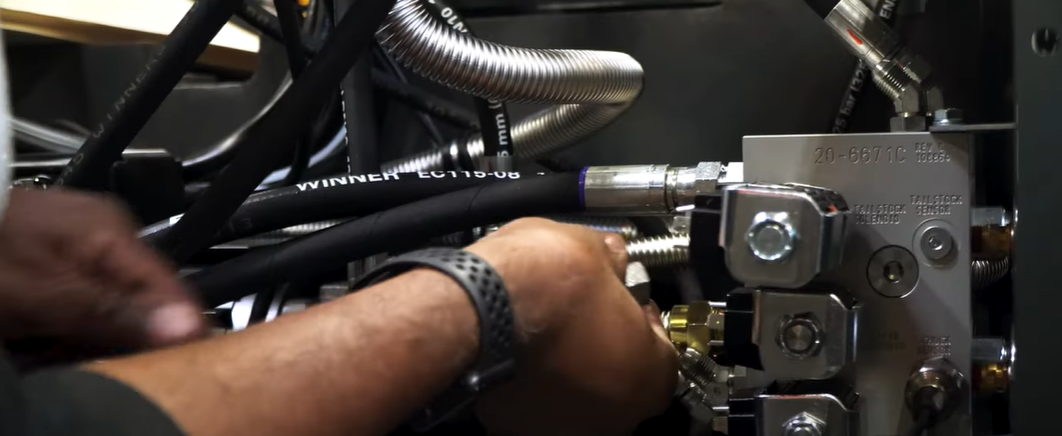

15. Check whether there is leakage in the oil pressure unit pipe.

16. The machine tool should be cleaned after the daily work is completed.

17. Keep the environment around the machine clean and tidy.

The following maintenance tasks have to be done on a weekly basis:

1. Clean the complete machine shop, especially the area surrounding the machine.

2. Check for any evidence of lubricant, oil, or coolant leakage.

3. Check and ensure all cooling fans are working properly. These include spindle motor fans, cooling system fans, hydraulic motor fans, and hydraulic pressure. Clean the air filter screen of the heat exchanger, the filter screen of the cooling unit, and the lubricating oil pump.

4. Perform a visual inspection of machine components. Apply grease or appropriate lubricant to parts that seem dry.

5. Check whether tool heads are held securely in the tool changer and clean or not.

6. Lubricate the v-groove, plungers, slider cap, extractor forks, keys, and springs of the tool changer.

7. Check if all electrical components such as switches and lights are working properly.

8. Check whether the three-axis mechanical origin is offset.

9. Check whether the tool changer arm of the tool magazine or the tool magazine rotates smoothly.

10. If there is an oil cooler, check the oil cooler oil. If it is lower than the scale line, please add oil cooler oil in time.

11. Check the set temperature of the oil cooler, it is recommended to set it between 26-28 degrees.

Maintenance checks that should be done every month include the following:

1. Clean out the chip collector close to the coolant tank.

2. Inspect, remove, and adjust jaws, chucks, and fixtures.

3. Clean or replace air filters as required.

4. Check the condition of tool heads and change them if necessary.

5. Inspect, lubricate, tighten, and adjust chains and conveyors in the machine.

6. Clean various fans of the machine to prevent dust accumulations.

7. Inspect the logs of oil, lubricant, and coolant. Check for any anomalous consumption.

8. Clean radiator grills of dust and debris.

9. Check the lubrication of the X, Y, and Z three-axis track, and the track surface must be well-lubricated.

10. Check and clean limit switches and bumps.

11. Check whether the oil in the oil cup of the knife cylinder is sufficient. If it is insufficient, please add it in time.

12. Check that the signs and warning nameplates on the machine are legible.

CNC machine maintenance checks that need to be done semi-annually:

1. Disassemble the triaxial anti-chip guard, clean the triaxial oil pipe joint, ball lead screw, and triaxial limit switch, and check whether it is normal. Check whether the effect of the hard rail wiper blades of each axis is good.

2. Check whether the servo motor and head of each axis are running normally and whether there is any abnormal sound.

3. Replace the oil of the hydraulic tank and the oil of the deceleration mechanism of the tool magazine.

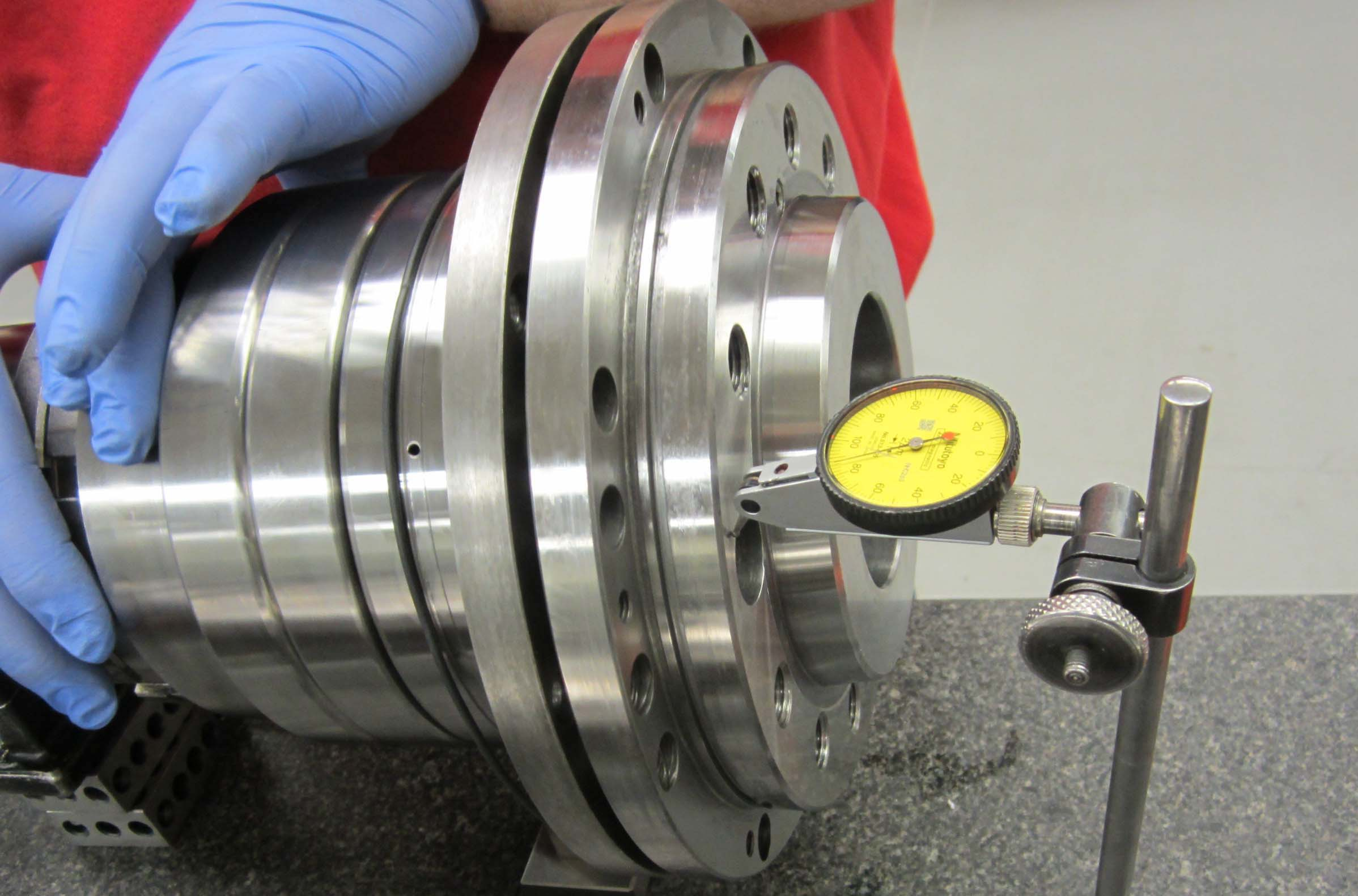

4. Test the clearance of each axis, and adjust the compensation amount if necessary.

5. Clean the dust in the electric box (make sure the machine tool is turned off).

6. Comprehensively check whether all contacts, connectors, sockets, and switches are normal.

7. Check and adjust the mechanical level.

CNC machine maintenance checks that need to be done annually:

1. Check whether all keys are sensitive and normal.

2. Clean the cutting water tank and replace the cutting fluid.

3. Check the vertical accuracy of each axis and decide whether it needs to be adjusted.

4. Remove the coolant cylinder tank for inspection.

5. Clean out the coolant cylinder for debris, inspect for bacteria or fungal growth, and clean the tank.

6. Drain the used lubricant, clean the lubricant housing, and refill it.

7. Inspect for the presence of contaminants in pneumatic oil. Change it if required.

8. Replace all oil filters.

9. Run software simulations to check the alignment and indentation of tools.

10. Use software to quickly reverse the axis of the tool head to check for backlash. If the tool head experiences a backlash effect, further maintenance is required.

1. After starting the machine, it must be preheated for about 10 minutes before processing. Machines that will not be used for a long time should extend the warm-up time.

2. Check whether the oil circuit is smooth

3. Place the table and saddle in the center of the machine before shutting down the machine (move the three-axis travel to the middle of the travel of each axis).

4. Keep the machine tool dry and clean.

Note: The maintenance and repair of the equipment should be carried out by professional engineers.

1. The grounding protection system should have good continuity to ensure personal safety.

2. Regularly check the essential components such as circuit breakers, contactors, and single-phase or three-phase arc extinguishers. If the wiring is loose or the noise is too loud, find out the reasons and eliminate hidden dangers.

3. Make sure that the cooling fan in the electric cabinet operates normally, otherwise, it may cause damage to the vital components.

4. The fuse is blown and the air switch is frequently tripped. The cause should be found and eliminated in time.

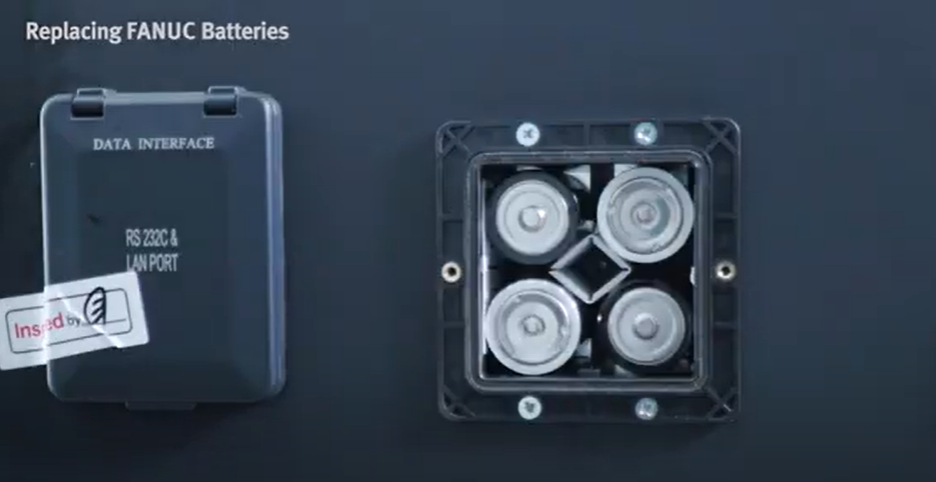

5. Servo drive battery replacement

The absolute control system data is maintained by the servo drive battery. When the battery voltage is too low (warning 9F), the drive battery must be replaced. Please order the same type of battery unit as soon as possible, and keep the drive power on. Please turn on the power of the drive unit 30 minutes before replacing the battery, and complete the battery replacement within 1 hour.

1. Confirm that the input power supply has been cut off and that the power supply of the replaced drive unit has been turned off.

2. Pull out the battery plug connected to the battery socket of the drive unit.

3. Press the side of the battery with your fingertips, push the battery horizontally, and then take it out.

4. Connect the plug of the new battery to the battery socket of the drive unit.

5. Install the battery on the drive unit.

On-site maintenance is to diagnose the failure of the CNC machine tool (mainly the CNC part), find the fault location, and replace it with the corresponding normal spare parts, so that the machine tool can resume regular operation.

The key to this process is the diagnosis, that is, to detect the system or peripheral circuits, determine whether there is a fault, and point out the exact location of the fault for fault location. From the positioning of the whole machine to the patch panel, in some cases, even to the components. This is the main part of the whole maintenance work.

Usually, when the data is relatively complete, the fault can be judged through data analysis, or the interface signal method can be used to judge the parts that may fail according to the fault phenomenon, and then check the parts one by one according to the specific characteristics of the fault and this part, and make a preliminary judgment.

In practical applications, it may be possible to use one method to find and eliminate faults, and sometimes multiple methods are required. The degree of mastery of various methods of judging fault points mainly depends on the depth of mastery of the principles and structures of faulty equipment.

When the numerical control system fails, the fault signal and corresponding information are generally given on the display screen or operation panel. Usually, the operation manual or adjustment manual of the system has a detailed alarm number, alarm content, and processing method.

Because the alarm settings of the system are single, complete, strict, and clear, maintenance personnel can handle them by themselves according to the information and processing methods given after each alarm.

According to the electrical characteristics of the machine tool, the machine tool manufacturer applies PLC programs to display some faults or operation information that can reflect the electrical control of the machine tool interface with specific signs, and give them through the display, and can see more detailed alarm descriptions through specific keys. This type of alarm can be handled according to the troubleshooting manual provided by the machine tool factory, or the operation panel or programmer can be used to find out the corresponding signal state according to the circuit diagram and PLC program, and find the fault point for processing according to the logical relationship.

Troubleshooting with no alarm or no alarm When the PLC of the system cannot be run, the system has stopped or the system does not alarm but works abnormally, it is necessary to analyze and make a decision based on the system status information before and after the failure and using the theoretical basis that has been mastered. correct judgment. This fault diagnosis and troubleshooting method are described below.

1. Visual inspection

Visually inspect the faulty board, carefully check whether there is a blown fuse, charred components, smoking, or cracking and whether there is a foreign body open circuit. In this way, it can be judged whether there are overcurrent, overvoltage, short circuits, and other problems in the board.

2. Touch

Touch and shake the components with your hands, especially the resistance, and capacitance, whether the semiconductor device has a loose feeling, so as to detect some problems of soldering.

3. Power-ups

First, use a multimeter to check whether there is an open circuit between various power supplies.

If there is no, you can connect to the corresponding power supply. Visually check whether there is smoke, ignition, etc., and touch the components for abnormal heat.

Failure, and narrow the scope of maintenance.

For example: when troubleshooting a factory in Harbin, the CNC system and PLC of the machine tool are running normally, but the hydraulic system of the machine tool cannot be started. Use the programmer to check that the PLC program is running normally and that the required signal states meet the startup conditions.

During further inspection, it was found that the PLC signal status was inconsistent with the markings on the drawings and equipment. The machine stopped and pulled out the circuit board for inspection. It was found that the address of the two output boards of the PLC was wrong, and the positions of the other two were wrong. After the exchange, the machine tool ran normally.

For the SIMATIC S5 programmable controller used by the machine tool with this failure, as long as the address is correct, no matter how the position of the circuit board is arranged, the system can run normally. Still, the corresponding executive components and signal sources must be correctly corresponding.

Corresponding errors will cause malfunctions and even destroy the machine tool. In addition, according to the failure phenomenon provided by the user, combined with their own on-site observation, and using the working principle of the system, a correct judgment can be made quickly.

4. System parameter check method

Nowadays, the self-diagnosis function of the operating system of CNC machine tools is getting stronger and stronger, and most of the faults of CNC machine tools can be diagnosed. When the CNC machine tool fails, sometimes the alarm information is displayed on the display, and sometimes there are alarm devices on the CNC device, the PLC device, and the drive device, such as the alarm light will flash, buzzer, and so on.

At this time, first, check the maintenance manual and check the corresponding parameter settings. The loss and incorrect setting of system parameters will cause the change or failure of the machine tool performance.

For example, in the automatic machining of the FANUC system, the machine tool rest stops moving and the screen displays 500 and 501 alarms. Check the parameter manually to find out that the corresponding parameters are stored stroke limit positive and negative limits. At this time, the machine tool can be changed to manual shaking. When the tool holder reaches the correct stroke range and corrects the parameters, the alarm can be removed.

5. Reset machine method

In the process of processing, due to the system alarm caused by the instantaneous fault, the fault can be cleared by hardware reset or turning on and off the system power in turn. The system must be initialized and cleared. Before clearing, you should pay attention to copying and recording important data. If the fault cannot be eliminated after initialization, perform hardware diagnosis.

6. Measurement diagnosis method

Measurement is the basic method for diagnosing equipment failures. We can use instruments such as multimeters, oscilloscopes, and logic testers to measure electronic circuits.

For example, when determining the phase sequence of the three-phase power supply of the numerical control system, the phase sequence table can be used for measurement, that is, the three-phase power line is connected to the phase sequence table. When the phase sequence is correct, the phase sequence table rotates clockwise, and vice versa. It can also be measured with a two-channel oscilloscope. If the phase sequence is correct, the waveforms of each two phase are 120° out of phase.

According to the system circuit diagram and machine tool circuit diagram, the voltage, power supply, pulse signal, etc. of the faulty part are measured to determine the fault. For example, the input voltage of the power supply exceeds the limit, causing the power supply monitoring to use a voltmeter to measure the network voltage or to use a voltage tester to monitor in real-time to eliminate other reasons.

If the position control loop fails, the oscilloscope can be used to check the signal state of the measurement loop, or the oscilloscope can be used to observe whether the signal output is phase-missing and whether there is interference.

For example, when a factory in Shanghai is troubleshooting, the system alarms, and the hardware of the position loop is faulty.

The oscilloscope is used to check and find that there is an interference signal. We use the method of connecting capacitors in the circuit to filter them out to make the system work normally.

When it comes to choosing a CNC machine (computer numerical control ), there are a few things you'll need to take into account in order to make sure you're getting the best possible option for your needs. In this blog post, we'll run through some of the key considerations you should keep in mind when making your decision. By the end, you should have a better understanding of what factors will influence your choice of CNC machine.

How to buy the right machine tool at the most reasonable price to consider the most critical factors? Here is a very useful checklist. Let's get started!

The expertise and proficiency of the machine operators will play a key role. You need to consider what your factory's current CNC machine setup looks like and how much experience your engineers and operators have with CNC machines.

If you already have existing machines, you should assess whether they are still fit for the purpose for which they were made, see where your current gaps lie, assess the life of your machines, and assess the cost-effectiveness of replacing your existing machines with newer, higher-performing machines.

In general, more automated smart machines require less human intervention than simple machine tools with limited functionality.

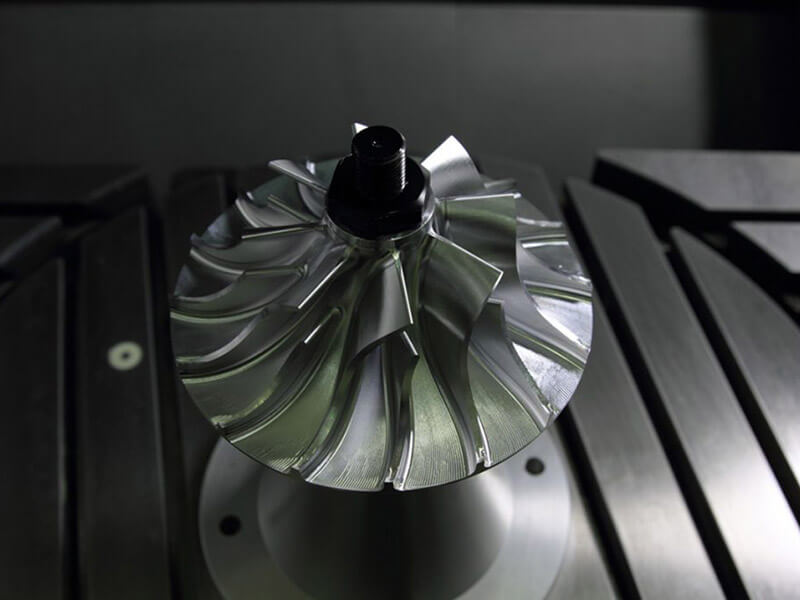

One of the biggest challenges of CNC machining is the complexity and precision of the parts to be produced.

The precision level of CNC machine tools determines the precision of the parts produced. CNC machine tools can be divided into simple type, full-function type, and precision type according to their machining accuracy. Three indicators to confirm the accuracy. The motion resolution of simple CNC machine tools is 0.01mm, while the precision of precision CNC machine tools is below 0.001mm.

Parts in the automotive, defense, aerospace or medical industries may require advanced CNC machine tools with a wide selection of spindles capable of manipulating, cutting, drilling, and forming parts with multi-axis control. Examples of these machines include 3 to 5-axis machining centers and 2 to 8-axis turning centers. They allow for one, two, or even multi-spindle (mass production) designs.

From standard jobs to highly complex jobs or mass production of complex parts, you can consider a horizontal or vertical CNC lathe with 2 to 5 axes or a CNC milling machine with 3 to 5 axes.

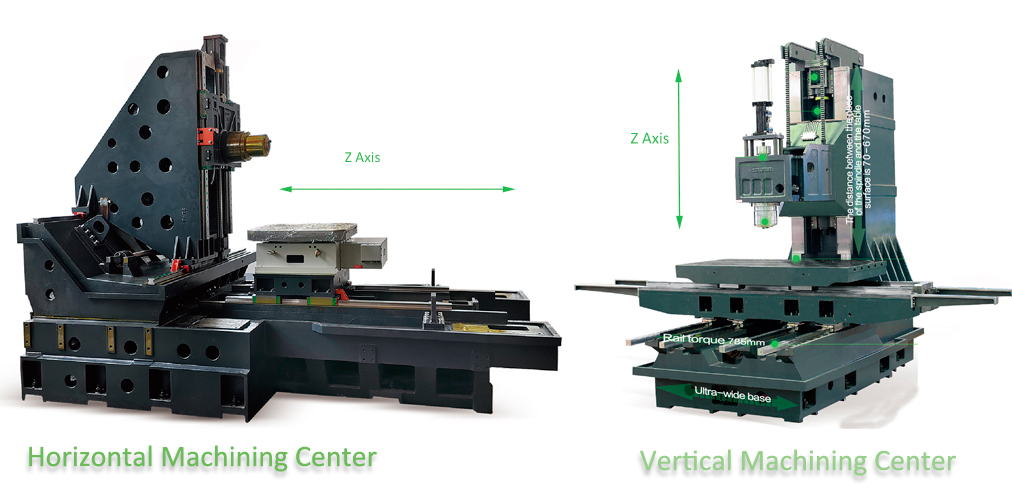

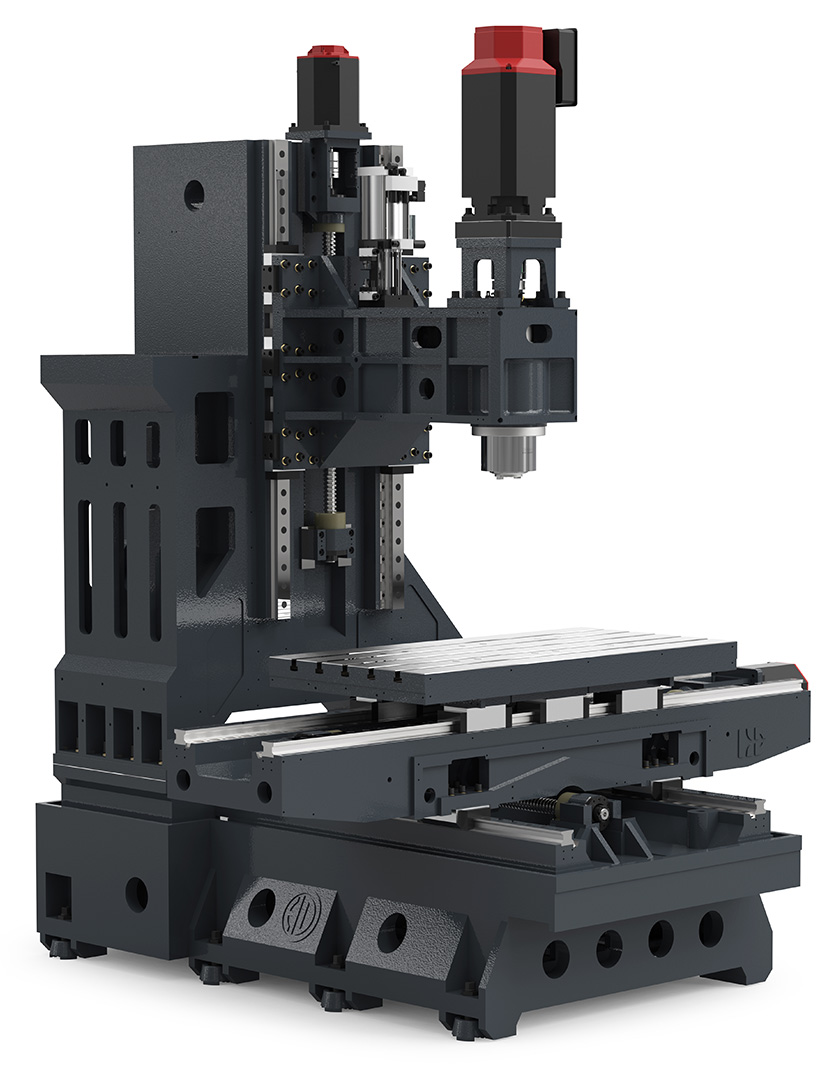

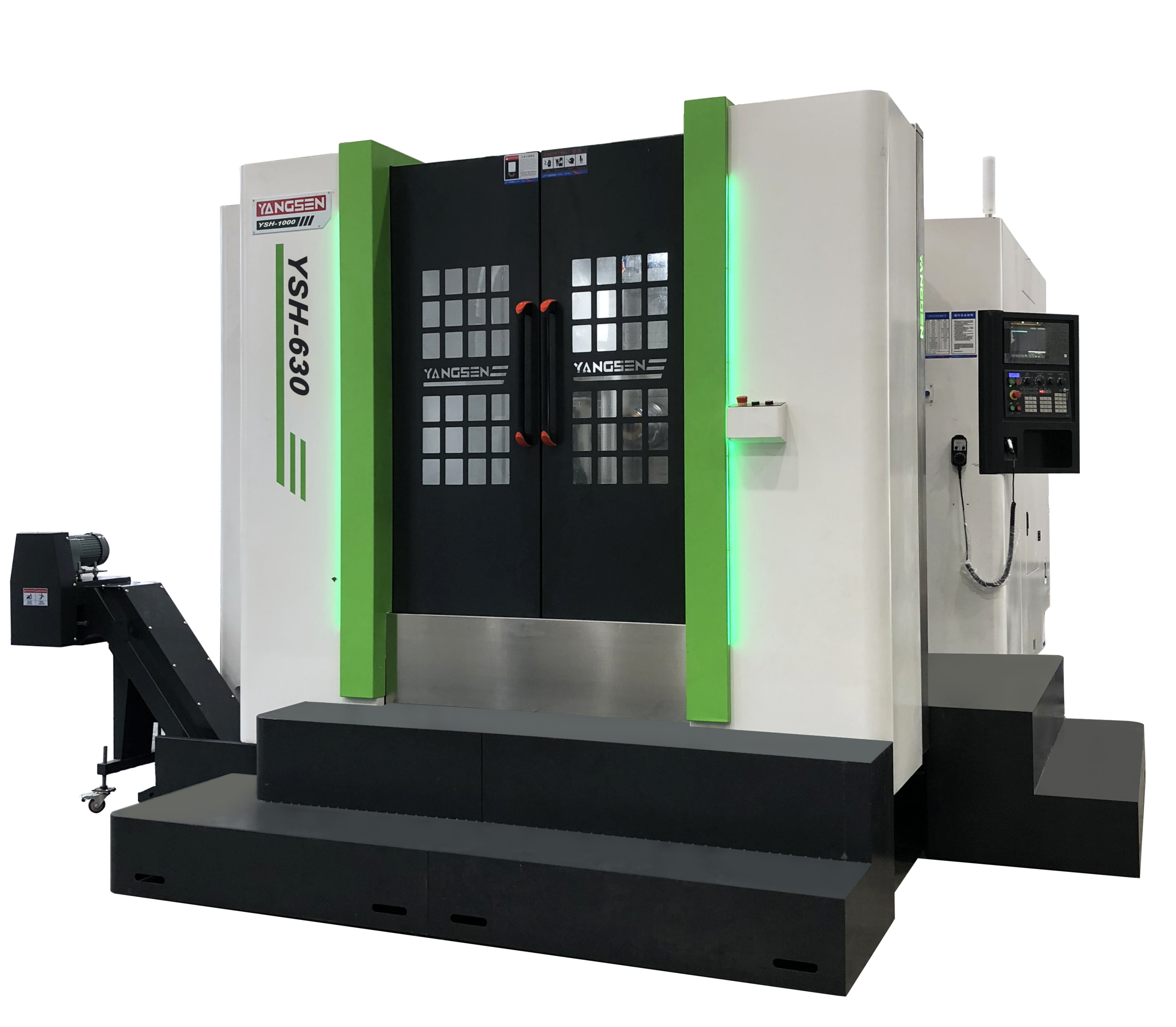

Yangsen has a range of horizontal machining centers to choose from:

The YSH series with a linear guide system is suitable for various applications and production needs. Available with 2 to 5 axes.

If the part is complex and needs to be done in one setup, a multi-axis turning center is a right choice.

Vertical lathes like Yangsen's YSL series are most effective for machining parts with a diameter much larger than the part's length. E.g., Gears, drums, discs, pump casings, engine casings, and rings, etc.

For the production of the fast turnaround of various parts and required machine settings in "High Mix – Small Batch" mode, Yangsen's new 5-axis machining center YS650-5AX offers an incredible solution with its ø650 mm 2-axis Table, 4+1 to full 5 axes and 4 optional spindles (option).

For the toughest materials such as titanium, Inconel, or heat-resistant stainless steel, the YS650-5AX ensures maximum stability and efficiency during simultaneous 5-axis cutting.

1. The high-speed cutting machine is used to complete a medium amount of milling, and then reduce the amount of grinding after milling to a minimum.

2. The CNC milling and machining center is processing equipment used to complete workpieces with a large amount of milling.

3. CNC engraving and milling machine is a processing equipment used to complete a small amount of milling or soft metal.

CNC machines are capable of machining almost most materials, including aluminum, copper, die or hardened steel, titanium, and Inconel.

When choosing a reliable CNC machine tool, you must first clarify your own processing requirements. The specifications and shapes of different parts vary greatly. Generally, the shape of the parts can be divided into plate type, box diamond type, flange shaft type, and special-shaped type. etc. In general, the main processing objects should be selected according to production requirements.

CNC machine tools are divided into roughing and finishing. After determining the parts to be processed, the process of the parts should be planned. When selecting CNC machine tools, their process adaptability should be exerted, and the maximum comprehensive processing ability of CNC machine tools should be exerted to ensure that the entire production process is complete. The process uses the least number of CNC machines and machining parts to maximize the variety of production parts.

The type of material being machined will affect the machine design and spindle selection, as well as the level of performance, durability, load bearing, and precision that can be achieved. The physical properties of the material and optimal cutting conditions also affect machine factors such as the required maximum spindle speed, peak spindle motor horsepower, and maximum spindle motor torque.

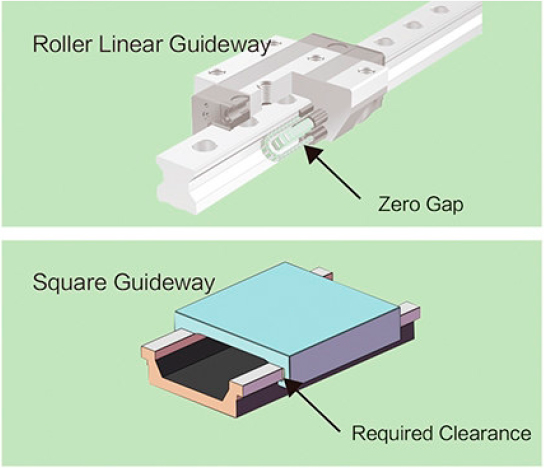

Next, you need to consider whether you should choose a CNC machine that uses a linear guide (LM) rail system, or a stronger, more rigid box rail design.

You need to consider four main factors here: speed, stiffness, load-carrying capacity, and tool life.

CNC machines built with LM guides tend to be faster but better suited for light-duty applications. On the other hand, machines with box rails are stronger, have less vibration, and are capable of making heavier cuts on large parts. However, these are generally slower than those with LM rails.

When choosing between the two, it's useful to ask yourself the following questions:

What is the material to be cut?

How much vibration damping is required?

What is the required cutting feed rate?

What is the expected and required tool life?

When choosing the right machine tool, you also need to match your choice with choosing the most practical CNC controller. This depends not only on the level of automation but also on the number of axes to be controlled and the manual intervention required in the production process. The semi-closed-loop numerical control system can automatically detect the position and compensate for the error. The fully closed-loop CNC system is the CNC system with the highest precision, but it is difficult to maintain and expensive.

The CNC system can control the processing and operation of CNC machine tools and can be called the core "brain" of CNC machine tools.

The open-loop CNC system is often used for CNC wire-cutting tools with low precision requirements. It does not have a position detection device and is positioned by the drive unit. It has the characteristics of low cost, simple structure, and low operation and maintenance.

In addition to choosing the best and largest screen for your CNC control, you should also consider the following important factors:

Reliability of CNC Control System

Effectiveness of Control

Software stability

User-friendliness - can you find the operators for these controls?

All CNC control systems of our CNC machines are the top 2 brands in the world. Fanuc and Siemens.

To determine this, you need to consider both fixed and variable costs:

Fixed costs: initial capital investment, machine depreciation, loan interest (if any)

Variable costs: material costs, labor costs, tool costs, tool change, maintenance and repair costs, spare parts costs

Note that choosing a cheaper machine does not necessarily guarantee you better productivity or plant profitability in the long run.

Weight is an important factor to consider when selecting a CNC machine, as it affects the overall stability of the machine and its ability to handle heavier loads.

A lighter machine will be more susceptible to vibration which can lead to inaccurate cuts and poor results. Additionally, a heavier machine may require stronger motors or other components in order to handle larger workpieces or for more accurate and precise cutting. Ultimately, selecting a CNC machine that has the right weight is important to ensure optimal performance and quality results from your machining operations.

We choose the best-built iron cast from the machine body, to guarantee enough stability and rigidity.

Last but not least, you need to consider how much space you have in your shop for a new machine.

Of course, this varies by industry and may include factors such as:

Make the most of available floor space

Minimize worker movement between machines

Material flow and space from point to point

Improve productivity

Chip processing

Safety conditions for workers

Room for future expansion

Available power points, and power requirements.

Yangsen has more than 20 years of experience in machine tool manufacturing and is one of the top 20 control machine tool manufacturers in China. Our CNC machines are widely used and provide an easy way to alleviate labor shortages. Send the CAD file to the machine, press four buttons, and the machine does the rest.

CNC machines are big investments. Hope the above suggestions can help you choose the right CNC machine tool. Contact Yangsen for more information.

Do I need a license to import CNC machine from China?

A: Yes, you need license to import CNC machine from China. If you don’t have license, you can find an agent or broker to help you clear customs and import.

How do you pack the CNC machine?

A: We pack the CNC machine with strong metal pallet or strong wooden container with fumigation stamp and cover with tarpaulin outside.

How we pack the CNC machine.

How it looks in containers.

How to transport CNC machine?

A: For CNC machine, usually the large size machine, we all suggest you choose SEA Freight for transportation, as it is the cheapest way for large format size goods.

Usually, it takes 10 days to South Eastern of Asia and it takes 30–42 days to the North America and European countries and it takes about 48-55 Days to South America countries.

If arrange the door-to-door transportation, we also supply DDP or DDU service.

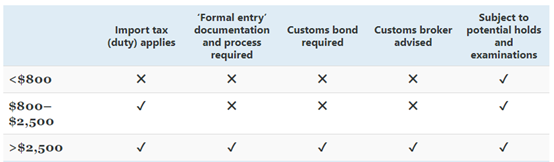

Do I have to pay import tax for CNC machine from China to us?

A: Yes, you need to pay taxes and duties. We can supply CO for you, it can relief some costs to import CNC machine.

The customs process, costs, and requirements vary depending on the value of your shipment, as shown below

How much is the tariff (Import Duty) for CNC machine?

A: The HS code for CNC Machines: 8456301090. Please see the Treaty Rate and RCEP Rate list as below:

|

Treaty Rate |

|

RCEP Rate |

|

|

Asean |

0% |

Australia |

5% |

|

Chile |

0% |

Brunei |

5% |

|

Pakistan |

4% |

Cambodia |

5% |

|

New Zealand |

0% |

Laos |

5% |

|

Peru |

0% |

Malaysia |

5% |

|

Costa Rica |

0% |

New Zealand |

5% |

|

Iceland |

0% |

Singapore |

5% |

|

Australia |

0% |

Thailand |

5% |

|

Mauritius |

0% |

Vietnam |

5% |

A: Once your machines have actually been gotten rid of with customs and all parties have been paid, the cargo needs to either be gotten or transferred to its last location.

Your machine would certainly arrive in a container with a range of various other deliveries if you shipped LCL (Less than Container Load). Commonly, after customs clearance, this container will be carried to a different place for destuffing. In these instances, you (or your freight forwarder) will be supplied with a secondary area near the original port.

If you shipped FCL (Full Container Load), the port of entry would be the location to utilize.

You’ll also be offered with a Cargo Control Number that serves as a one-of-a-kind identifier for your shipment. These details can then be utilized to get or ship the imported products.

Employing a cargo forwarder is the most usual means to take care of transportation to your final warehouse, workplace, or retail room. You can use a broker to arrange the domestic transportation.

You can bring your vehicle to the port or warehouse if you pick to get your items personally rather than have them delivered. Make sure to bring a percentage of cash to pay potential car parking, loading, and/or dock costs.

Please notice some machines may require the related document. Like laser machine importing requires FDA certificate.

Remember to get FDA certificate from the vendor before placing order.

Importing goods from China is a GREAT method to boost earnings while drawing from a diverse and large pool of products. Despite the cost of tariffs, transportation, and also customs, the low prices you’ll hop on Chinese imports makes the purchase process more than beneficial.

Commercial Invoice

Packing List

Origin of Certificate (If required)

Sales Contract

Bill of Lading

Operation Manuel

Product Certificate

Mechanical Manual

Electrical Manual

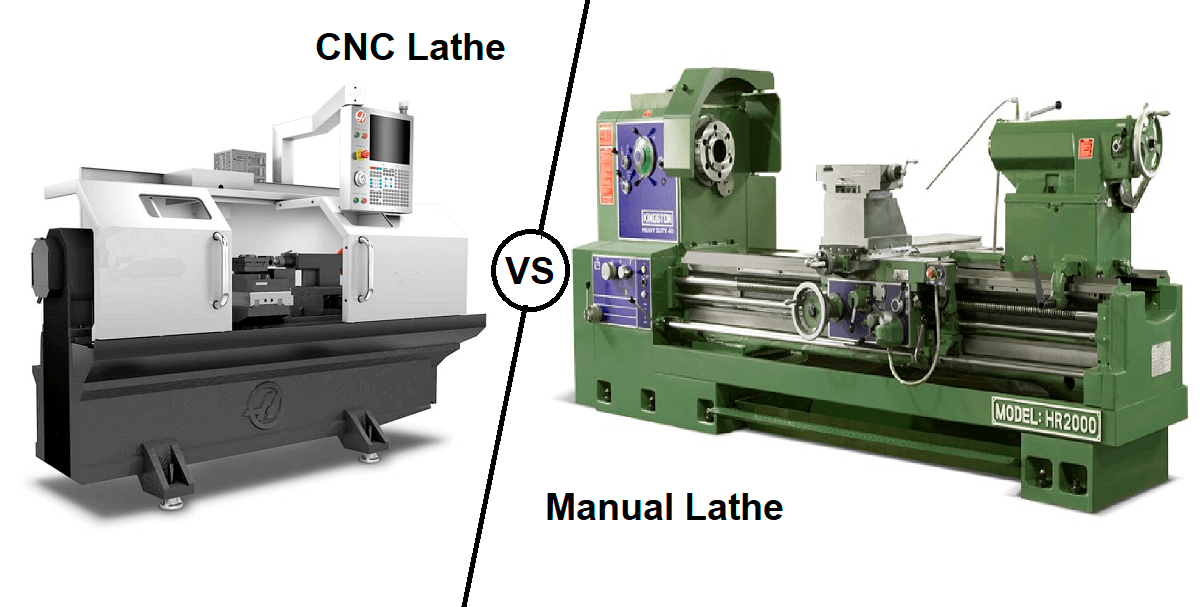

A CNC lathe is one of the most widely used CNC machine tools. It is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces of arbitrary taper angles, complex rotating inner and outer surfaces, and cylindrical and conical threads, etc., and can perform grooving, drilling, reaming, and reaming. Holes and borings, etc.

The CNC machine tool automatically processes the parts to be processed according to the pre-programmed processing program. We write the machining process route, process parameters, tool motion trajectory, displacement, cutting parameters, and auxiliary functions of the part into a machining program list according to the instruction code and program format specified by the CNC machine tool, and then record the content of the program list.

On the control medium, it is then input into the numerical control device of the numerical control machine tool, thereby directing the machine tool to process the parts.

Traditional machining is done by manual operation of ordinary machine tools. During machining, mechanical tools are shaken by hand to cut metal, and calipers and other tools are used to measure the accuracy of products.

Modern industries have already used computer numerically controlled machine tools for the operation, and CNC machine tools can automatically process any product and component directly according to the program pre-programmed by technicians. This is what we call CNC machining.

CNC machine tool is the abbreviation of digital control machine tool, which is an automatic machine tool equipped with a program control system. The control system can logically process the program specified by the control code or other symbolic instructions, and decode it, so as to make the machine tool move and process the parts.

Compared with ordinary machine tools, CNC machine tools have the following characteristics:

1. High processing precision and stable processing quality;

2. Multi-coordinate linkage can be carried out, and parts with complex shapes can be processed;

3. When the machining parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

4. The machine tool itself has high precision and rigidity and can choose favorable processing amount, and the productivity is high (generally 3~5 times that of ordinary machine tools);

5. The machine tool has a high degree of automation, which can reduce labor intensity;

6. Higher quality requirements for operators and higher technical requirements for maintenance personnel.

The CNC lathe is composed of a CNC device, bed, spindle box, tool post feed system, tailstock, hydraulic system, cooling system, lubrication system, chip conveyor, and other parts.

CNC lathes are divided into two types: vertical CNC lathes and horizontal CNC lathes.

Vertical CNC lathes are used for turning disc parts with large turning diameters.

Horizontal CNC lathes are used for turning long or small disc parts in axial size.

Horizontal CNC lathes can be further divided into economical CNC lathes, ordinary CNC lathes, and turning centers according to their functions.

Economical CNC lathe: a simple CNC lathe formed by transforming the turning feed system of an ordinary lathe by using a stepping motor and a single-chip microcomputer. The cost is low, the degree of automation and functions are relatively poor, and the turning accuracy is not high, and it is suitable for turning rotary parts with low requirements.

Ordinary CNC lathe: It is specially designed in structure according to the requirements of turning to process, and is equipped with a general CNC system. The CNC system has strong functions, a high degree of automation, and high machining accuracy, and is suitable for turning general rotary parts. This CNC lathe can control two coordinate axes at the same time, namely the x-axis and the z-axis.

Turning machining center: On the basis of ordinary CNC lathes, the C axis, and power head are added. More advanced machine tools also have tool magazines that can control three coordinate axes of X, Z, and C. The linkage control axis can be (X, Z), (X, C), or (Z, C). Due to the addition of the C-axis and milling power head, the processing function of this CNC lathe is greatly enhanced.

Hydraulic chuck and hydraulic tailstock

A hydraulic chuck is an important accessory for clamping workpieces during CNC turning. Common hydraulic chucks can be used for general rotary parts; special chucks are required for parts whose clamped parts are not cylindrical; Spring chucks are required when machining parts.

CNC lathes can be equipped with two tool holders:

①Special tool holder: It is developed by the lathe manufacturer itself, and the tool holder used is also dedicated. The advantage of this tool holder is that it is cheap to manufacture, but it lacks versatility.

②Universal tool holder: The tool holder is produced according to certain general standards (such as VDI, German Association of Engineers), CNC lathe manufacturers can choose and configure it according to the functional requirements of CNC lathes.

Milling power head

After installing the milling power head on the CNC lathe tool holder, the processing capacity of the CNC lathe can be greatly expanded. Such as axial drilling and milling of axial grooves with a milling power head.

CNC machines are available with programs that include numbers and letters, which can help to navigate parts around various distances. A machine programming language may be implemented on Gcode or a specialized language developed in manufacturing. Basic mills consist of three wheel-based systems (XY - Z) however newer mills may contain three more wheels in addition.

When turning parts on a CNC lathe or turning machining center, the position of the tool on the tool holder should be reasonably and scientifically arranged according to the tool holder structure of the lathe and the number of tools that can be installed, and attention should be paid to avoid the tool being stationary and working. Interference phenomenon with machine tools, tools and workpieces, and tools.

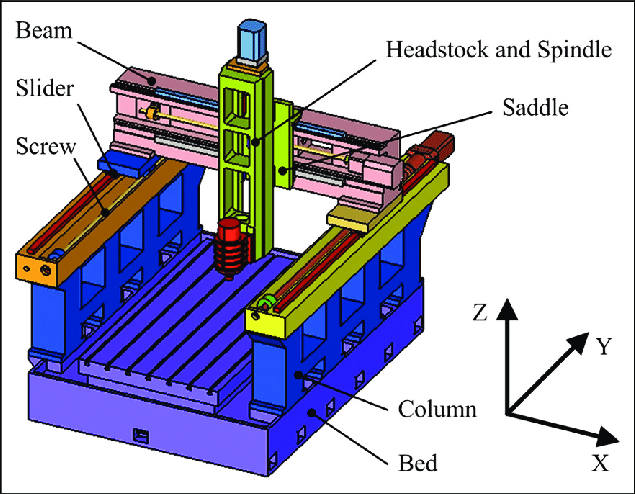

The host is the main body of the CNC machine tool, including the machine body, column, spindle, feed mechanism, and other mechanical components. It is a mechanical part used to complete various cutting operations.

The numerical control device is the core of the numerical control machine tool, including hardware (printed circuit board, CRT display, key box, paper tape reader, etc.) and corresponding software, which is used to input the digital part program and complete the storage of input information and data storage. Transform, interpolate, and implement various control functions.

The drive device is the drive component of the CNC machine tool actuator, including the spindle drive unit, the feed unit, the spindle motor, and the feed motor. He realizes the spindle and feed drive through the electric or electro-hydraulic servo system under the control of the numerical control device. When several feeds are linked, the processing of positioning, straight line, plane curve, and space curve can be completed.

Auxiliary devices, some necessary supporting components of the index control machine tool, to ensure the operation of the CNC machine tool, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange tables, CNC turntables, and CNC indexing heads, as well as tools and monitoring and testing devices.

The lifting and positioning of the machine tool should use the special lifting tools provided by the manufacturer, and other methods are not allowed. No special hoisting tools are required, and steel wire ropes should be used to hoist and position according to the specified parts of the manual.

The machine tool should be installed on a solid foundation, and the location should be away from the vibration source; avoid sunlight and heat radiation; place it in a dry place to avoid the influence of moisture and airflow. If there is a vibration source near the machine tool, an anti-vibration trench must be set around the foundation.

The machine tool is placed on the foundation, it should be leveled in a free state, and then the anchor bolts are evenly locked. For ordinary machine tools, the level reading does not exceed 0.04/1000mm, and for high-precision machine tools, the level does not exceed 0.02/1000mm.

When measuring the installation accuracy, it should be carried out at a constant temperature, and the measuring tool should be used after a period of constant temperature. When installing the machine tool, try to avoid installation methods that force the machine tool to deform. When the machine tool is installed, some parts of the machine tool should not be removed casually. The removal of the parts may lead to the redistribution of the internal stress of the machine tool, thus affecting the accuracy of the machine tool.

After the geometric accuracy of the machine tool has passed the inspection, the whole machine needs to be cleaned. Use cotton or silk cloth soaked with the cleaning agent, not cotton or gauze. Clean off the anti-rust oil or anti-rust paint applied to protect the guide rail surface and the machined surface when the machine tool leaves the factory. Clean the dust from the outer surface of the machine tool. Coat each sliding surface and working surface with lubricating oil specified by the machine tool.

Carefully check whether all parts of the machine tool are oiled as required and whether enough coolant is added to the cooling box. Whether the oil of the hydraulic station of the machine tool and the automatic lubricating device has reached the specified position of the oil level indicator.

Check whether the switches and components in the electrical control box are normal and whether the integrated circuit boards are in place.

Turn on the power and start the centralized lubrication installation, so that the lubricating parts and the lubricating oil circuit are filled with lubricating oil. Do all the preparations before the action of each part of the machine tool.

Since CNC lathe processing is a high-precision work, its processing procedures are concentrated and the number of parts clamping is small, which puts forward higher requirements for the CNC tools used. The following Dongguan Tongli Metal Products Co., Ltd. is here for you. introduce.

When choosing tools for CNC machine tools, the following aspects should be considered:

① The type, specification, and precision grade of CNC tools should be able to meet the processing requirements of CNC lathes.

②High precision. In order to meet the requirements of high precision and automatic tool change of CNC lathe processing, the tool must have high precision.

③High reliability. To ensure that accidental tool damage and potential defects do not occur in CNC machining and affect the smooth progress of machining, it is required that the tool and the accessories combined with it must have good reliability and strong adaptability. Precision metal processing

④High durability. The tools processed by CNC lathes, whether in roughing or finishing, should have higher durability than those used in ordinary machine tools, so as to minimize the number of replacement or grinding tools and tool settings, thereby improving the processing of CNC machine tools. Efficiency and guaranteed processing quality.

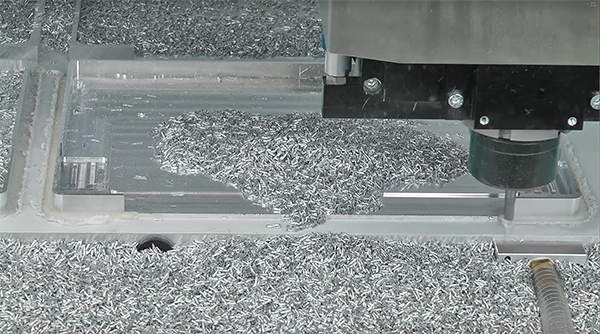

⑤ Good chip breaking and chip evacuation performance. In CNC lathe processing, chip breaking and chip removal cannot be handled manually like ordinary machine tools.

The chips are easy to wrap around the tool and the workpiece, which will damage the tool and scratch the machined surface of the workpiece, and even cause injuries and equipment accidents. , affecting the processing quality and the safe operation of the machine tool, so the tool is required to have good chip breaking and chip removal performance.

In hardware processing, all rotary parts that can be clamped on an ordinary lathe can be processed on a CNC lathe. However, CNC lathes have the characteristics of high machining accuracy, linear and circular interpolation, and automatic speed change in the process of hardware processing, and their technological scope is much wider than that of ordinary machine tools.

The CNC lathe has good rigidity, high manufacturing, and tool setting accuracy, and can easily and accurately enter manual compensation and automatic compensation. Therefore, it can process parts with high dimensional accuracy requirements.

In addition, the tool movement of CNC turning is realized by high-precision interpolation movement and servo drive.

In addition, the rigidity of the machine tool is good and the manufacturing precision is high. Therefore, it can process the shape accuracy of the busbar straightness, roundness, cylindricity, etc. Demanding parts. For arcs and other curved profiles, the machined shape is much closer to the geometry required on the drawing than with a copy lathe.

The CNC lathe has a constant line speed cutting function, so the optimal line speed can be used to cut the tapered surface and the end surface, so that the surface roughness value after turning is small and consistent, and the parts with small and uniform surface roughness value can be processed.

The location of the machine tool should be far away from the vibration source, direct sunlight and thermal radiation should be avoided, and the influence of humidity and airflow should be avoided. If there is a vibration source near the machine tool, anti-vibration grooves should be set around the machine tool.

Otherwise, it will directly affect the machining accuracy and stability of the machine tool, which will cause poor contact with the electronic components, failure, and affect the reliability of the machine tool.

Generally, CNC lathes are installed in the machining workshop, not only does the ambient temperature change greatly, and the use conditions are poor, but also there are many mechanical and electrical equipment, resulting in large fluctuations in the power grid. Therefore, the location where the CNC lathe is installed requires strict control of the power supply voltage. Power supply voltage fluctuations must be within the allowable range and remain relatively stable. Otherwise, the normal operation of the CNC system will be affected.

The ambient temperature of the CNC lathe is lower than 30 degrees Celsius, and the relative temperature is less than 80%.

Generally speaking, there is an exhaust fan or a cooling fan inside the CNC electric control box to keep the working temperature of the electronic components, especially the central processing unit, constant or the temperature difference changes very little.

When using the machine tool, the user is not allowed to change the parameters set by the manufacturer in the control system at will. The setting of these parameters is directly related to the dynamic characteristics of each component of the machine tool. Only the backlash compensation parameter values can be adjusted according to the actual situation.

The user cannot change the accessories of the machine tool at will, such as using the hydraulic chuck beyond the specification. The manufacturer fully considers the matching of various link parameters when setting accessories. Blind replacement results in a mismatch of parameters in various links, and even cause unexpected accidents.

The pressure of the hydraulic chuck, hydraulic tool rest, hydraulic tailstock, and hydraulic cylinder should be within the allowable stress range, and it is not allowed to increase arbitrarily.

CNC lathe is a high-precision, high-efficiency automatic machine tool. Equipped with a multi-station turret or a power turret, the machine tool has a wide range of processing performance, which can process linear cylinders, oblique cylinders, arcs, and various threads, grooves, worms, and other complex workpieces, with linear interpolation, arc Interpolate various compensation functions, and play a good economic effect in the mass production of complex parts. The maintenance of the CNC lathe with the inclined bed is as follows:

In order to ensure the working accuracy of the CNC lathe with an inclined bed and prolong the service life, it is necessary to carry out reasonable maintenance work on the CNC lathe with an inclined bed for self-use.

In order to use CNC lathes one must be able to successfully complete a specified amount of courses and obtain appropriate certification. CNC turning machining programs usually include multiple class sessions that offer a gradual instruction program split into several sections. Throughout the training, a safety protocol should be respected. Beginning machining classes can be difficult without practical experience, but they can help familiarize the students with the commands in CAD files and CAD programming.

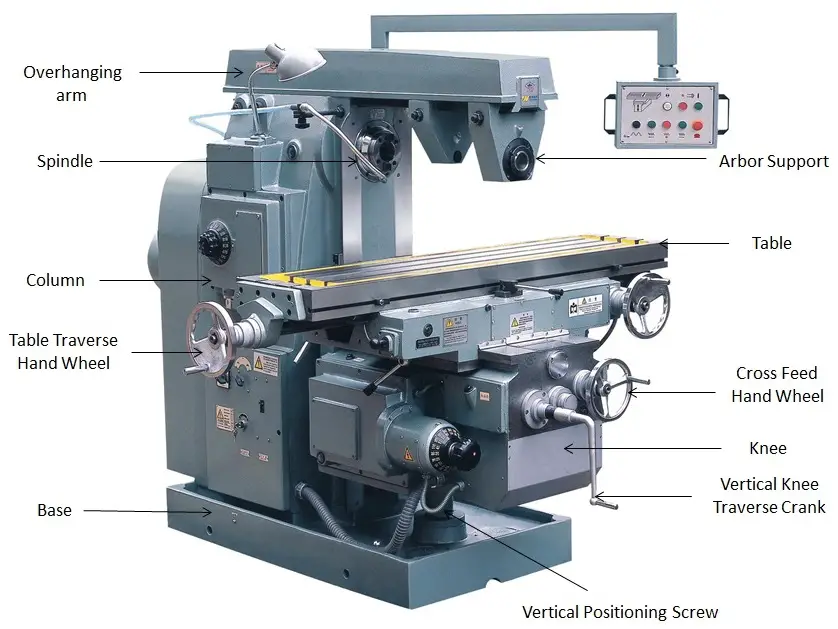

A milling machine mainly refers to a machine tool that uses a milling cutting tool to process various surfaces of workpieces. Usually, the rotary motion of the milling cutting tool is the main motion, and the movement of the workpiece and the milling cutting tool is the feed motion. It can process planes, grooves, various curved surfaces, gears, etc. In addition to milling planes, grooves, gear teeth, threads, and spline shafts, milling machines can also process more complex profiles, with higher efficiency than planers, and are widely used in machinery manufacturing and repair departments.

Moreover, it can also be used to process the surface of the revolving body, the inner hole, and the cutting work. When the milling machine is working, the workpiece is mounted on the table or the accessories such as the indexing head. The rotation of the milling cutter is the main movement, supplemented by the feed movement of the table or the milling head, and the workpiece can obtain the required machining surface.

Due to the multi-blade interrupted cutting, the productivity of the milling machine is high. In simple terms, a milling machine is a machine tool that can mill, drill, and bore a workpiece.

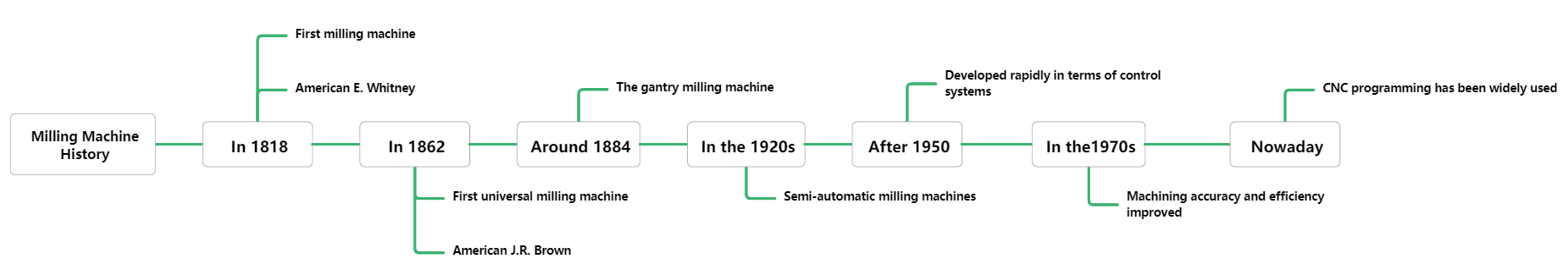

In 1818: the first milling machine was a horizontal milling machine created by American E. Whitney.

In 1862: To mill the spiral groove of the twist drill, American J.R. Brown created the first universal milling machine, which was the prototype of the milling machine for the lifting table.

Around 1884: the gantry milling machine appeared.

In the 1920s: semi-automatic milling machines appeared, and the worktable used stops to complete the automatic conversion of "feed-fast" or "rapid-feed".

After 1950, milling machines developed rapidly in terms of control systems, and the application of digital control greatly improved the automation of milling machines.

Especially after the 1970s, the digital control system and automatic tool change system of the microprocessor were applied to the milling machine, which expanded the machining range of the milling machine and improved the machining accuracy and efficiency.

With the continuous intensification of the mechanization process, CNC programming has been widely used in machine tool operations, which has greatly released the labor force. CNC programming milling machines will gradually replace manual operations. The requirements for employees will also be higher and higher, and of course, the efficiency will be higher and higher.

There are universal, horizontal and vertical, etc., mainly used for processing small and medium-sized parts, the most widely used.

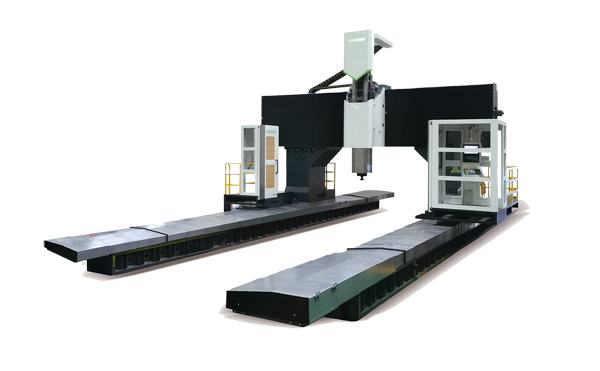

Gantry milling and boring machines, gantry milling planers, and double-column milling machines, all of which are used to process large parts.

The horizontal milling head of the former can move along the column guide rail, and the worktable is fed longitudinally; the end milling head of the latter can move horizontally along the cantilever guide rail, and the cantilever can also adjust the height along the column guide rail. Both are used for machining large parts.

There are two types of rectangular tables and circular tables, which is a medium-sized milling machine between the lifting table milling machine and the gantry milling machine. Its vertical movement is completed by the milling head rising and falling on the column.

A small lift table milling machine for machining instrumentation and other small parts.

Used for mold and tool making, equipped with various accessories such as end milling head, universal angle table, and plug, and can also perform processing such as drilling, boring, and plunging.

such as keyway milling machines, cam milling machines, crankshaft milling machines, roll journal milling machines, and square steel ingot milling machines, etc., are special milling machines manufactured for processing corresponding workpieces.

a small milling machine used for milling small parts such as instruments and meters.

a milling machine with the milling head mounted on the cantilever, the bed is arranged horizontally, the cantilever can generally move vertically along the column guide rail on one side of the bed, and the milling head moves along the cantilever guide rail.

a milling machine with the spindle mounted on the ram.

The machine body is arranged horizontally, and the columns and connecting beams on both sides form the gantry milling machine. The milling head is mounted on the beam and column and can move along its guide rails. Usually, the beam can move vertically along the guide rail of the column, and the worktable can move vertically along the guide rail of the bed for processing large pieces.

a milling machine for milling planes and forming surfaces.

a milling machine that copies the workpiece. Generally used for machining complex shape workpieces.

a milling machine with a lifting table that can move vertically along the guide rail of the bed. Usually, the worktable and the saddle installed on the lifting table can move longitudinally and laterally, respectively.

The rocker arm milling machine can also be called a turret milling machine, a rocker arm milling machine, and a universal milling machine. The turret mills machine of the machine tool is a light general metal cutting machine tool with two functions vertical and horizontal milling. Flat surface, bevels, grooves, and splines for small parts, etc.

The worktable cannot be raised and lowered but can be moved longitudinally and laterally along the guide rail of the bed base, and the milling head or column can be moved vertically.

Such as tool milling machines: are milling machines used for milling tools and molds, with high machining accuracy and complex machining shapes.

Milling machines can be divided into:

copy milling machines,

program-controlled milling machines

CNC milling machines.

To be used for machining planes, steps, grooves, forming surfaces, and cutting workpieces on milling machines.

There are many commonly used types of milling cutters according to their uses:

Used for machining planes on horizontal milling machines. The cutter teeth are distributed on the circumference of the milling cutter and are divided into straight teeth and helical teeth according to the tooth shape. According to the number of teeth, there are two kinds of coarse teeth and fine teeth. The helical-tooth coarse-tooth milling cutter has few teeth, high tooth strength, and large chip space, which is suitable for rough machining; the fine-toothed milling cutter is suitable for finishing.

used for vertical milling machines, face milling machines or gantry milling machines, upper processing plane, there are cutter teeth on the end face and circumference, and there are coarse teeth and fine teeth. Its structure has three types: integral type, insert type, and indexable type.

used for machining grooves and stepped surfaces, etc. The cutter teeth are on the circumference and end face, and cannot be fed in the axial direction during the end milling operation. When the end mill has end teeth that pass through the center, it can be fed axially (usually double-edged end mills are also called "keyway mills" and can be fed axially).

It is used to process various grooves and stepped surfaces, and there are cutter teeth on both sides and on the circumference.

used for milling grooves at a certain angle, there are two types of single-angle and double-angle milling cutters.

It is used for machining deep grooves and cutting workpieces, and there are more teeth on its circumference. In order to reduce friction during milling, there are 15' to 1° secondary declinations on both sides of the cutter teeth. In addition, there are keyway milling cutters, dovetail milling cutters, T-slot milling cutters, and various forming milling cutters.

The cutter teeth are made of cemented carbide or other wear-resistant tool materials and are brazed on the cutter body.

The cutter teeth are fastened on the cutter body by mechanical clamping. The replaceable teeth can be a head of a solid tool material or a head of a welded tool material. The milling cutter with the cutter head mounted on the cutter body is called the internal grinding type; the cutter head is sharpened separately on the fixture is called the external grinding type.

This structure has been widely used in face milling cutters, end milling cutters, and three-side edge milling cutters.

Metal cutting machine tools have implemented the export product quality licensing system, and products that have not obtained the export product quality license are not allowed to be exported. When ordering, the equipment parameters, metric and inch system, power supply, voltage, and frequency, as well as random accessories, the color of the machine tool, etc. must be clearly specified. In view of the wide variety of CNC punch presses and different standards in the sheet metal industry, when customers order molds, they should learn the following information from the manufacturer:

determine which of the long guide or short guide type the mold structure is and whether it is an imported Murata structure or a Trumpf structure or Yangsen Structure;

whether the punching force of this mold is suitable for this machine tool, otherwise, the structure of the mold must be changed or other processing methods must be selected;

if the machine station is a non-rotating station, the double keyway structure must be considered for the guide bush or the lower die;

in order to determine the height of the lower mold of the mold (forming mold);

the material and thickness of the sheet processed by the customer must be determined to determine the material and gap selected for the mold;

the direction of the positioning pin (slot) of the mold (especially the special-shaped mold) should be determined according to the customer's processing requirements. In addition, except for the square edge mold, the guide sleeve or lower mold of the other molds must consider two keyways;

There are many types of molds, and it is necessary to clarify the type of mold ordered by the customer.

1. When loading and unloading the workpiece, the tool must be removed, and the cutting head and hand should not be close to the milling surface.

2. When using a milling machine for tool setting, it must be jogged or hand-cranked, and fast forward is not allowed.

3. When advancing and retracting the tool quickly, pay attention to whether the handle of the milling machine will hit someone.

4. Do not feed too fast, and do not change speed suddenly, and the limit stop of the milling machine should be adjusted well.

5. The Asahi milling machine must be stopped when moving up and down, measuring the workpiece, adjusting the tool, and tightening the speed change.

6. When disassembling and assembling the end mill, the work surface should be padded with wooden boards, the pulling out of the flat mill should be disassembled, and the force should not be excessive.

7. It is strictly forbidden to touch or wipe the rotating parts and knives with cotton yarn.

8. In general, a collet can only clamp one workpiece at a time. Because a collet clamps more than one workpiece at a time, even if the clamp is tight, the force during rough feeding is very large, and the two workpieces are easy to slide between them, causing the workpiece to fly out, the knife is broken, and the injury accident.

1. Cleaning of bed and components, cleaning of iron filings, and sanitation of surrounding environment;

2. Check the oil level, not lower than the oil mark, and add lubricating oil to each part;

3. Cleaners, clamps, and measuring tools.

1. Clean and adjust the workbench, screw handle, and column inserts;

2. Check and adjust the clutch;

3. Clean three-way guide rails and linoleum, clean the inside and outside of motors, machine tools, and accessories;

4. Check the oil circuit and add lubricating oil to all parts;

5. Tighten all screws.

1. Cleaning of bed and parts, cleaning iron filings and surrounding environment, cleaners, clamps, measuring tools;

2. Check the oil level, not lower than the oil mark, and add lubricating oil to each part.

1. Disassemble and clean the oil felt pads of various parts;

2. Wipe each sliding surface and guide rail surface, wipe the table and the horizontal direction, lift the screw, wipe the knife transmission mechanism and the knife rest;

3. Wipe all corners.

1. All oil holes are clean and unobstructed and lubricating oil is filled;

2. Lubricating oil is added to each guide rail surface, sliding surface and each screw rod;

3. Check the transmission mechanism oil tank body, and oil level, and refuel to the elevation position.

1. Check and tighten the pressure plate and insert screws;

2. Check and tighten the fixing screws of the slider, the driving mechanism of the knife, the handwheel, the screws of the working table bracket, and the fork top wire;

3. Check and tighten other loose screws.

1. Check and adjust the tightness of belts, pressure plates, and inserts for a proper fit;

2. Check and adjust the sliding block and lead screw.

1. Remove the rust from each part, protect the painted surface, and do not collide;

2. Deactivation, spare equipment guiding rail surface, sliding screw handwheel and other exposed parts that are easy to rust are oiled and anti-corrosion.

Most of the gantry milling machines are made of steel or cast iron. In the long-term use process, due to the friction between the two contact surfaces of different degrees, the surface of the milling machine guide rail will be worn to different degrees, which will seriously affect the machining accuracy and production efficiency of the equipment.

Traditional repair methods usually use metal plate affixing or replacement, but require a lot of precise tolerances manufacturing and manual scraping, repairing requires many processes and a long construction period. The problem of scratches and strains on the gantry milling machine can be solved by using polymer composite materials, among which there should be a mature technology system.

Due to the material's excellent adhesion, compressive strength, and oil and wear resistance, it provides a long-lasting protective layer for components. It only takes a few hours to repair the scratched part of the machine tool and put it into use. Compared with the traditional method, the milling operation is simpler and the cost is lower.

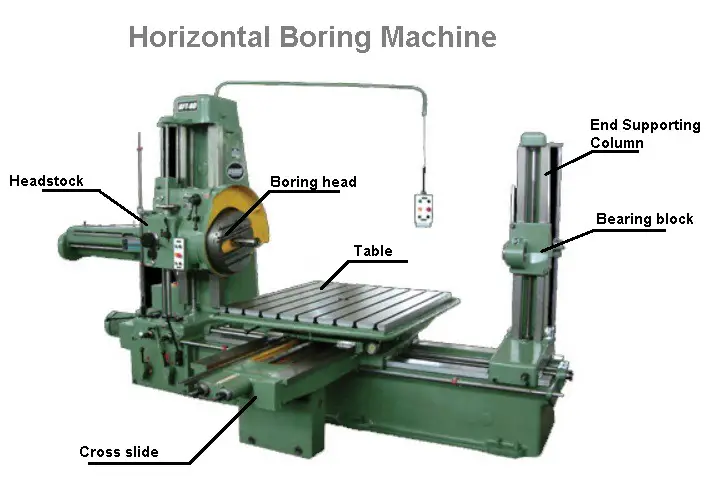

The development of horizontal boring and milling machines has attracted much attention because of its injection of the concept of acceleration. The transmission elements, such as electric spindles, linear motors, and linear guides, which are technical support for high-speed milling operation, have been widely used, pushing the running speed of the machine tool to a new height. The innovative design of the spindle-replaceable horizontal boring-milling machining center solves the disadvantages of the electric spindle and the boring bar mobile telescopic structure. Technological innovation.

The development of floor-type milling and boring machines leads to the trend of modern processing with its new design concept. The structure type with no boring shaft ram type and various milling heads exchanged with the concept of high-speed processing are full of style, which can greatly replace traditional milling processing. the trend of. Various milling head accessories represented by the two-coordinate swing angle milling head have become the main means to achieve high-speed and high-efficiency composite machining. Its process performance is wider, the power is higher, and the rigidity is stronger, which is a major breakthrough in the development of floor milling and boring machines.

The main key component of the horizontal boring and milling machine is the spindle box, which is installed on the side of the column. There are also a few manufacturers who use the double-column thermal symmetry structure, placing the spindle box in the middle of the column. The biggest feature of this structure is rigidity, balance, and good heat dissipation performance, which provides a reliable guarantee for the high-speed operation of the headstock. However, the double-column structure is inconvenient for maintenance, which is the reason why there are not many manufacturers using it today. The movement of the spindle box is mostly driven by the motor-driven ball screw, which is the core transmission device of the spindle drive. As the spindle speed is getting higher and higher and the spindle heats up quickly, many manufacturers have adopted oil mist cooling instead of oil cooling to more effectively control the spindle temperature and ensure its accuracy.

There are two main types of spindle systems, one is the traditional boring bar telescopic structure, which has the characteristics of deep hole boring and high-power cutting; the other is the modern high-speed electric spindle structure, which has high speed, fast running speed, and high efficiency, the advantages of high precision.

There are more and more applications of high-speed motorized spindles on horizontal boring and milling machines. In addition to greatly improving the speed and accuracy of the spindle, it also simplifies the internal structure of the headstock and shortens the manufacturing cycle, especially for high-speed cutting.

Larger than 10000r/min. The disadvantage is that the power is limited, its manufacturing cost is high, especially deep hole machining cannot be performed. The boring bar telescopic structure has limited speed, and the accuracy is not as good as that of the electric spindle structure, but it can carry out deep hole processing, has high power, can perform full-load processing, and has high efficiency, which is unmatched by the electric spindle. Therefore, the two structures coexist with different process performances but provide users with more choices.

A replaceable spindle system has also been developed, which has the function of one machine and two functions. Users can choose to use it according to different processing objects, that is, the electric spindle and the boring bar can be replaced with each other. This structure takes into account the shortcomings of the two structures, and also greatly reduces the cost. It is a great innovation of today's horizontal boring and milling machine. The advantages of the electric spindle lie in high-speed cutting and rapid feed, which greatly improves the precision and efficiency of the machine tool.

The running speed of the horizontal boring and milling machine is getting higher and higher, the fast-moving speed reaches 25-30m/min, and the maximum speed of the boring bar is 6000r/min. The speed of the horizontal machining center is higher, the rapid movement is as high as 50m/min, the acceleration is 5m/s2, the position accuracy is 0.008 ~ 0.01mm, and the repeated positioning accuracy is 0.004 ~ 0.005mm.

Since the floor milling and boring machine mainly process large parts, the milling process has a wide range, especially high-power and powerful cutting is a major processing advantage of the floor milling and boring machine, which is also the traditional process concept of the floor milling and boring machine. The technological development of contemporary floor milling and boring machines is changing the traditional process concept and processing method. The process concept of high-speed machining is replacing the traditional heavy-cutting concept, bringing about changes in processing methods with high speed, high precision, and high efficiency, which also promotes the structural change of the floor-type milling and boring machine and the improvement of the technical level.

Today, the biggest feature of the development of floor-type milling and boring machines is the development of high-speed milling, all of which are ram-type (without boring shaft) structures and equipped with various milling head accessories with different process performances. The advantages of this structure are that the ram has a large cross-section, good rigidity, long stroke, and fast-moving speed, and it is easy to install various functional accessories, mainly high-speed boring, milling head, two-coordinate double swing angle milling head, etc. The performance and processing range have reached the extreme, greatly improving the processing speed and efficiency.

Traditional milling is processed by boring bars, while modern milling is mostly completed by various functional accessories through rams. There is a trend to replace traditional processing. Its advantages are not only the speed and efficiency of milling but also the ability to carry out the processing of polyhedrons and curved surfaces cannot be accomplished by traditional processing methods. Therefore, many manufacturers are competing to develop and produce ram-type (without boring shaft) high-speed machining centers, because of their economic and technical advantages, and can greatly improve the technological level and technological scope of machine tools. At the same time, the machining accuracy and machining efficiency are improved. Of course, various types of high-precision milling head accessories are needed for technical support, and the requirements are also very high.